Benefits

- From 6 to 13 €/t savings according to bar size

- From 6.0 to 43 mm in diameter without equipment changes

- One bar per notch (better counting operations)

- 8,000,000 ton per line (two drums) without the need for spares due to wear

- Up to 2% material yield increase due to the reduction of short bars in case of multi-strand bar rolling

Soft-breaking-rolls for flawless bar quality

The key to efficiently discharging bars onto the cooling bed is a sensitive pressure setting of the pinch rolls. SMS group utilizes a proportional valve that individually regulates the pressure, according to the bar’s size and surface temperature. The system applies enough pressure to reliably slow the bars down without marking or deforming it. The result: top-notch bar quality. The bars are delivered onto the cooling bed via rotating channels. They are precisely synchronized with the soft bar breaking unit, the cooling bed cycle movement and the barposition monitoring system. This set-up guarantees that only one bar per notch is discharged. Plant operators benefit from trouble-free production and reliable counting of the rolled bars.

High speed and increased productivity are by far not the only advantages of HSD®: Rolling mill operators achieve closest product tolerances as well as optimum bar lengths. They also facilitate rolling management and equipment maintenance at the same time. Furthermore, plant operators minimize production costs with HSD®.

Latest out of total 104 worldwide plant references:

Yuxi Yukun I&S Co. Ltd. | P.R. of China | 2022 |

Abul Khair Steel Melting Ltd. | Bangladesh | 2022 |

GV do Brasil - Pindamongahaba | Brazil | 2021 |

GV do Brasil - Cariacica | Brazil | 2021 |

Wuhan I&S group | P.R. of China | 2021 |

Shandong Laigang Yongfeng Steel | P.R. of China | 2020 |

Improved product quality

High speed and increased productivity are by far not the only advantages of HSD®: Rolling mill operators achieve closest product tolerances as well as optimum bar lengths. They also facilitate rolling management and equipment maintenance at the same time. Furthermore, plant operators minimize production costs with HSD®.

Technical characteristics

- Exactly the right length of a bar at any speed with a cut-to-length shear and precise automation system

- Soft breaking-rolls for flawless bar quality for not quenched products

- Easier and smooth production process through the patented rotating channel

- Capability of processing rounds and deformed bars from 6 to 43 mm in diameter at a production speed of 52.5 m/s

- Offline HSD® capability in case of maintenance (when required) or rolling sections and profiles on aprons

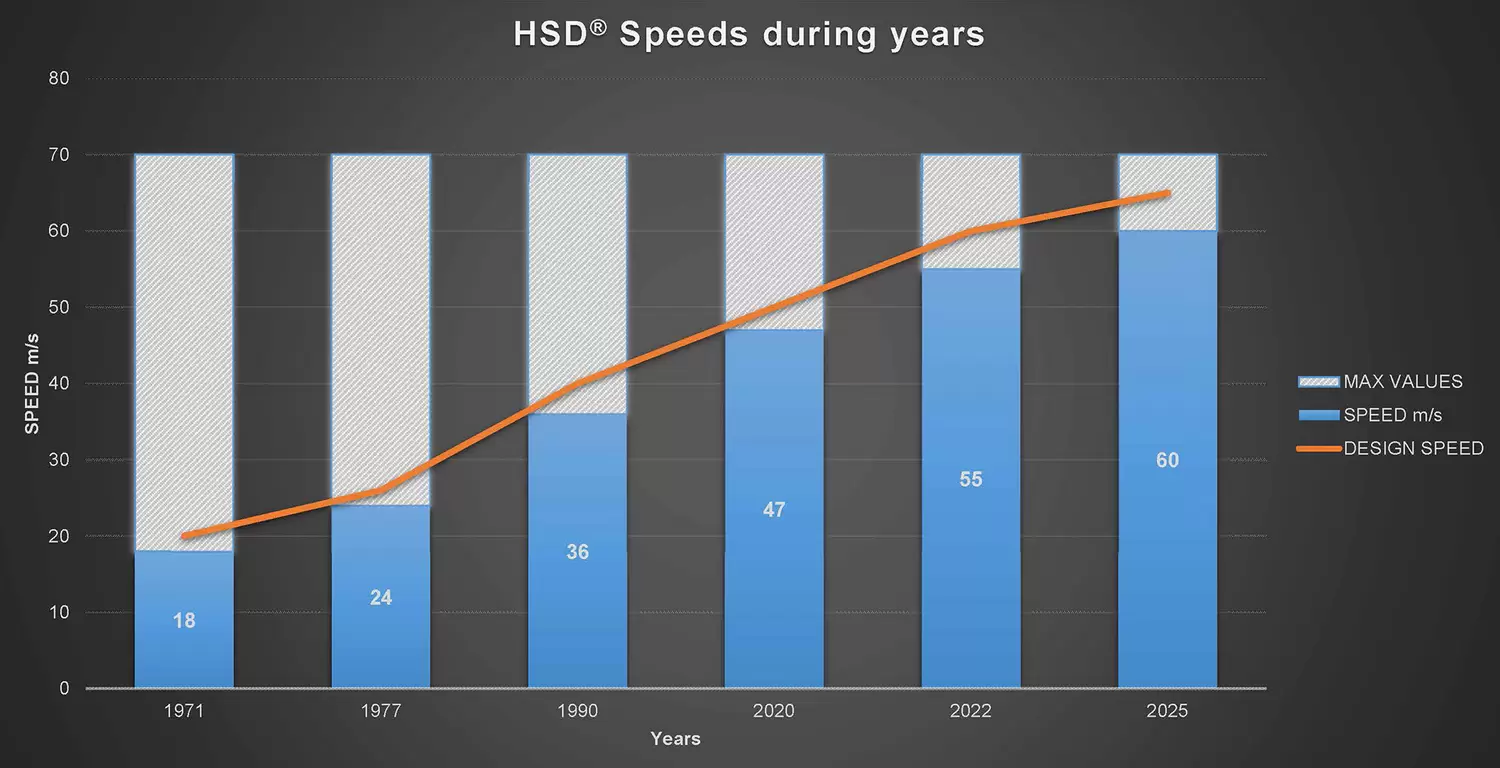

- The system is ready for the ultra-speed of 60 m/s and more with the newly VHSD® (Very High Speed Delivery) system