Cost drivers can be found right along the whole value chain in every steel plant – and that includes Maghreb Steel. With an annual production capacity of around one million tons of steel, Maghreb Steel is the leading manufacturer of high-quality flat steel products in Morocco. In the production facilities in “Tit Mellil” and “Bled Solb”, these cost drivers were identified during a fact finding mission by SMS digital and will now be eliminated as part of a digitalization offensive. The aim here is to exploit the full potential of digitalization and manufacture cost-efficient, high-quality products with minimal energy input. \"Maghreb has recognized the potential of digitalization and is making profitable use of it. We firmly believe that Maghreb will achieve enormous success by integrating digital solutions,\" says Bastian König, Project Manager at SMS digital. As a result, concrete improvement measures in the areas of predictive production, planning, quality, plant condition, energy, IT infrastructure, operative controlling and logistics were identified and are now being jointly implemented by both partners. The focus here is on Maghreb's steel making plant, the hot rolling mill, and the cold rolling mill.

Optimized process design through digital solutions

The use of digital solutions is intended above all to enable Maghreb to achieve even more solid planning reliability and a more transparent overview of cost factors and potential savings. The following areas for action were singled out in particular: Smart maintenance strategies enable the stabilization of production processes, and a higher degree of automation means greater efficiency and data generation. The integration of relevant data sources into an overarching production data warehouse provides for efficient and extended analyses and serves as a basis for digital applications. Automated tests, quality tools, and documentation meet the high quality requirements of the automotive industry and ensure more efficient and consistent product quality. Last but not least, digital solutions enable optimized and stabilized demand and sales planning when it comes to raw materials and customer orders.

Smart quality and alarm management

The identified areas have highlighted specific points of reference. For example, SMS digital's Metallics Optimizer can be employed to reduce raw material costs. The application forecasts the proportion of copper concentration and unwanted tramp elements in the scrap by means of artificial intelligence (AI) before it is melted, and calculates the most favorable composition for the melt feedstock. As an intelligent alarm management system, Smart Alarm can better detect relevant alarms in the Steckel mill. By providing automated notifications and intelligent analyses, this application enables faults and malfunctions to be eliminated faster, thus considerably reducing production costs and downtimes.

