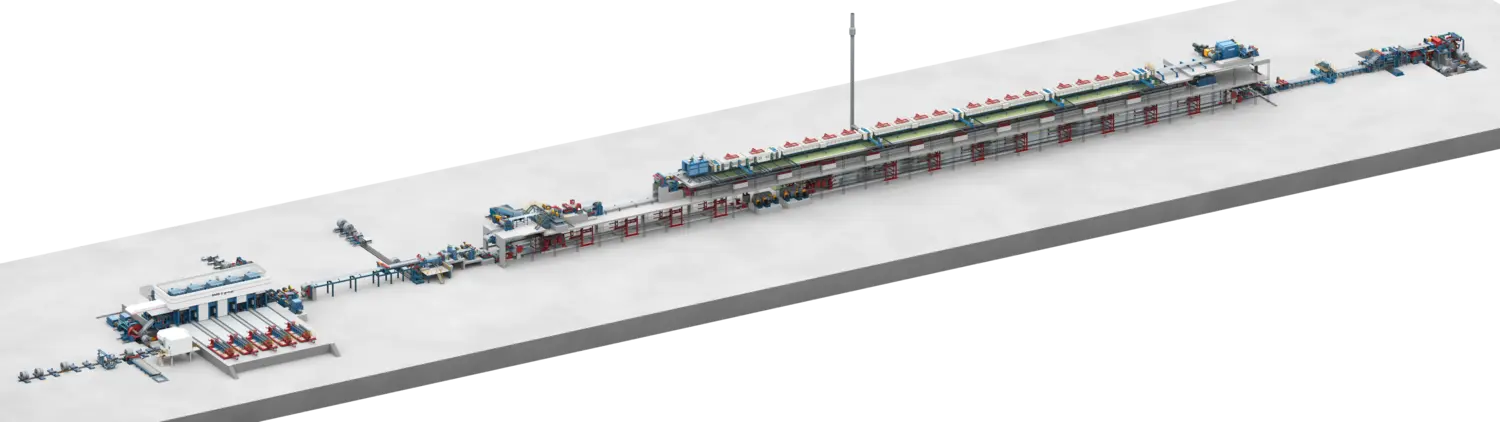

Habaş A.S., located near Izmir, Turkey, continues its stride towards modernization and expansion. Following the project start of the pickling line/tandem cold mill (PLTCM) in October 2021, Habaş progressed with the next phase of their partnership with SMS group in April 2023 when the second part of the contract package came into force and marking another significant milestone in their longstanding collaboration. With the new facilities, Habaş intends to expand its manufacturing capabilities in cold strip production considerably and strengthens its own market position. The pickling-line/tandem cold mill (PLTCM) will already reach the installation phase by August 2025. In order to optimize the cold strip properties and product qualities, Habaş has ordered from SMS group an offline skin-pass mill, two continuous galvanizing lines (CGL1 and CGL2), a recoiling and inspection line (RCL) and a tension leveling line. This enables Habaş to produce a large spectrum of advanced steel grades, including, for example, deep drawing material and high-strength grades.

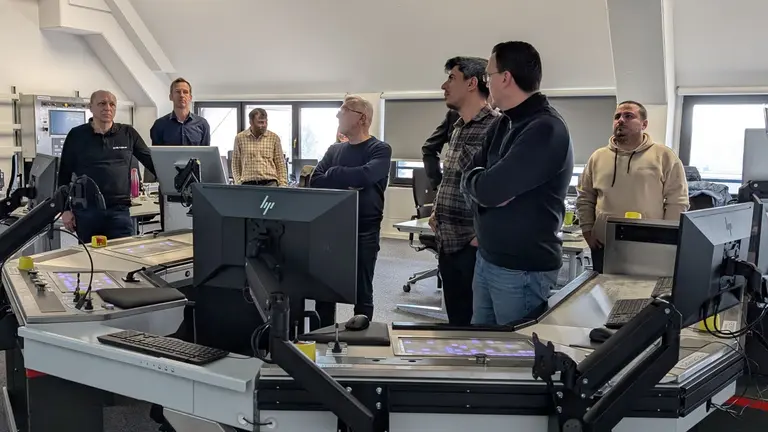

Digital commissioning of automation with X-Pact® Plug & Work integration test

In order to perform the X-Pact® Plug & Work integration test for Habaş, SMS group set up the entire automation system for the customer-specific plants in its test field in Mönchengladbach, Germany and connected it to the plant and production simulation. The digital twin of the integrated plant, developed in parallel with the engineering process, was brought to life during the Plug & Work test by integrating simulation data. The digital twin is subsequently further enriched with online data from the real plant in order to increase its value.

Haşim Ayten, Plant Manager at Habaş, emphasizes the importance of this step:

"The Plug and Work integration test provided us with an invaluable opportunity to ensure all automation systems functioned seamlessly before installation. The realistic simulations and thorough testing allow us to confidently proceed with the commissioning, knowing that our systems are optimized for efficiency and reliability."

With the X-Pact® Plug & Work test, the original hardware and the software for the customer-specific plants are tested, pre-optimized in the test fields as a complex unit. This saves Habaş valuable time and enables faster ramp-up, very high product quality from the beginning and a ready-made stable production environment.

Plant technology

Pickling line / tandem cold mill (PLTCM)

The five-stand pickling line/tandem cold mill is expected to be installed by August 2025. Equipped with SMS group's latest turbulence pickling technology and a scale breaker, the line ensures an annual cold strip production capacity of 1.65 million tons. The tandem cold mill, featuring CVC® plus technology and an enhanced shifting system, guarantees excellent cold strip tolerances and flatness. With the capability to handle strips as thin as 0.20 millimeters and widths ranging from 700 to 1,980 millimeters, it offers flexibility in production. The carousel reel features the new revolving reel mandrel support bearing, ensuring safe winding of rolled cold strips, even for high-strength grades, which require coiling under high strip tension. The PLTCM allows for flexible production processes and can operate in fully continuous or batch mode.

