All over the world, our experts are working on innovative solutions and reliable technologies for the production of beams, sections, rails, and semifinished products. Already today, we are the technological leader in this field and offer a vast product range covering all aspects of rail mills, medium and heavy section mills, as well as mills to produce large bars and billets – from single machines to complete rolling lines with ready-integrated heat-treatment and finishing equipment through to expert know-how.

Thanks to our fully modularized equipment portfolio, we are in a position to offer standard solutions as well as fully customized projects for modernizations or special applications.

-

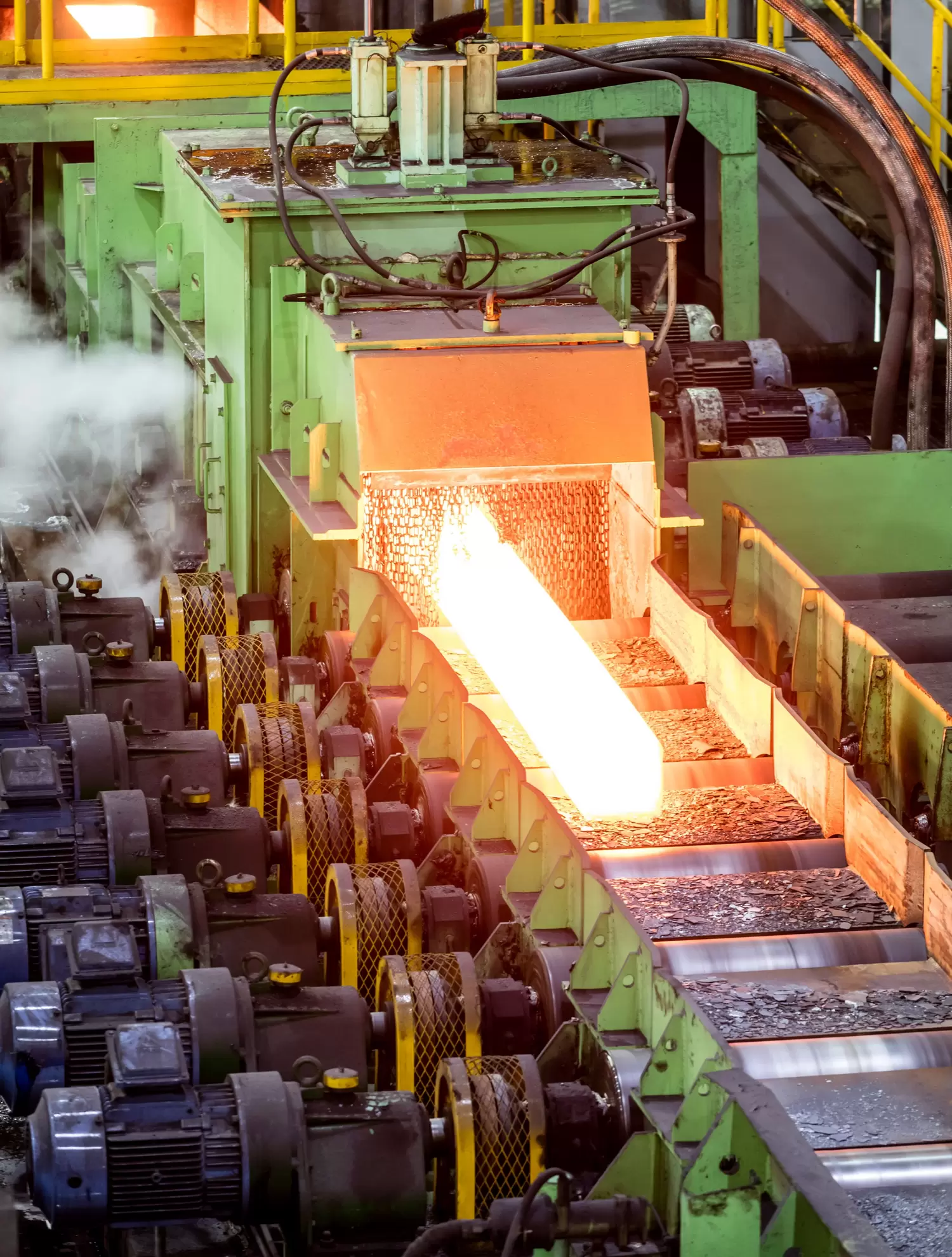

Heavy section mill

More flexibility for your product portfolio

For the production of beams as well as other larger sections, such as channels, angles, sheet piles, shipbuilding, and special sections, heavy section mills are essential. Being designed for any given size range of finished products, they allow a wide variation in the portfolio. This is of a flexibility that makes it possible to react quickly to market and customer requirements.

Heavy section mills are engineered to produce web heights measuring up to 1,200 mm.

![]()

Heavy section mill by SMS group at SULB in Bahrain -

Medium section mill

A wide range of products - Smaller products and yet diverse

Medium section mills are used for the production of smaller beams, channels, angles, flats, as well as special sections. They offer a wide range of products and can be designed as a reversing mill, a semi-continuous, or a fully continuous mill.

Medium section mills cover web heights of up to 600 mm.

-

Rail mill

Single purpose or combined for more cost efficiency

Rail mills designed as single-purpose plants can produce all kinds of rails for railways such as Vignoles, tram, crane, and special rails. As combined mills, rail mills are equipped with a section finishing end and can produce medium and large sections in line with market demands. This is where our universal rolling method comes into play. Using a tandem-reversing group it makes an important contribution to the cost-effectiveness in the production of rails as well as beams and other sections on the same compact mill.

![]()

Rails on the cooling bed at Mibao’s rail mill -

Large bar and billet mill

Increased efficiency in the production of semi-finished products

Semifinished products like blooms, billets, or large round, square, and hexagonal dimensions are produced on large bar and billet mills. As blooming mills, they are designed for the processing of billets from ingots or large continuous-cast input feedstock, whereas billet mills manufacture high-quality and stainless steel products – for example for applications in the automotive and aerospace industries. For maximum flexibility in production, semifinished products and blooms can also be produced on a single blooming mill.

Large bar and billet mills produce a size range from 40 mm up to 350 mm diameter or edge length.

![]()

Large bar mill by SMS group at Xining Special Steel Co. in China

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Compact breakdown mill

CBD mill

Compact breakdown mills form an important component when it comes to effective production in semi-continuous and reversing mills, as they create the leader passes before rolling in the finishing mill. Thanks to their compact design, engineered for maximum rigidity, CBD mill stands operate at the highest potential rolling loads. Their hydraulic cylinders and pressure transducers ensure a constant roll force measurement. To prevent breaks or damage to the adjusting system, the automatic overload protection comes with a quick roll gap opening.

![]()

Compact breakdown mill in 3-roll Precision Sizing Mill at SDI in USA Benefits

- Constant roll force measurement via hydraulic cylinders and pressure transducers

- Automatic overload protection with quick roll gap opening to avoid roll breaks or damage to the adjusting system

- High mill stand stiffness for better dimensional accuracy

- Quick roll changing