Our experience as a rolling mill manufacturer as well as our many years of teamwork with customers provides the best foundation for manufacturing oil film bearings. It’s the exact process-know-how we apply to develop and produce such high-quality products – always with a focus on cost effectiveness. Plus there is our Hilchenbach production plant that ranks among the most modern in the world. Immediately next to each other are the development, design/engineering, and manufacturing stations. That strengthens highly efficient processes and close technological cooperation under one roof. The result? Innovative designs for modern roll-neck bearings. Included in our X-Roll® Oil Bearing portfolio besides oil film bearings for new plants are custom modernizations as well as extensive services.

First-hand, expert knowledge - also available at your plant

Consulting

You get all the expert consulting you need to ensure effective operation of your plants. Wherever in the world you are, our experts stand by your side with these services:

- Technical assistance

- Damage analysis / troubleshooting

- Operating personnel training in theory and practice

- Bearing inspection support

- Upgrading to the latest bearing technology

- Supervision of installation and commissioning of bearings and hydrostatic systems

Spare Parts

- We only supply first-class spare parts that guarantee your plants operate efficiently. Here is what we can do for you:

- We determine your specific spare parts requirements

- Rapidly deliver spare parts for all oil film bearing types in OEM quality

- Draw up framework contracts on spare parts supply and stock

Top quality for you from your own workshop

Repairs

Also included in our services are expert repairs of these bearing components:

- Neck sleeves

- Bearing bushes

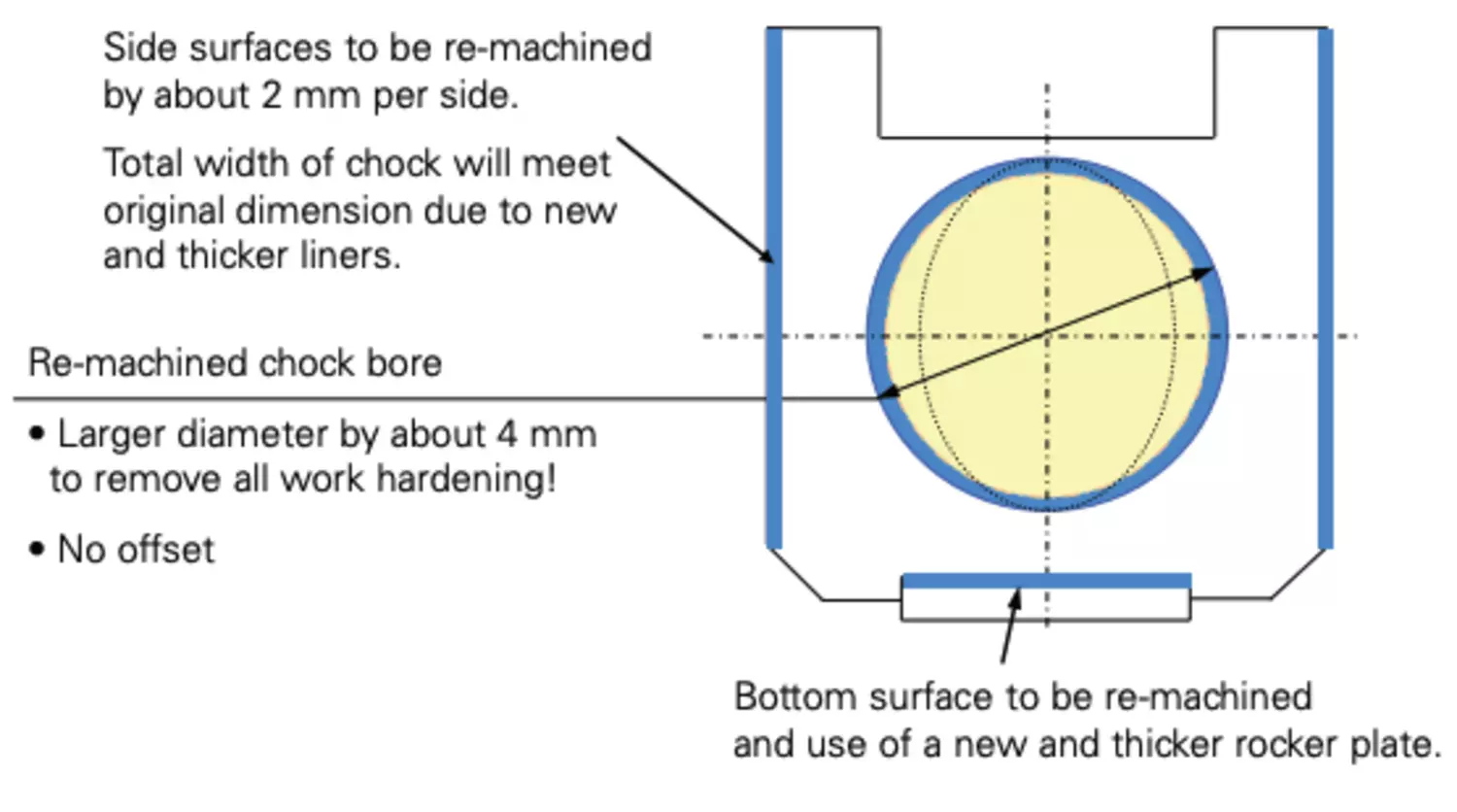

- Chocks

It often makes sense to combine repairs with technical improvements to components.

Manufacturing

What makes us stand out are state-of-the-art production equipment and over 60 years’ experience in manufacturing oil film bearings. More than 36,000 bearings supplied for our own mills as well as competitors’ plants clearly show that our components are not only first rate but also utterly dependable.

Process know-how for successful improvements

Modernizations

It’s vital for you to achieve high product quality at minimum cost. You can do this by keeping your plants up to the latest development standards. Even old equipment can regain its competitiveness through tailor-made revamps of specific components. Choosing SMS means you get the right partner to boost your profitability. We work closely with your production department, roll workshop, and maintenance crew to identify the current status of your plant. Then, on the basis of an in-depth analysis, our experienced service, design/engineering, and development specialists determine what optimizations will get the best out of your systems. Practical improvements such as safe handling of the bearings or better sealing systems are possible in many areas ... and they can make all the difference. That applies to all components – from the bearings and their chocks to the rolls and oil lubrication systems. So it pays to take advantage of our design ideas and systematic developments because they ensure your bearings meet the high standards essential for your business.