When field inspection reveals unexpected gear wear or damage that could have occurred in conjunction with catastrophic bearing or gear failure in your hot or cold rolling mill drivetrain, SMS group can expertly rebuild, repair or upgrade the gear box or pinion stand off-line.

As one of the largest off-line maintenance suppliers in the US, we provide expert service for most OEM manufacturers’ pinion stands, small-to-medium mill drive gear boxes and ancillary components, like bearings and shafts, from large gear boxes. We also provide gear and gear teeth diagnostics and inspections and can set and verify gear contact patterns and backlash.

Powerful partnership

Throughout our repair process, we work closely with engineers at our parent company, SMS group, to ensure repairs meet OEM tolerances and standards. As a global supplier of rolling mill drivetrain equipment, SMS group’s operations, technical, engineering and manufacturing expertise enhance and complement our extensive equipment maintenance knowledge and experience

First, thorough inspection

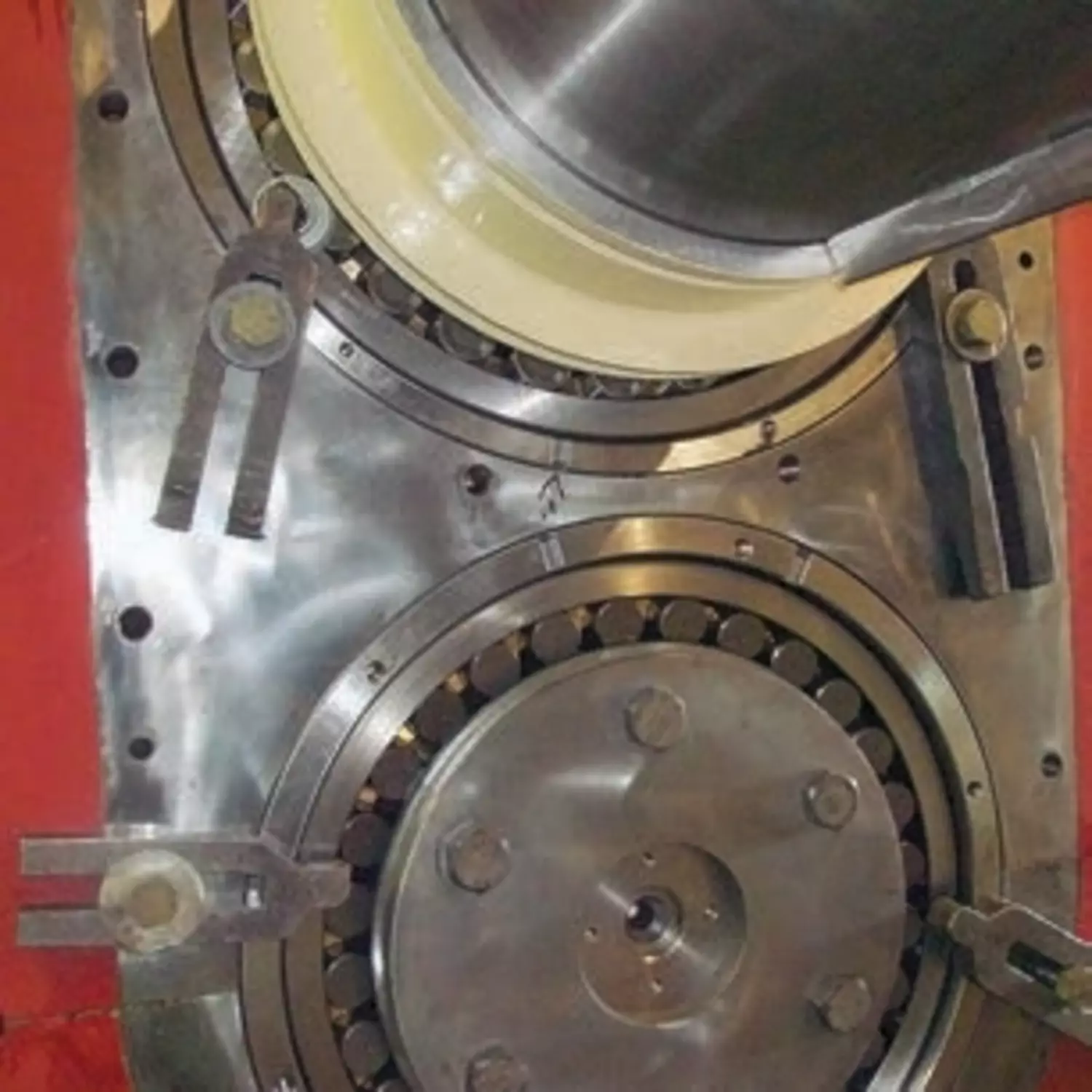

Gear box and pinion stand rebuilds begin with a thorough diagnostic inspection. After opening the inspection covers, we thoroughly check and document tooth condition, backlash and contact patterns. The unit is then disassembled and gear assemblies are removed and inspected using non-destructive testing (NDT) methods, then completely disassembled.

