20-high cold rolling mill

The 20-high cold rolling mill is a MonoBlock mill, type MB 22B-54“, and processes hot strip thicknesses of up to 6.2 millimeters. The compact and robust plant comes with high mill stand rigidity. Featuring a maximum rolling speed of 800 meters per minute and a maximum rolling force of 8,000 kilonewtons, it can achieve thickness reductions of up to 90 percent. Auxiliary and ancillary equipment is also included in the scope of supplies. A regenerative SUPAFINE® filter system makes sure the rolling oil is ecofriendly purified and cooled. Ecological plant operation is further supported by a fume exhaust system meeting most stringent environmental provisions of the local authorities. To reduce non-productive times, an uncoiling station, including flattener and crop shear, is integrated in addition to two reversing reels.

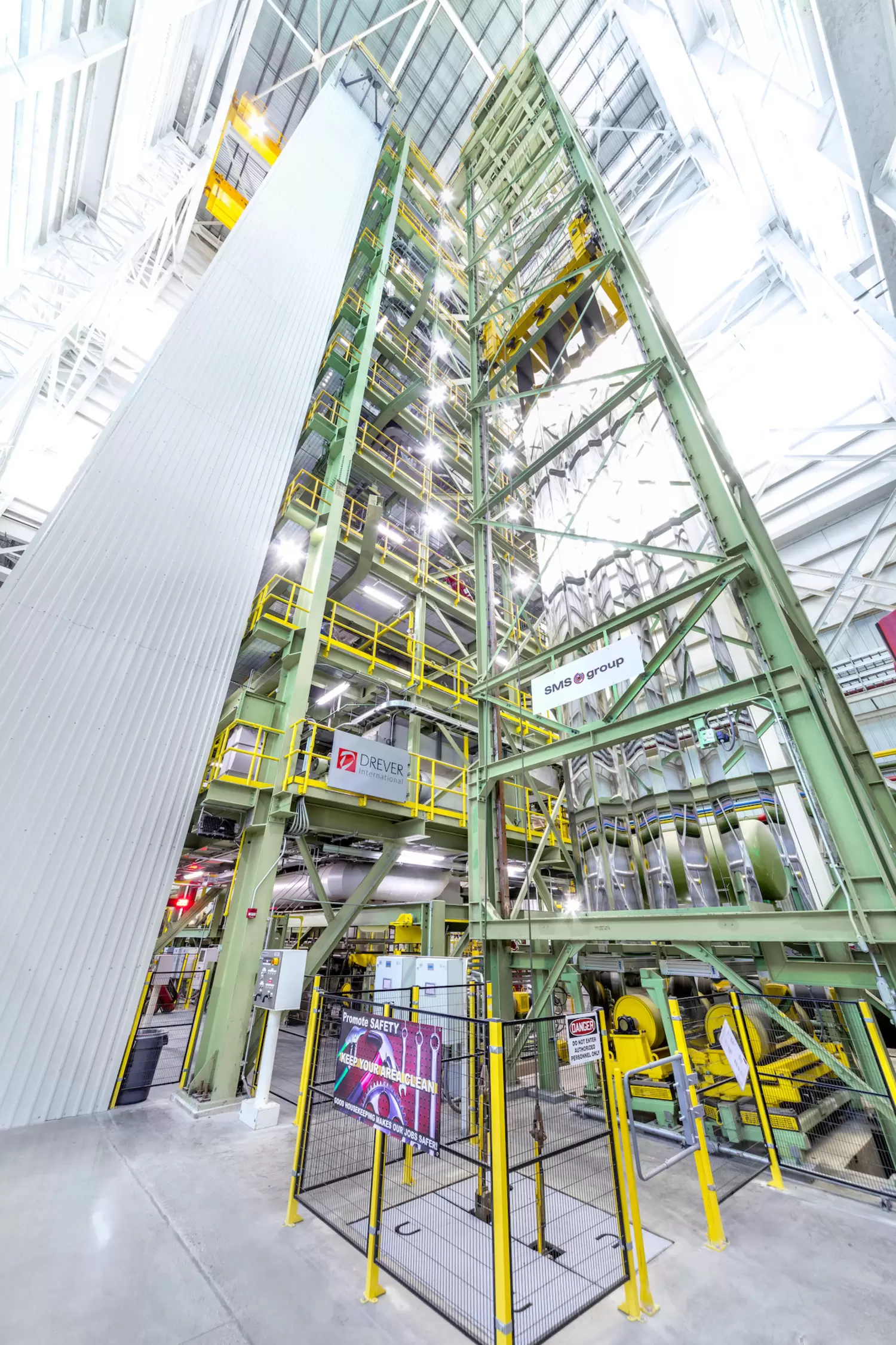

Bright-annealing line

In the bright-annealing line the strip first runs through the cleaning section. This step is followed by recrystallization annealing in an oxygen-free inert gas atmosphere with high hydrogen content, in an all-electric vertical furnace from Drever International, a company of SMS group. The annealing process is performed at a temperature of up to 1,250 degrees Celsius in an inert gas atmosphere (up to 90 percent hydrogen) under overpressure to thus generate a perfect glossy surface. The exit section of the facility is equipped with a four-high skin-pass stand and a tension leveler for strip post-treatment. A side trimmer serves for strip edge straightening and cuts the strip to the desired width.