Furnaces for the production of ferro-alloys and minerals

Electric smelters and submerged arc furnaces (SAF) are common furnaces for the production of ferro-alloys and other metals, where larger amounts of slags are processed and treated. We rely on an impressive reference base of over 1,000 electric furnaces supplied to customers in the iron, steel, ferro-alloy, chemical, TiO2, and non-ferrous metals industries. Submerged arc furnaces are ideal for smelting ore concentrate, calcine, pre-reduced ores as well as waste materials such as deposits, flue dust, slags, refractory breakout waste, and skulls. The units are highly diversified and specially developed depending on the input materials and product requirements.

Metix, a SMS group brand, operates from Johannesburg South Africa, and is a leading provider of process plant solutions and engineering services to the pyrometallurgical industry. Our expertise spans across the ferrous, non-ferrous (incl. silicones, platinum group metals, and base metals), waste recycling, slag conditioning & -valorization, as well as green iron and steel production sectors. Established in 2003 by a team of former Samancor and Bateman professionals and growing from strength-to-strength following successful projects within the early years, Metix became part of SMS group in 2011. In 2018, Metix was designated as the center of competence within SMS group for all reduction furnace applications and related business interests.

-

Ferronickel furnaces

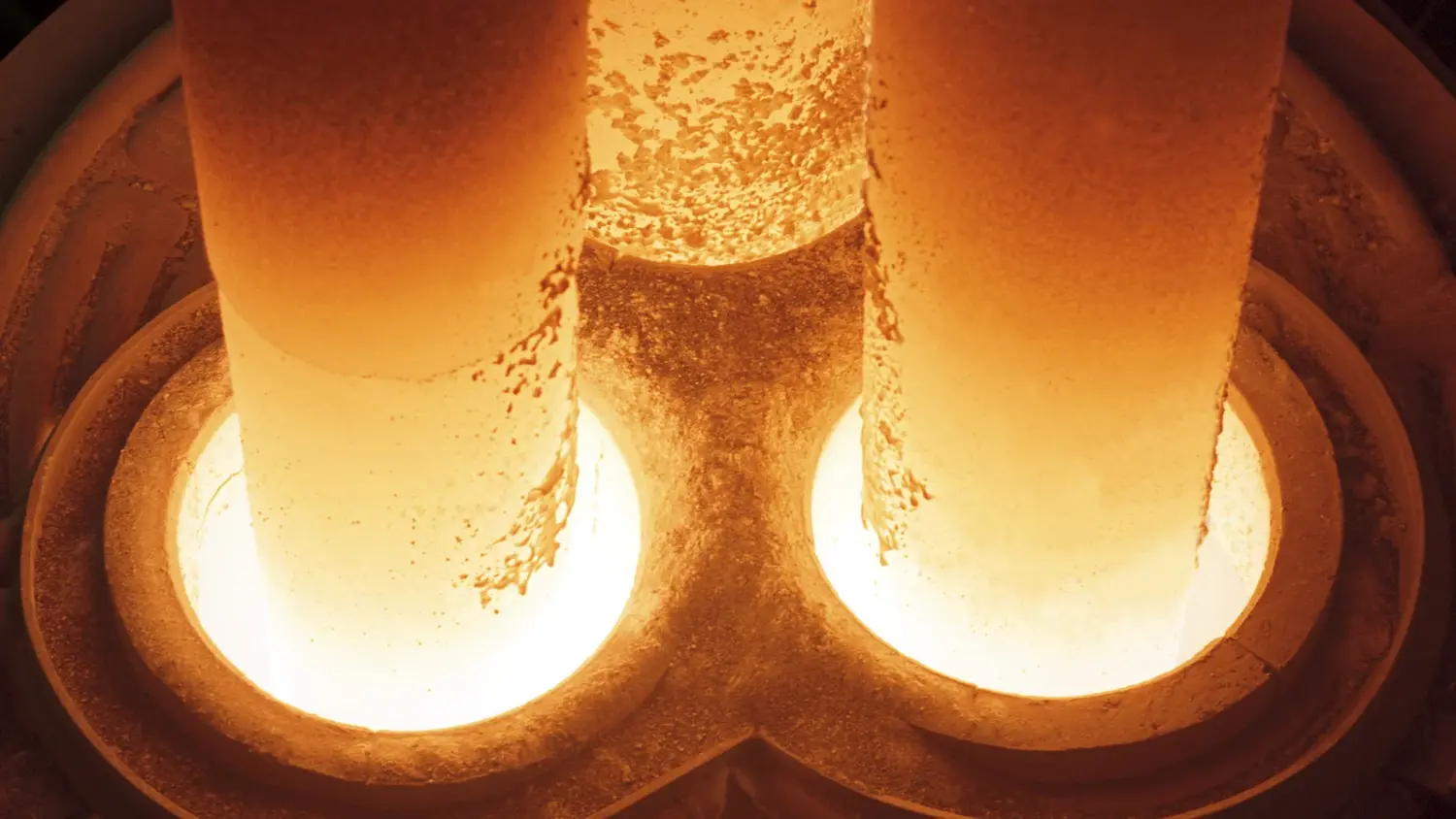

Ferronickel is mainly produced in submerged-arc furnaces by reducing nickel ores. The process aims to transfer most of the nickel into the metal phase. Attaining a high yield depends on good carbon distribution and a specific slag metallurgy. Pre-heated and pre-reduced ores are hot charged (at temperatures of up to 900 °C) into the furnace. The final nickel reduction takes place in the submerged arc furnace. Ferronickel furnaces are semi-open stationary-type furnaces. Usually, round furnaces are used for smaller and medium quantities, whereas large capacities are produced in rectangular furnaces.

![]()