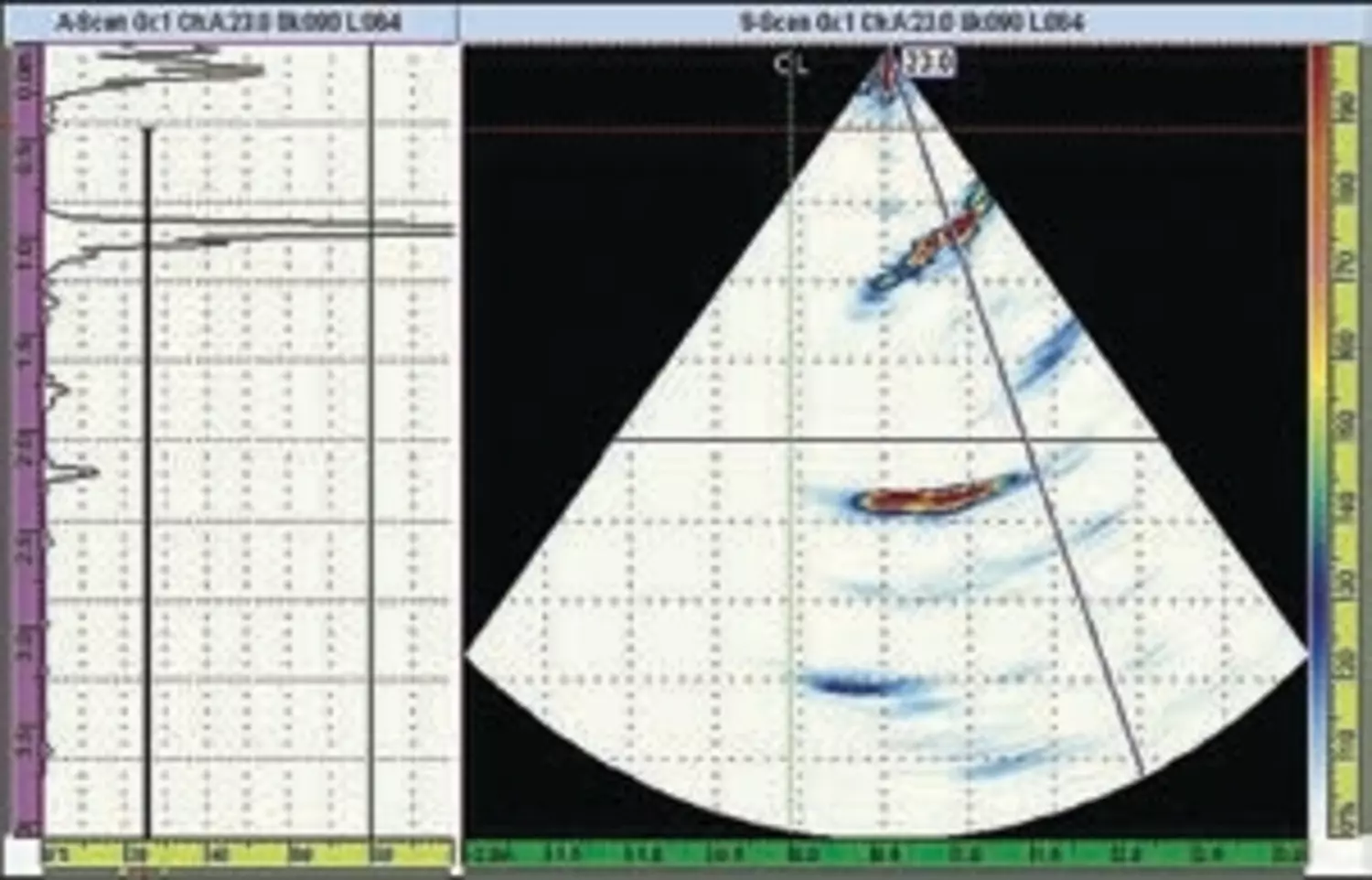

After we visually inspect the bearings, they are typically sent to your designated bearing-reclaim facility for additional detailed inspection and repair if needed. We also check gear teeth for cracks or damage using ultrasonic and other NDT methods. Last, we partially assemble the unit, carefully inspect bore dimensions and check bore alignment. All weld joints are also inspected for cracks, and ancillary parts are visually and dimensionally inspected.

Components from large gear boxes, such as bearings, bearing cartridges, shafts and eccentric bushings, also receive a thorough, documented inspection before repairs begin.

The result of our inspection is a detailed report on the condition of your drivetrain unit or component including all of the inspection and test results and parts photos.

Informed rebuild scope

After our inspection is completed, we meet with you to discuss the results and any operational issues we may have observed during inspection. Working together, we develop a scope of repair and delivery schedule tailored to your needs.

