Performance-enhancing design and maintenance services

To help steel and aluminum producers achieve their quality goals, SMS group expertly reconditions, maintains and retrofits chocks, reels and mandrels for hot, cold and temper mills to the exacting tolerances demanded by today’s sheet and plate producers. We also build new mandrels and supply spare components for hot and cold mill applications.

SMS group has the experience, expertise and expert craftsmanship needed to build reliable new mandrels and keep reconditioned reels and mandrels running at top efficiency. As proof, units we have built or reconditioned continue to set production and quality records for our customers nationwide.

We achieve these substantial performance enhancements by working in close partnership with our customers, proactively looking for ways to improve the life of the part, identifying performance issues and making recommendations for improvements to design, materials and/or lubrication that will extend equipment service life and production campaigns. Because our maintenance enhancements can produce as much as a five-fold increase in campaign life or production tonnage, they can deliver outstanding returns on maintenance investments.

Diligent attention to tight tolerances, precision machining and assembly work help ensure that our units consistently achieve top performance and meet or exceed the exacting tolerances demanded by today’s automotive, appliance, and similar markets. Precise adjustments made in our shop help insure superior performance in your operations.

Customer-driven field services

Working out of our numerous field service centers, our experienced technicians conduct a detailed analysis of your operating and maintenance conditions and develop materials and lubrication recommendations to improve performance and product quality, maximize yields, extend equipment life and reduce downtime. We also provide field assistance and on-site mutual tracking; technical advice and assistance; and performance evaluations and recommendations for upgrades and enhancement to keep your equipment operating competitively. As a result of our field service evaluations and recommendations, record runs have been reported on mandrels we have reconditioned.

Additional services

To further enhance our reconditioning and field services, SMS group also provides value-added services designed to help you keep your mandrels operating flawlessly over longer in-service periods. These services include maintaining inventories of crucial components to minimize downtime; cost-per-ton agreements that guarantee uptime and efficiency; and on-site assistance. To learn more about how SMS group’s performance-driven coiling and rolling mill services can help you produce superior products and maximize yields, give us a call at +1-412-231-1200.

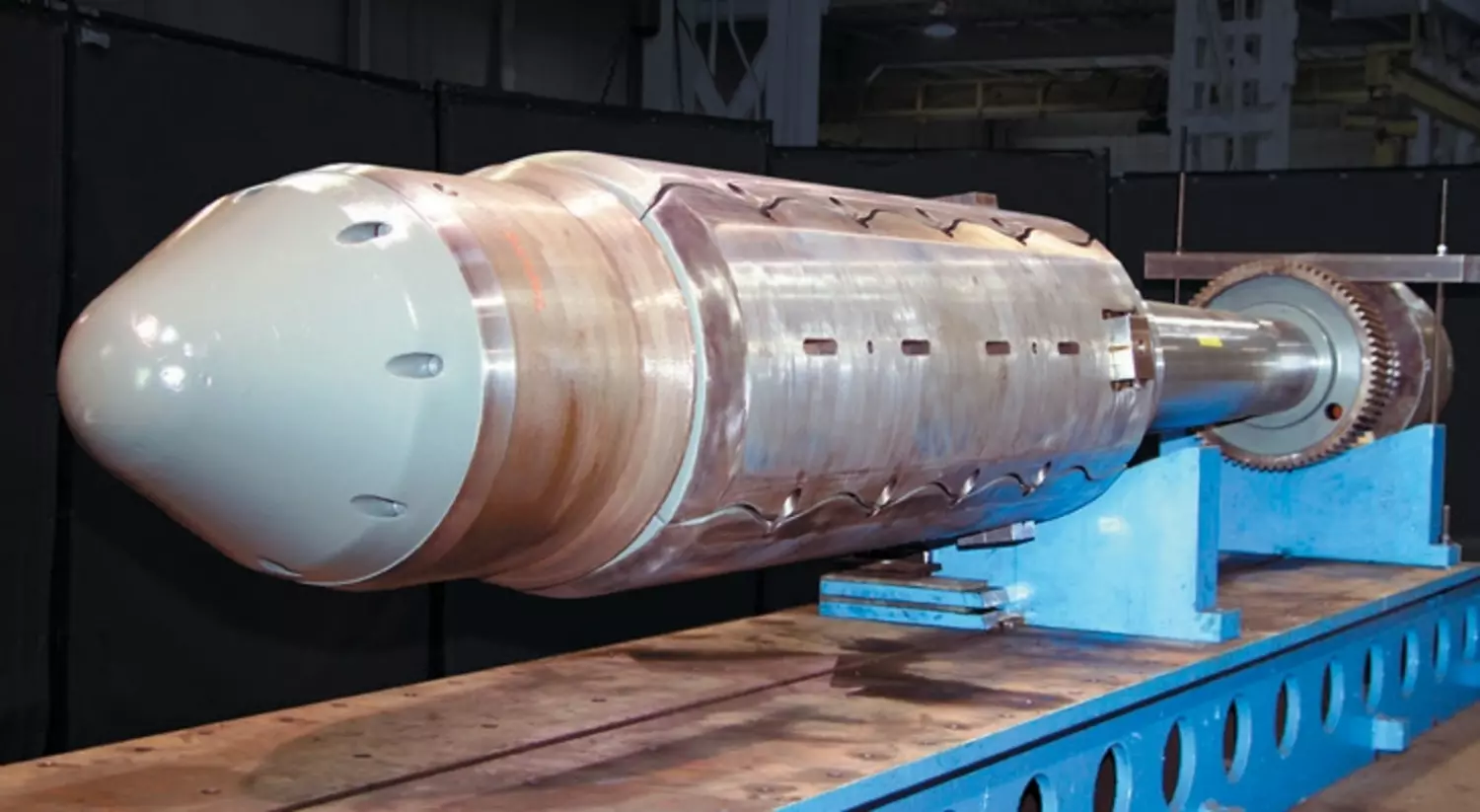

Expertly reconditioned mandrel

Maintenance enhancements can increase mandrel campaign life

Tension reel, downsized to accept a urethane boot, set production records