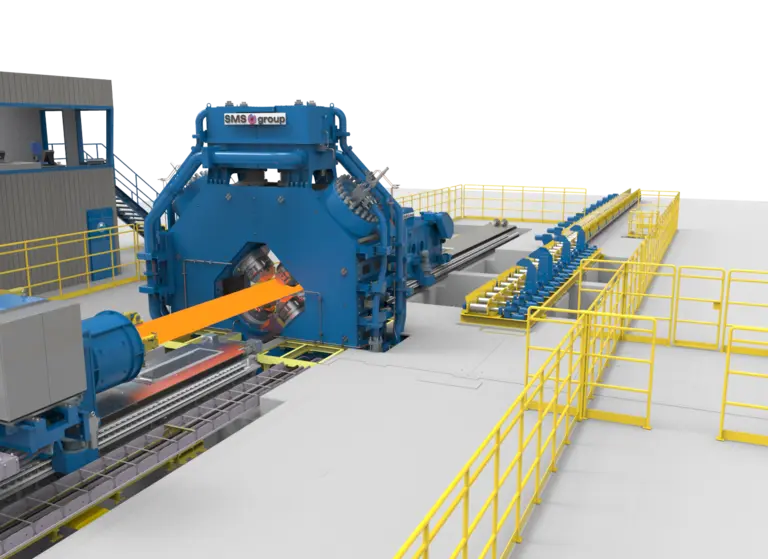

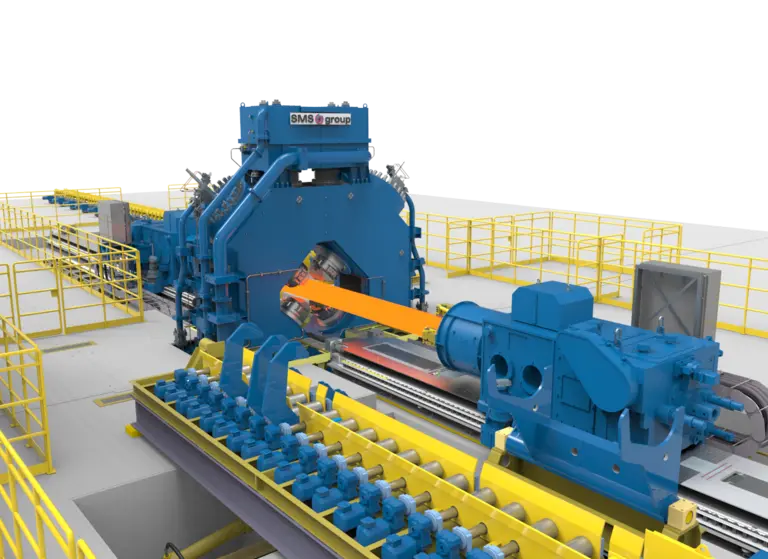

Open-die forging machine and radial forging press for aerospace and medical sectors

SMS group has supplied two advanced forging machines to US-American titanium specialist Perryman Company. The scope included a 40/45 MN high-speed open-die forging press and an SMX 500/15 MN hydraulic radial forging machine, complete with fully integrated process and production control systems.

This technology is important for Perryman as it enhances productivity through precise forging process control, ensuring consistent quality in titanium materials. These innovations position Perryman to meet growing market demands of the aerospace and medical industries. Production commenced around mid-2024 with the sequential commissioning of the forging line components. By the end of 2024, operations began with the radial forging machine, incorporating extensive line control. Further optimizations and acceptance are scheduled for 2025, followed by a swift transition to full production.

The innovative aspect of the new forging machines for Perryman Company lies in their comprehensive integration of advanced digitalization and technology packages, which significantly enhance productivity and quality control. The project includes a 40/45 MN high-speed open-die forging press and an SMX 500/15 MN hydraulic radial forging machine, with two forging manipulators. These machines are complemented by a fully integrated process and production control system that covers the entire forging line. The open-die forging press is designed to initially shape titanium billets to the required size, which are then finish-forged into bars of various shapes and lengths up to 14,000 millimeters in the radial forging machine. This comprehensive package is tailored to enhance Perryman’s production capabilities, particularly in producing high-performance titanium materials for the aerospace and medical sectors.

The technology embedded in these machines makes them highly efficient by incorporating advanced digital tools and systems. The MIDIS+ system manages and coordinates all production sequences, ensuring smooth operations and smart production planning. ForgeBase® and Comforge® technology packages allow for precise configuration of forging strategies by considering material properties and process parameters, with real-time data evaluation and visualization enabling continuous optimization during forging. The digitalization tools SMS-Metrics and Smart Alarm provide real-time monitoring and analysis of machine data to detect anomalies early, preventing costly shutdowns. Additionally, the Maintenance Advisor supports preventive maintenance, improving machine availability and ensuring consistent production quality. This integration of technology streamlines operations, reduces downtime, and enhances overall efficiency.