Offline skin pass mill

The offline skin pass mill (SPM) is designed to process hot and cold rolled coils to meet market demands. With an annual capacity of 0.65 million tons, it offers flexibility to handle various coil types, including cold rolled, annealed, hot rolled, and pickled coils. Depending on the incoming material, the skin pass mill can process strips with widths ranging from 965 to 2,100 millimeters and thicknesses between 0.25 and 4.0 millimeters. As the main task of skin passing is to elongate the strip, the maximum value to be achieved is 1.2 percent.

The skin pass millis designed as a four-high mill, featuring work roll shifting and bending to achieve the required strip properties. Equipped with a wet skin-passing system, it ensures strip elongation while maintaining moisture control through the exit-side blow-off dry strip system (DS system), ensuring the strip being coiled on the tension reel is as dry as possible.

The skin pass millis fully equipped with entry and exit side equipment, as well as auxiliary and ancillary systems, to ensure reliable and efficient operation.

Continuous galvanizing lines

The continuous galvanizing lines (CGL1 and CGL2) are integral parts of Habaş's new facilities supplied by SMS group. Continuous galvanizing line 2 features a horizontal Drever furnace, with horizontal entry and exit accumulators. It is designed for an annual production of 440,000 tons, primarily for construction grades. The strip thickness ranges from 0.25 to 2.5 millimeters (cold rolled) and 1.20 to 4.0 millimeters (hot rolled), with a maximum width of 1,930 millimeters. Post-treatment includes a four-high skin pass mill a tension leveler, and a horizontal roll coater.

CGL1 operates with cold-rolled material from the SMS PLTCM and is designed as a modern automotive line with a vertical Drever furnace, vertical loopers, fully-equipped cleaning section, inline SPM tension leveler, spray passivation system, and side trimmer. It has an annual production capacity of 400,000 tons.

Both continuous galvanizing lines are equipped with IAS pot systems and Duma-Bandzink air-knives, bath equipment and oiling machines. SMS group underlines in this project its capabilities as full system supplier for strip processing lines.

As with the pickling line, the continuous galvanizing lines features the modularized software architecture of the X-Pact® automation system from SMS group supported by the state-of-the-art automation hardware platform Siemens S7. The SMS X-Pact® automation system is utilized for control and monitoring, providing advanced functionalities tailored to the processing lines' needs.

The basic X-Pact® automation system comprises the terminal equipment, process equipment, as well as the furnace automation with furnace model. Furthermore, all processing lines have the X-Pact® Level 2 solution, the flexibly selectable database, and the latest interfaces for connection to higher-level planning and data analysis systems.

Additionally, the modular drive solution X-Pact® Drive ensures maximum process-oriented drive performance, enhancing energy efficiency and optimizing lifetime costs.

Recoiling and tension leveling line

As part of the cold mill complex, the recoiling and inspection line (RCL) is designed to process cold-rolled annealed or galvanized material from upstream CGLs and the offline skin pass mill. This line encompasses functions like welding, tension leveling, inspection, defect marking, edge trimming, center cutting, oiling, and coil dividing. It will enhance Habaş's flexibility in serving its end-users with a wider range of products. Incoming strip thickness ranges from 0.25 to 2.5 millimeters, with a strip width of 700 to 1,930 millimeters. Operating at a maximum line speed of 300 meters per minute, the RCL has a yearly capacity of 300,000 tons.

X-Pact® electrics and automation: High quality and productivity thanks to integrated solutions

The proven solutions in the field of electrics and automation are brought together under the X-Pact® (process, automation, control, technology) trademark. A holistic X-Pact® package comprising basic and process automation systems is a crucial success factor in the realization of this complex project. This is where everything comes together to control, monitor, test, evaluate, optimize and coordinate the system.

The innovative X-Pact® Vision HMI concept, with its forward-looking interactions, structures and communication channels within the plant automation, ensures safe operator guidance and offers comprehensive tools for system maintenance, diagnostics, and troubleshooting.

X-Pact® electrical and automation systems are opening up new competitive opportunities for Habaş by implementing customized modernization strategies, especially when it comes to digitalization, plant reliability, and product quality, and they provide a solid foundation for future-oriented extensions and applications.

With each milestone achieved, SMS group reaffirms its commitment to technical excellence and collaborative success, both in partnership with its customers and within the steel industry. Leveraging SMS group's expertise and integrated solutions, Habaş is well positioned to enhance its manufacturing capabilities and establish new benchmarks in the steel industry.

Peter Waldhoff, Executive Project Director at SMS group, highlights the collaborative approach: "Through my experience, I have learned that the success of any project hinges on the ability to foster confidence, identification, and acceptance among maintenance staff and operators. By prioritizing social skills and relationship-building between commissioning engineers, maintenance staff, and operators during X-Pact® Plug & Work integration test, we lay the foundation for effective team-building and project success."

Haşim Ayten, Plant Manager at Habaş, reflects on the partnership: “I strongly believe that SMS group's method for integration testing of automation brings significant advancements in ensuring safety and quality during the plant erection and commissioning process. By involving our team from the very beginning, SMS has effectively prepared us for the upcoming tasks to optimize the startup phase and enables us to utilize the new equipment efficiently within a short time. The training was a valuable opportunity for the Habaş team to work and learn together, resulting in a skilled and confident workforce, as well as meeting the SMS team to even deepen the good relationship. We approach the commissioning phase with great confidence and optimism.”

I strongly believe that SMS group's method for integration testing of automation brings significant advancements in ensuring safety and quality during the plant erection and commissioning process.