With innovative solutions, SMS group addresses the challenges of transforming non-ferrous metal slags into valuable products while recovering energy, reducing dumping costs, and enhancing sustainability. Through advanced furnace designs and cutting-edge technologies, SMS group offers clients the opportunity to maximize the value of their byproducts and comply with environmental standards.

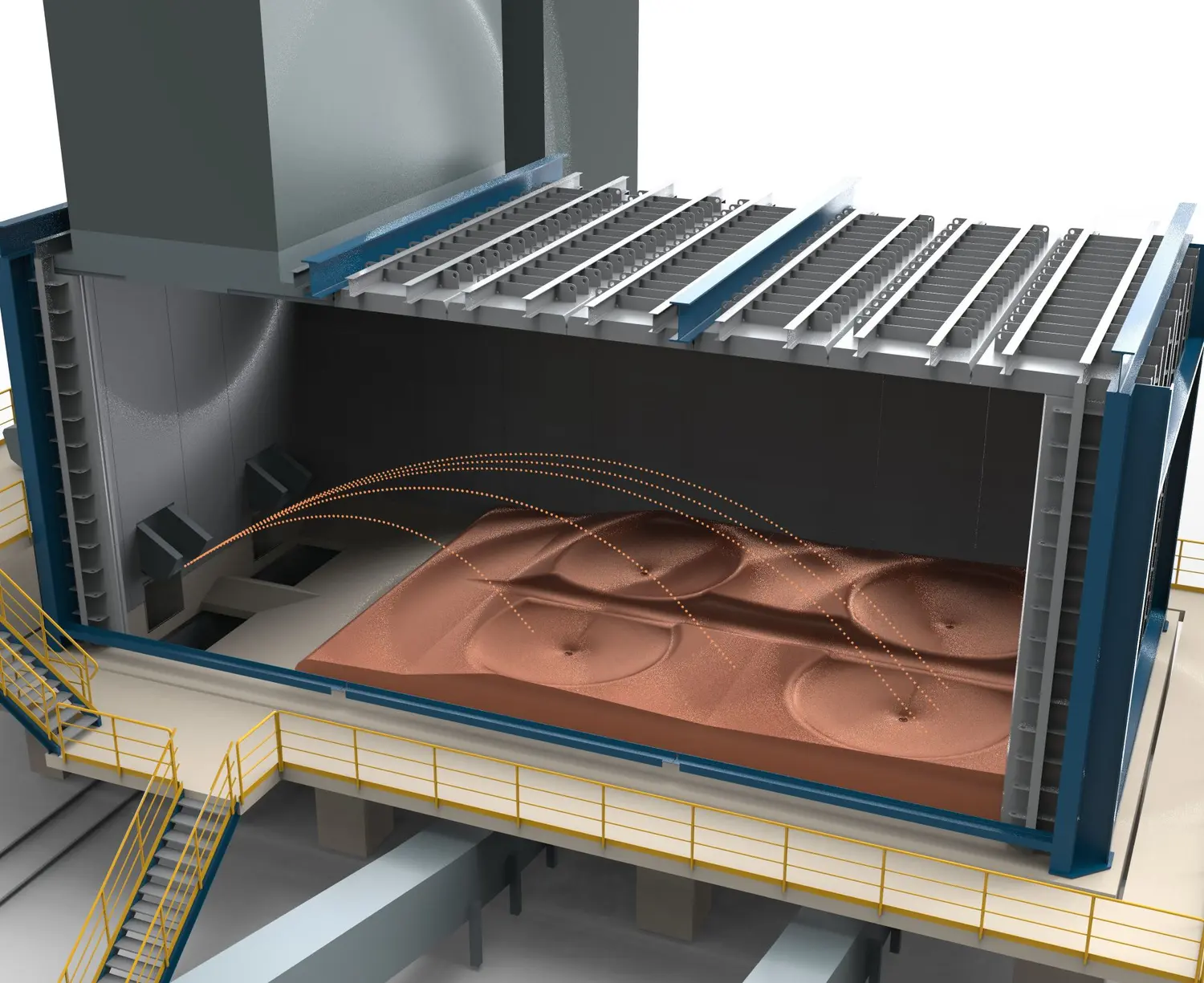

Main units for slag treatment are the electric slag settling and cleaning furnaces. Depending on the slag properties and volumes, rectangular or circular solutions can also be applied. Slags can also be treated with our basic rotary refiner, top blown converters and special drum type furnaces.

-

Submerged arc furnace (SAF)

Solutions for best non-ferrous metals and alloys production

Submerged arc furnaces excel in smelting ore concentrate, calcine, pre-reduced ores, and waste materials such as deposits, flue dust, slags, refractory breakout waste, and skulls. These units are highly versatile and tailored to specific input materials and product requirements.