-

Ferrochrome, Ferromanganese and Ferrosilicon / Silicon furnaces

High-carbon ferrochrome (4-8% C) is used in AOD converters for alloy steel production, often produced in closed furnaces due to environmental restrictions. Medium- and low-carbon FeCr require special slag metallurgy, with DC furnaces showing optimal performance. High-carbon ferromanganese (6-8% C), medium-carbon (1-4% C), and silicomanganese (15-20% Si) are produced in open/closed furnaces. SMS highlights the Sakura project in Malaysia, delivering a turnkey FeMn/SiMn plant with two 81 MVA furnaces, achieving above nominal capacity. Ferrosilicon grades (15-96% Si) are produced in submerged arc furnaces, with >96% Si grades known as silicon. SMS furnaces excel in durability and efficiency, with some operating for over 50 years.

![]()

-

Titanium slag furnaces

These furnaces produce TiO2-rich slag and pig iron as valuable byproducts. The ilmenite ore can be processed in either DC or AC furnaces. The advantage of DC furnaces is that they can smelt ore fines without any particular pre-treatment. Normally, the specific electrical power consumption is higher due to the lower thermal efficiency of the furnace. Most smelters in South Africa are DC-based. TiO2-slag can also be produced in AC-based smelting units, either in circular or rectangular furnaces.

![]()

-

Calcium carbide furnaces

Calcium carbide (CaC2) is the raw material for the production of acetylene and calcium cyanimide. Initially, acetylene was produced for lighting purposes, then its market was extended through welding acetylene to the manufacture of organic products. In organic and plastics chemistry, calcium carbide competes with various processes for the production of acetylene from hydrocarbons. Today, calcium carbide is mainly used in the chemical industry and as a desulfurization agent in steel production.

![]()

-

Minerals

What defines the SAF principle is that it melts minerals at high fusion temperatures. This is why our furnaces are also applied in various fields for refractory and mineral production. SAFs are ideal for producing the following products:

- Corundum (Al2O3)