Predictive energy management

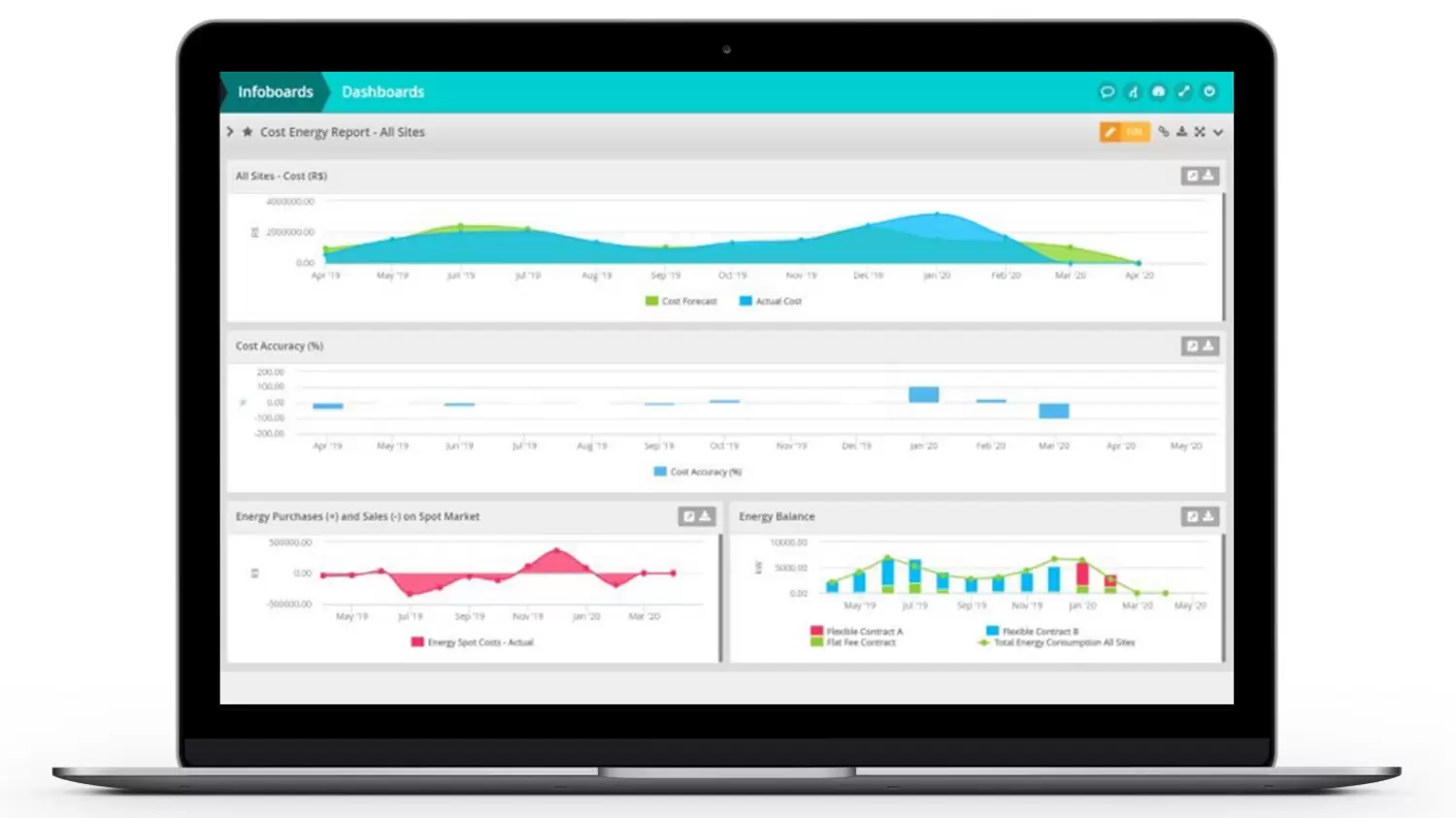

Another important aspect is to reduce raw material costs and thus save energy. By using digital energy management solutions, Maghreb has a clear overview of its energy consumption and can manage it in a targeted way by means of golden batch analyses. In particular, unscheduled downtimes and asynchronous production processes generate high energy-consumption levels. Here, too, SMS digital has the right digital solution with its Viridis Energy and Sustainability Platform, which enables production processes to be designed as sustainable and cost-effective as possible. Self-improving AI models can predict the process behavior and define energy and resource efficiency targets that take the conditions and operation of the plant into account.

Digitalization as a success factor

By choosing SMS digital, Maghreb Steel has a partner with a technological edge in digitalization and solid expertise in applied research and in the assessment of existing methods and the market: "We see SMS digital as the right partner for our digital transformation process and look forward to the successful implementation of the first joint pilot projects this year," says Youssef Baidou, Director of IT and Digitalization at Maghreb. The first concrete pilot projects for scrap charging and smart alarm systems are in the detailing phase and will now be implemented gradually.

The huge increase in flexibility and efficiency are major advantages that come from linking digital solutions to a plant or machine. Not just in terms of production planning, which with the right digital solutions also takes spontaneous order planning changes into account and enables intelligent process configurations, but also in terms of the investment required: With software-as-a-service models, for example, digitalization enables CAPEX to be converted into OPEX and keeps the required level of investment as low as possible. With its range of digital solutions, SMS digital enables plant owners to make decisions based on specific data and information, no matter how complex these may be. This means they can be proactive and respond appropriately to spontaneous events. The efficiency and profitability of entire plant complexes is ensured along the entire value chain. Together, SMS group and SMS digital provide companies with the plant and machinery, the electrical and automation systems, and the digital products to secure the production of green steel.