One of the world’s most powerful screw presses for aerospace and energy component forging

Wuxi Turbine Blade (WTB), a global player in the challenging market of high-quality components for aerospace and the power industries, uses advanced forging equipment from the SMS group to meet rising requirements of its customers in safety-critical sectors.

The company relies on the SPKA 22400 screw press for cost‑efficient production of large, high‑strength alloy turbine blades and aero‑engine components that must withstand increasing dimensions and loads while reducing component weight. With a press force of 35,500 t, it is one of the world’s most powerful screw presses. Only a few pressing operations are required for each workpiece thanks to high forming forces with a short contact time. This significantly reduces wear on the dies and brings costs down. At the same time, the microstructure of the workpieces remains homogeneous.

The working principle

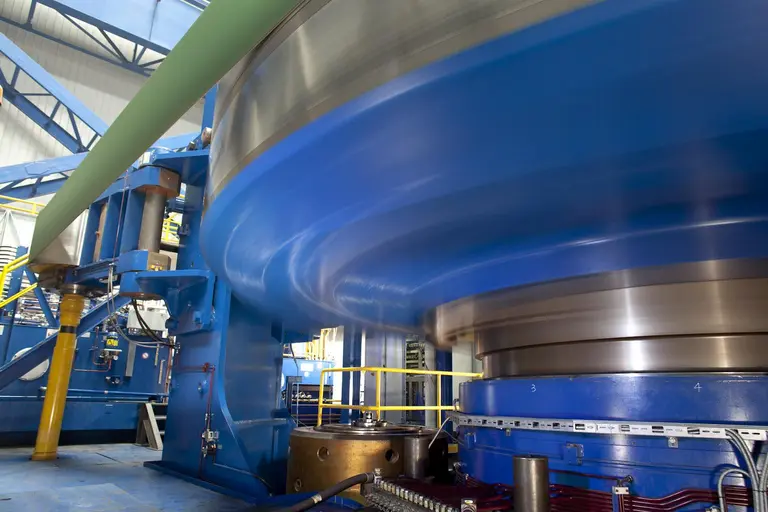

The powerful forming energy of the SPKA 22400 is provided by the main flywheel. It is the energy accumulator of the screw press and rotates at up to 36 rpm with a moving load of 590 t. The clutch, with a closing force of approx. 40,000 kN, is integrated in the flywheel and during forming it transmits a torque of almost 60,000 kNm to the screw. Within a few milliseconds of reaching maximum force, the clutch opens and separates flywheel and screw.

Strong partnership

WTB operates three key screw presses from the SMS group in total: the SPKA 22400, SPKA 11200 and HSPRZ 630 hydraulic screw press. The long-standing partnership between WTB and the SMS group, built on mutual trust and innovation, exemplifies technical expertise and responsiveness to the aerospace and energy sectors' evolving needs. This collaboration is a model for success in the global metals industry.

Impressions

Main data

- Press force: 35,500 t

- Weight of flywheel: 590 t

- Diameter of flywheel: 7,500 mm

- Weight of screw: 82 t

- Diameter of screw: 1,320 mm

- Selectable stroke speed: 0.25–0.5 m/s