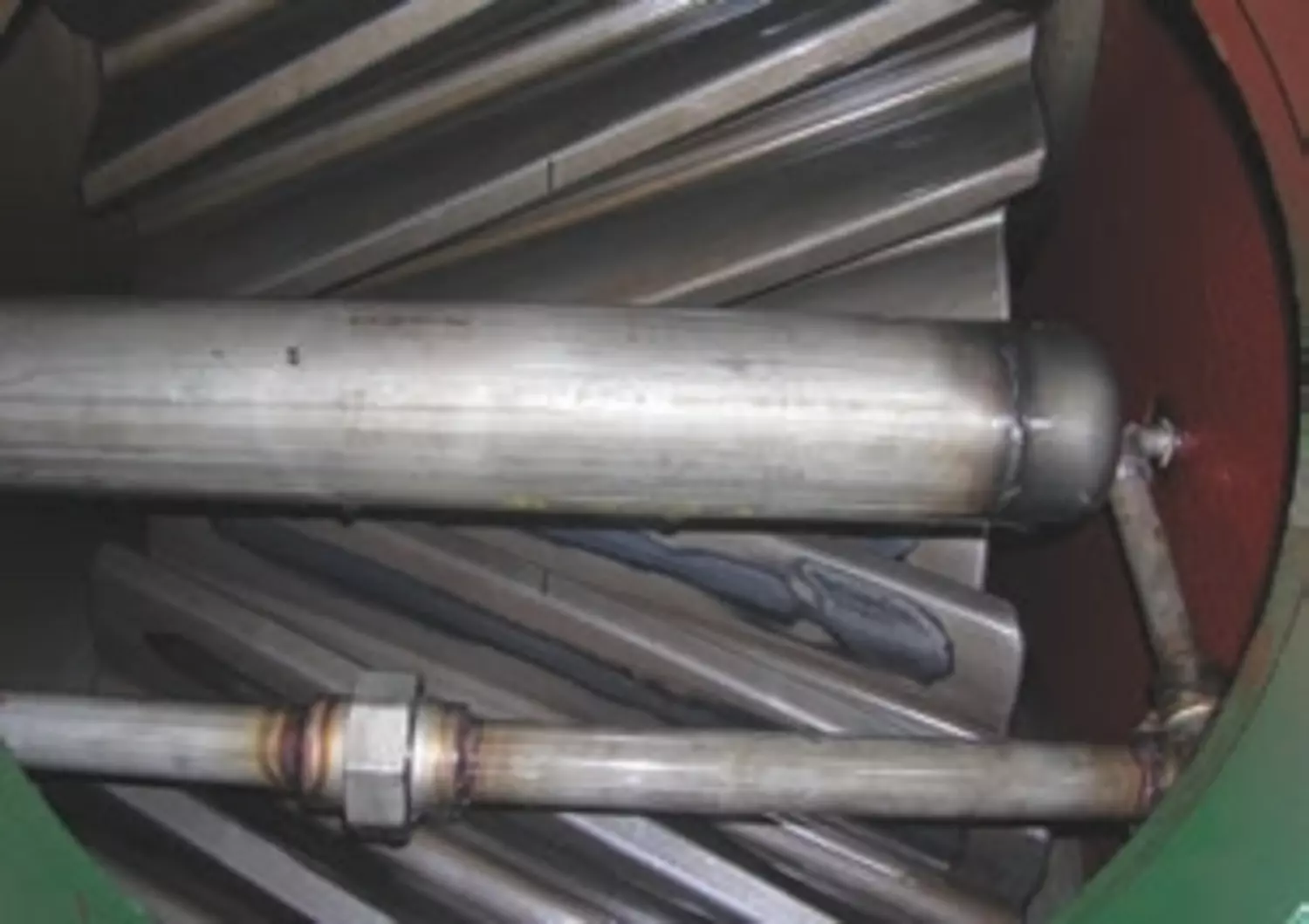

Extremely poor contact pattern created high temperatures and vibration

Ultrasonic inspection of gears can reveal hidden damage

Knowledgeable repairs

Depending on your requirements, we reassemble new or reused gears using new, refurbished or used bearings, eccentric or standard sleeves, ancillary parts and drive/spindle couplings. Gear assemblies are then reinstalled into the unit, and the tooth contact pattern and backlash are carefully set based on application torque requirements. Eccentric bearing sleeves are also adjusted by our experienced technicians.

