Electronic waste (WEEE), batteries, and catalysts from the "urban mine" contain significant quantities of metals such as steel, aluminum, copper, and precious elements like gold, silver, and palladium. Despite their potential value, only a fraction is formally collected and recycled, with much ending in landfills, posing environmental and health risks. SMS group’s technology, including pyro- and hydrometallurgical solutions, addresses the complex metallurgical challenges of recycling WEEE, batteries or catalysts, ensuring high recovery rates and environmental soundness.

-

Leading the charge in efficient WEEE recycling

Electronic waste or WEEE (waste of electronic and electrical equipment) is the post-consumption waste from consumer and business devices such as mobile phones, computers, screens, and household appliances. In 2022, the world generated 62 million tons of e-waste, an average of 7.8 kg per capita.

The complexity of recycling WEEE stems from the diverse and functional combination of metals and other materials, such as plastics, ceramics, and organic compounds. More than 60% of WEEE consists of various metals, including ferrous metals, aluminum, copper, PGM (platinum group metals), magnesium, silver, antimony, and rare earth elements, to name just a few. Although WEEE contains only small quantities of these metals, recycling can be highly profitable due to the high market prices for certain rare technology metals.

![]()

-

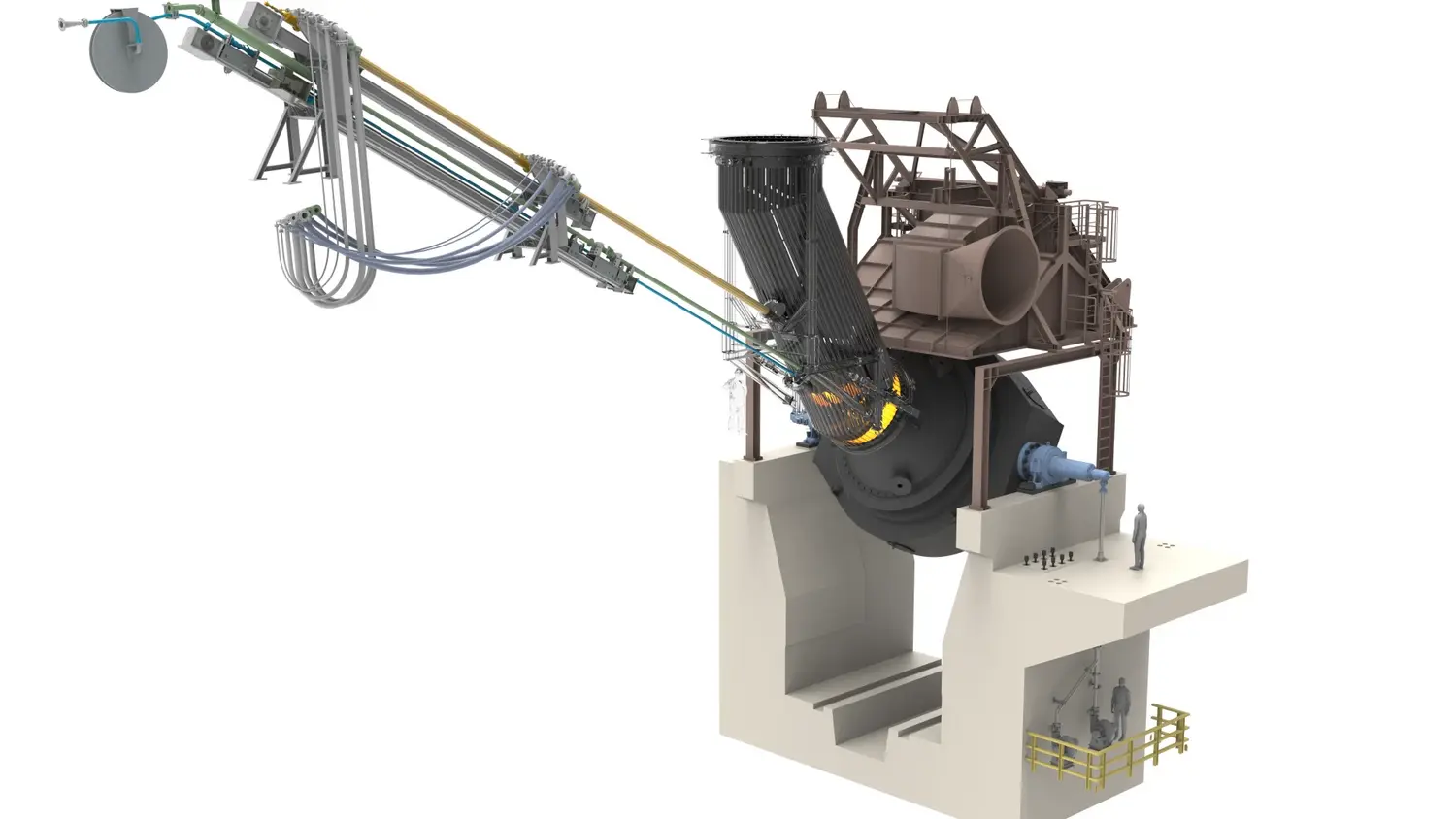

Top blown rotary converter (TBRC)

Smelting, converting and refining various raw materials with high melting and refining efficiency in one flexible unit

The TBRC combines smelting, converting and refining functions into a single, versatile reactor. An optional slag-treatment configuration further enhances metal recovery and waste minimization.