- Fused magnesia

- Fused minerals

- Mineral and slag wool

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

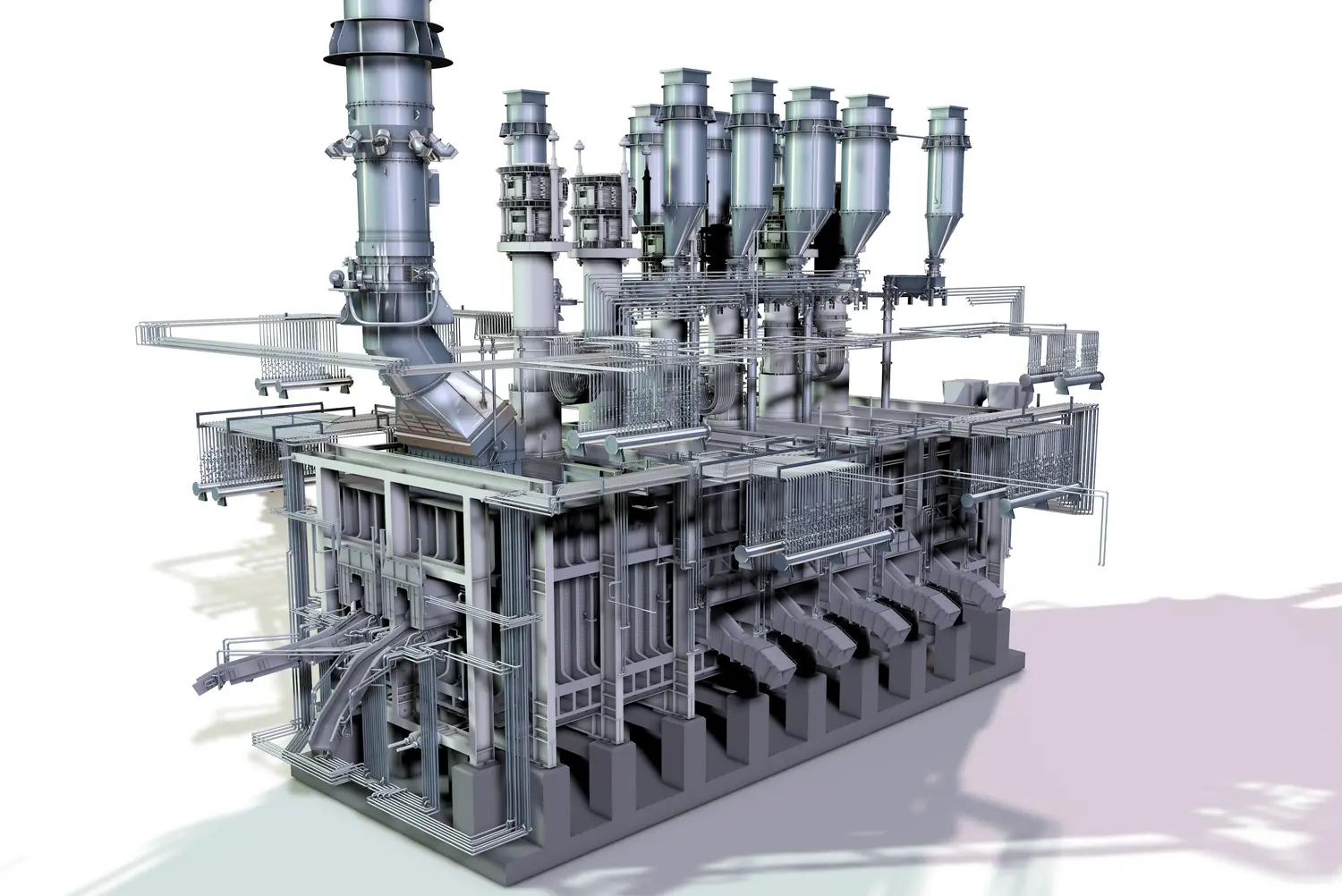

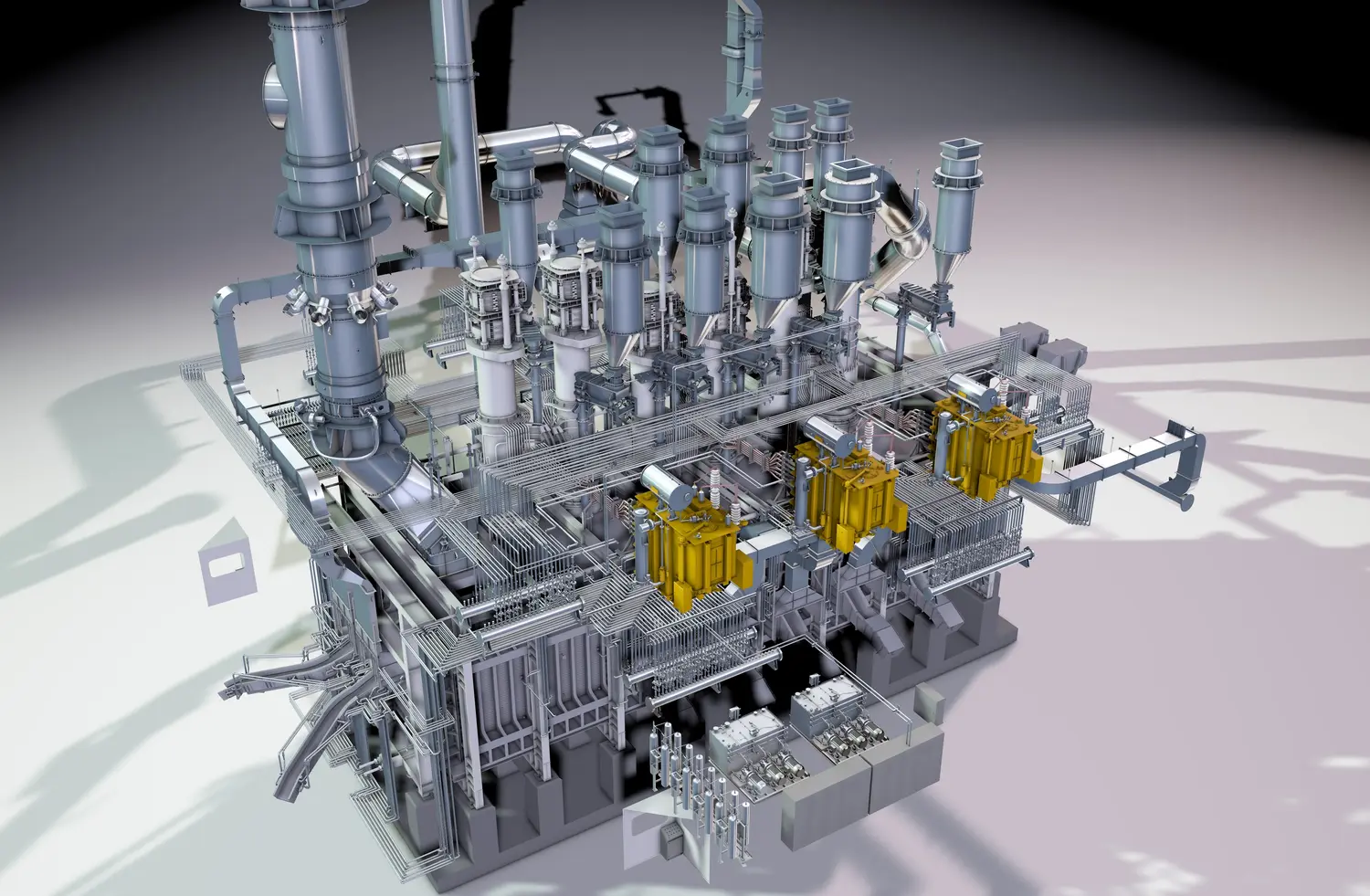

Large capacity rectangular AC furnaces

Rectangular furnaces are versatile vessels that can be applied to a wide variety of applications within the ferrous and non-ferrous industries. They are also utilized in slag cleaning where extensive settling times are required as well as slag valorization where large amounts of slag need to be conditioned.

![]()