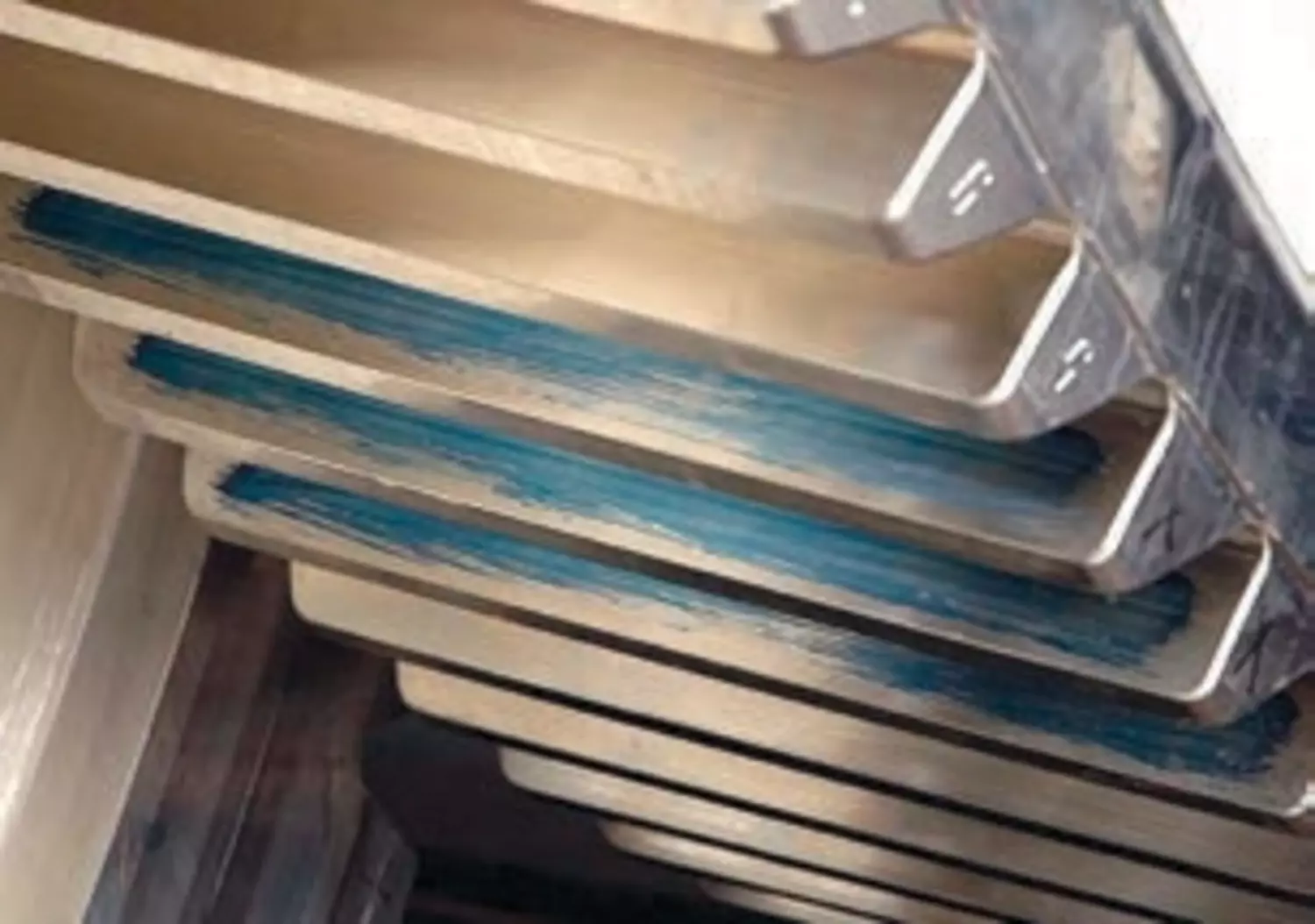

To confirm the contact pattern meets exacting OEM specifications, photos and dimensional pattern information are sent to SMS group engineering where they are checked and verified. Eccentric bearing sleeves are then dowel-pinned into locking position and final assembly is completed. After case bolts are tensioned to specifications, your drivetrain unit is thoroughly cleaned, painted to specifications and prepared for return to your rolling mill. Stringent machining and assembly procedures and tolerances are followed throughout our repair and manufacturing process to ensure the rebuilt drivetrain unit or component provides dependable service. In addition, we are a fully certified ISO 9001:2008 company that adheres to strict quality standards throughout the repair process.

Field inspection, alignment

Our experienced field service technicians are available to make sure your drivetrain equipment functions correctly and double-check gear tooth alignment, if needed, when the unit is reinstalled in the mill. We also provide laser-alignment services to ensure precise alignment.

Responsive turnaround

When rebuild turnaround depends on spare parts, as soon as we know equipment is coming to our facility, we initiate the process to locate or manufacture them. Because we have extensive repair experience and well-equipped facilities, we also have the ability and resources to do emergency and expedited repairs.

Excellent ROI

SMS group can repair or rebuild drivetrain equipment so it provides reliable service and performs like new at significantly less cost than new equipment or to provide costeffective spares. To learn more about our knowledgeable gear box repair services, call +1-412-231-1200.

Gear contact pattern is tested to ensure proper alignment

After reassembly, bearing end play is carefully checked