![]()

-

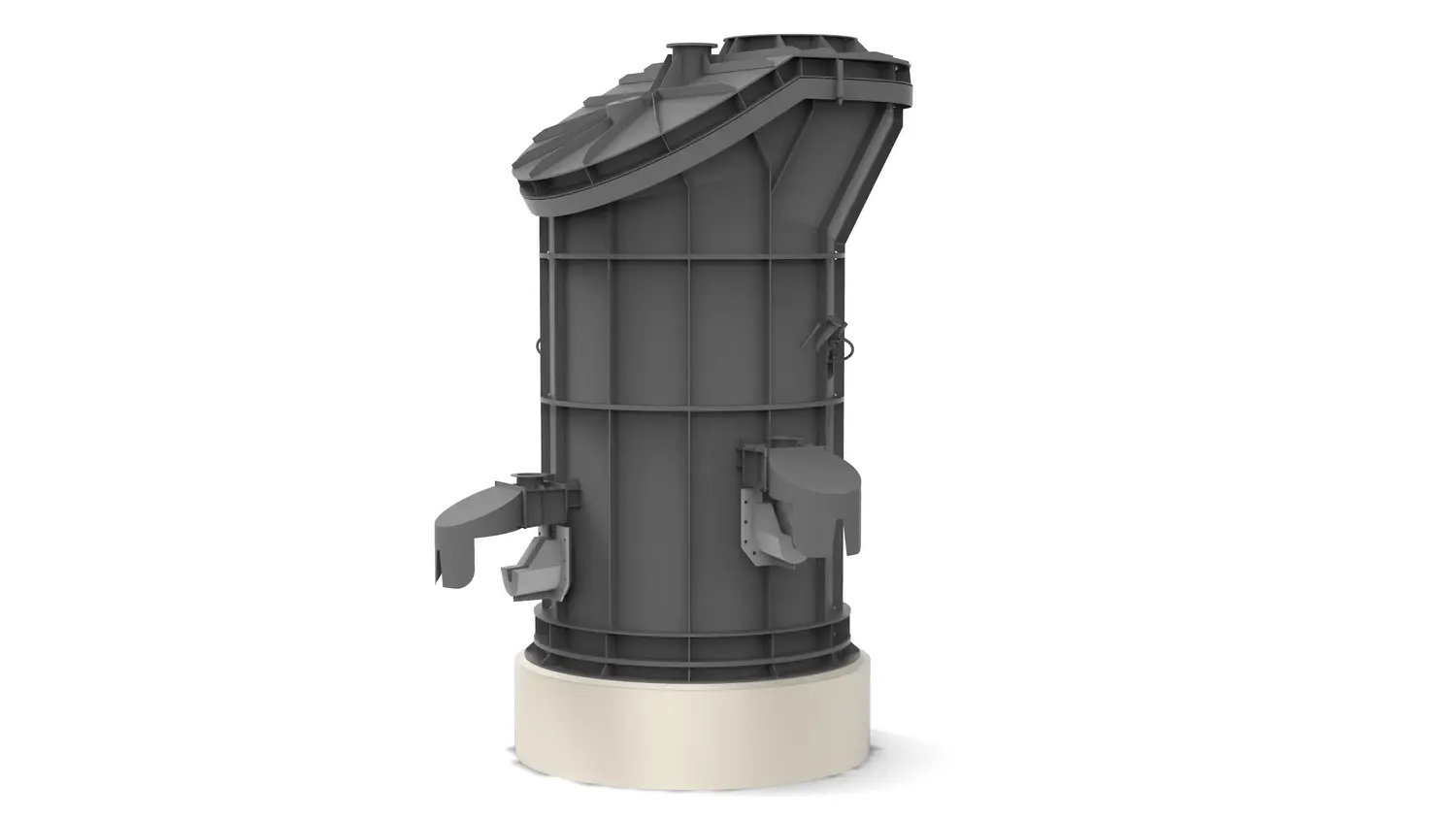

BlueSmelter

Innovative bath smelting technology

SMS group has developed its own primary smelting technology, the so-called BlueSmelter. The BlueSmelter is an innovative bath smelting technology, which processes primary raw materials for nonferrous metals production, such as copper concentrate and other ores to produce zinc, lead, tin, and other metals. The BlueSmelter was designed to process a wide range of copper and precious metals containing secondary raw materials, with a focus on low qualities and high organic content but with significant monetary value.

![]()

Benefits

- Broad feed flexibility: concentrates, oxides, slimes and organics-rich residues

- Maximized metal yield and reduced slag losses

- Proven pilot-scale performance and technical feasibility

- Simplified maintenance and lower total cost of ownership