SMS group has developed a new simulation model for directube® copper tube plants that aims to significantly improve the efficiency of automation projects. By conducting functional simulations, the functions and behavior of a machine and its control systems can be comprehensively tested and their virtual commissioning carried out. It provides a protected space in which the interaction of the individual plant components can take place and be analyzed safely and without any risk to the real plant. The programmers can repeat, reset, or save the control sequences as often as they need to gain a full understanding of the plant’s control and operation.

A highly advanced process model

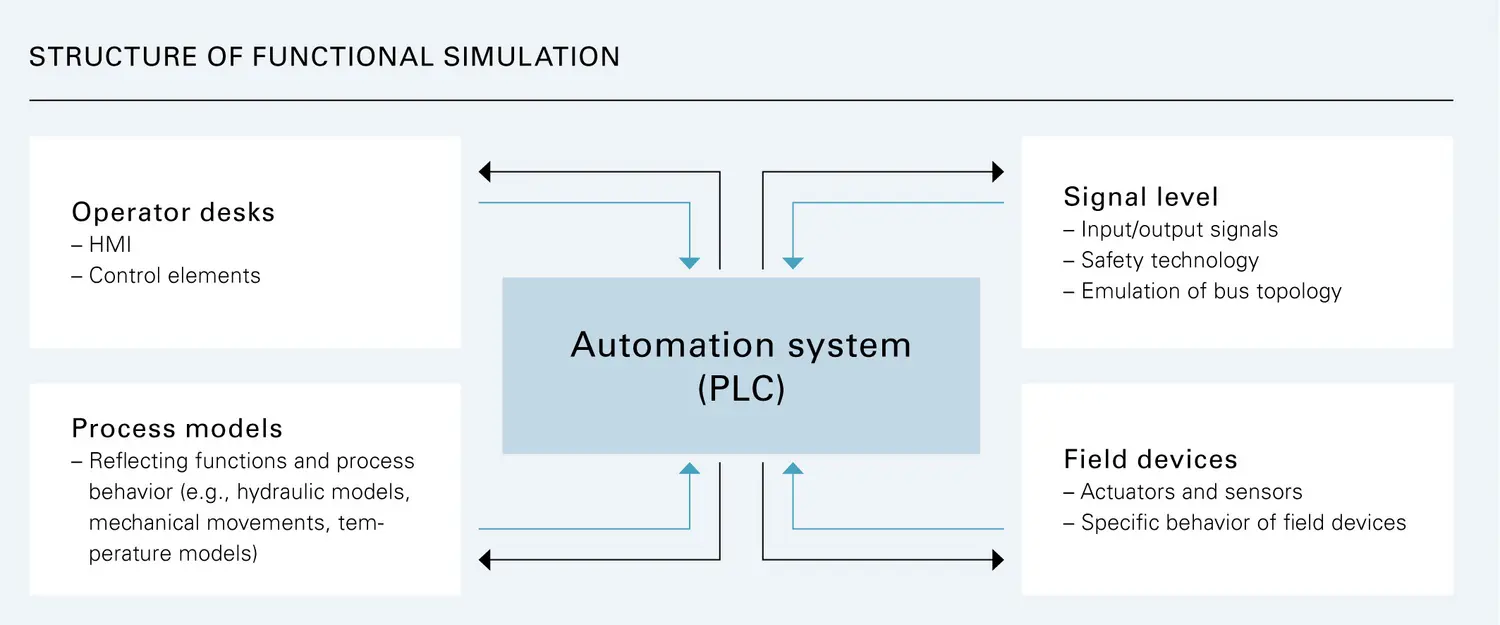

The centerpiece of the functional simulation is new software that simulates the operation and simplified physical behavior of the entire directube® plant and, in particular, its electrical control components. This model includes a variety of components, including frequency converters, safety technology, and bus topology, and it integrates all key actuators and sensors to provide a comprehensive simulation experience.

Significantly accelerating commissioning

This innovative simulation tool from SMS group is used before the actual plant is brought on stream. Testing all of the control system’s major functions beforehand under simulated conditions can significantly reduce commissioning times. A functional simulation identifies and eliminates possible fault sources in advance, thus enabling specific optimizations to be made. For example, by deactivating a sensor via the software, a programmer can observe how the plant control system responds to its failure. This enables programmers to take appropriate corrective action earlier on and in a more targeted manner.

As a result, simulations play a vital role in ensuring that the control and visualization software is complete and free from errors before it is used in practice. This in turn minimizes potential plant downtimes.

Knowledge transfer

Another significant advantage is that SMS group can also involve employees around the world through remote training using the simulation software. This early training guarantees that at the time of commissioning the technicians are up to speed and ready to start up the plant and address any challenges directly. The comprehensive knowledge transfer and targeted training ensure that qualified SMS experts are on hand in all countries to assist and support customers during and after commissioning. The principle of functional simulation will be applied in other product lines obtaining efficiency improvements across the SMS portfolio.

How directube® works

The directube® process developed by SMS group enables the particularly efficient manufacture of high-quality copper tubes directly from cathode material. The process starts with the melting of copper cathodes and in-house scrap in inductive furnaces. The liquid metal is continuously cast into shells in a multi-strand horizontal continuous caster under controlled conditions. The subsequent rapid cooling reduces the oxygen contact and minimizes surface oxidation. The cast shells are automatically cut, cleaned, and conveyed to the peeling machine for surface preparation. They are then formed in the planetary rolling mill. This unique rolling process reduces the tube’s cross-section, promotes recrystallization of the grain structure through intensive plastic deformation, and improves the material homogeneity. The rolled mother tubes are wound into coils and readied for further processing. This integrated process shortens the process chain, reduces material losses, and lowers operating and investment costs.