-

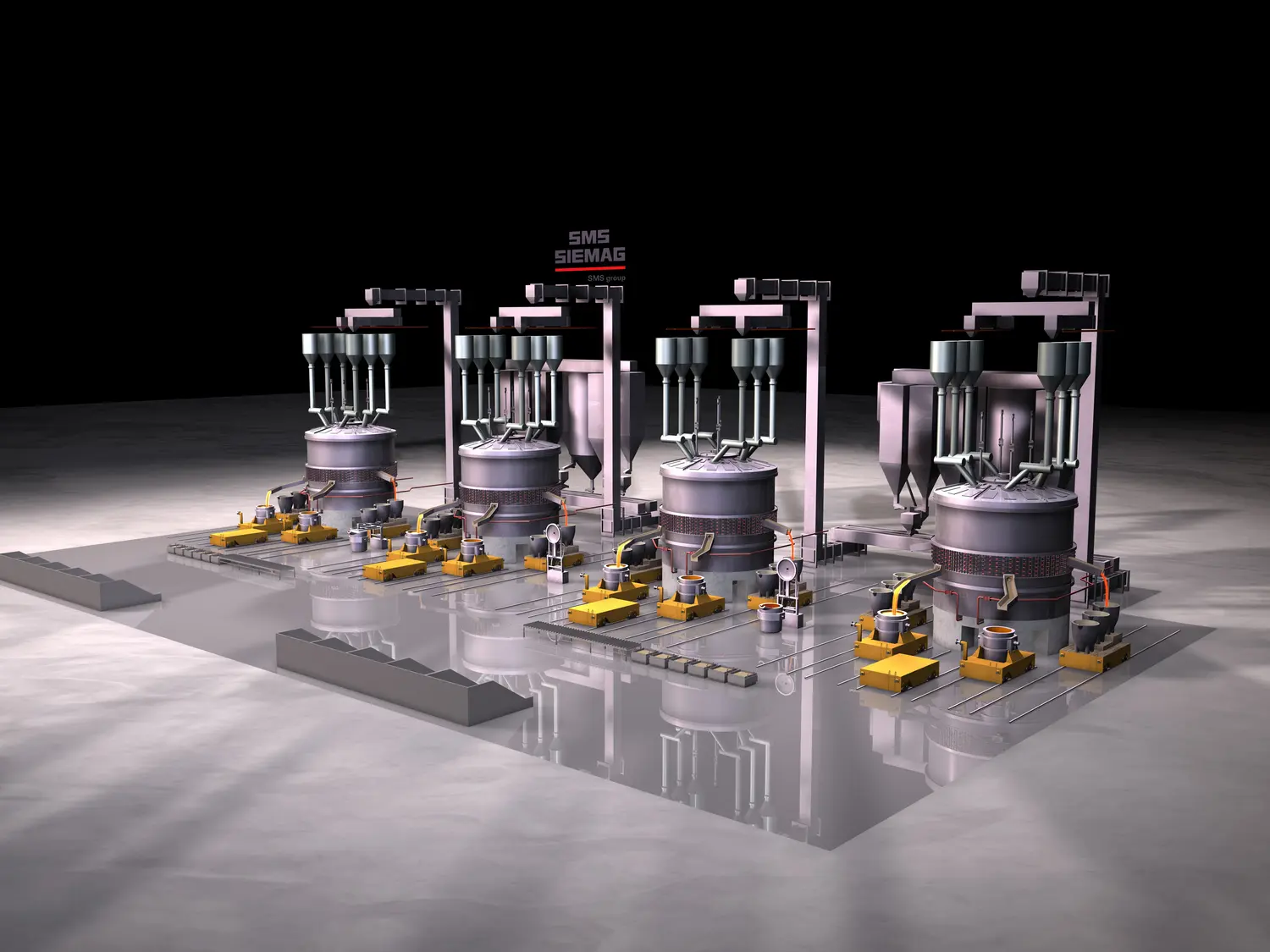

Large-capacity circular AC furnaces

Circular AC furnaces are used extensively to smelt a range of ferro alloy products including but not limited to FeCr, FeMn, SiMn, FeSi and FeNb. Applications in the non-ferrous industry include commodi-ties such as PGM’s, CaC₂, and mineral wool.

-

DC furnaces for TiO₂ slag and FeCr production

A DC furnace utilizes a DC rectiformer to supply power to the furnace crucible. The configuration is typically a single graphite electrode which acts as a cathode, whilst the anode is embedded in the furnace hearth. The energy is supplied through an open plasma arc that forms between the electrode tip and furnace bath. DC furnaces are well suited to smelt fine raw materials and are used in the TiO₂ slag and FeCr industries. Applications for other commodities are also possible where processing of fine raw materials are required.

![]()

-

Semi-closed rotating AC furnaces for MgSi and FeSi production

Semi-closed rotating AC furnaces are mainly used for MgSi (manganesesilicon) production but can also be applied to FeSi (ferrosilicon) processes.

![]()

-

Advanced refining solutions for ferroalloys

SMS group offers advanced refining technologies for ferroalloys, with significant expertise in FeNi refining through ladle furnace solutions and auxiliary equipment. Additionally, SMS group's cutting-edge converter technology, including conventional BOF and AOD converters, employs fluid flow optimization and innovative CO2-blowing techniques to enhance FeCr and FeMn refining, achieving high chromium yields and reduced operational costs.

![]()

Services for your plant

Sorry, there are no results for the search term.