Product portfolio:

- AC-based submerged arc furnaces (3- or 6-electrode systems; up to 140 MVA)

- Next-generation DC furnaces for niche processes (FeCr fines, TiO₂ slag, UG2, copper, PGM, recycling)

- Custom electric smelters for ferro-alloys, non-ferrous metals and specialty feedstocks

-

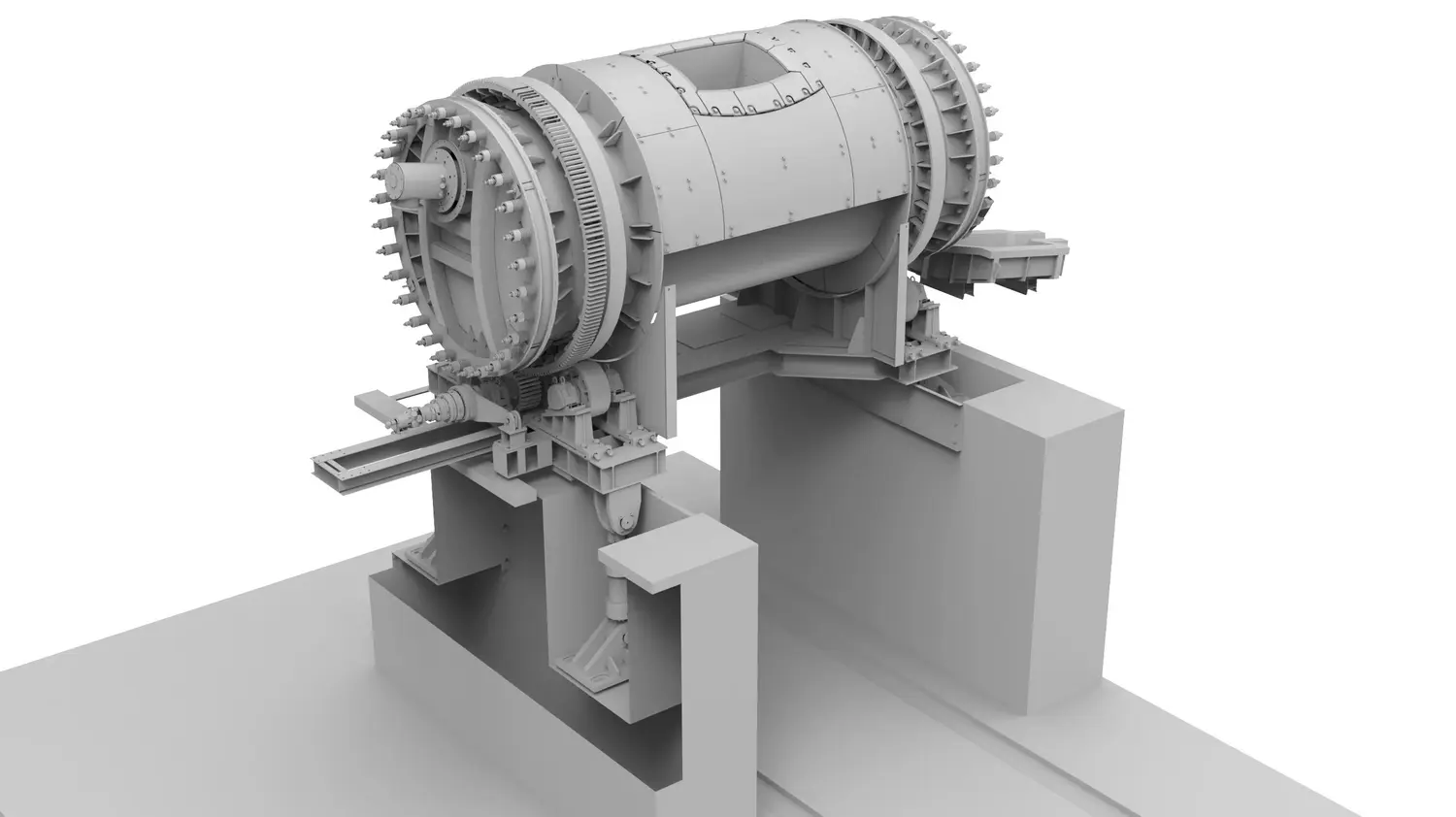

Basic rotary refiner (BRR)

Melting and refining of slags in one flexible, compact unit

BRR stems from the widely spread TBR (top blown rotary converter), which is applied in many fields for different kinds of operation and process. While it keeps it´s core competences in the field of slag treatment, aluminum and copper recycling, the narrowed field of application allows a much simpler and compact build-up.

-

Slag granulation for non-ferrous metals

SMS group’s DrySlag/PowerSlag systems and Paul Wurth’s INBA® technology set new benchmarks in non-ferrous slag processing—delivering superior slag quality, energy recovery and turnkey granular-product handling.

![]()

-

Lead-tin alloy furnace

Innovative bath smelting technology

SMS group has developed its own primary smelting technology, the so-called BlueSmelter. The BlueSmelter is an innovative bath smelting technology, which processes primary raw materials for nonferrous metals production, such as copper concentrate and other ores to produce zinc, lead, tin, and other metals. The BlueSmelter was designed to process a wide range of copper and precious metals containing secondary raw materials, with a focus on low qualities and high organic content but with significant monetary value.

![]()

Benefits

- Broad feed flexibility: concentrates, oxides, slimes and organics-rich residues

- Maximized metal yield and reduced slag losses

- Proven pilot-scale performance and technical feasibility

- Simplified maintenance and lower total cost of ownership