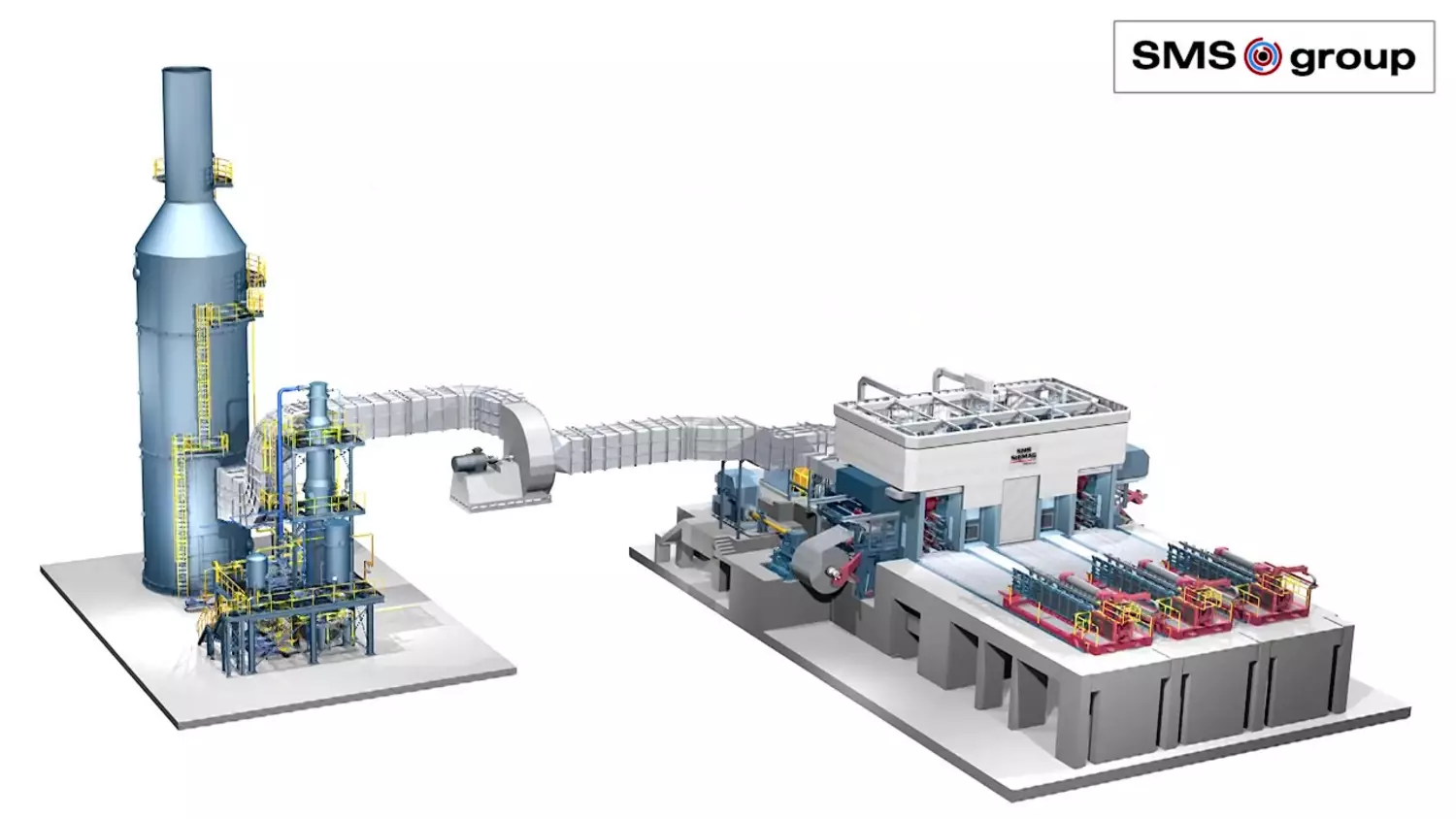

The Airwash™ system is one of our key technologies as we progress toward the "green aluminum coil". It not only ensures clean exhaust air from the process but also helps to significantly reduce rolling oil consumption. Our Greek customer ElvalHalcor S.A. recently started operating an Airwash™ system that is truly superlative in design and performance.

Standout features of the Airwash™ system include not only measured process data that verify the purification of the exhaust air, but also a large quantity of recovered rolling oil that is made available again for the rolling process. Both advantages are increasingly gaining significance when it comes to economic and ecologic aluminum production.

Adel Jonas Al-Kargholi, Expert for Fluid Systems at SMS group: “Our Airwash™ exhaust air purification system, equipped with state-of-the-art monitoring and safety systems, is a world leader when it comes to performance and efficiency. Like with the Elval order, remote access to the control system is possible after approval by the customer, for remote diagnosis, adaptations and program optimization."

At present, there are five new systems at different levels of completion, including supplies for ADI Aluminum Dynamics (USA), Latem Aluminium (Spain), Hindalco (India), and ASAŞ (Turkey).

The ElvalHalcor success story

Since 2022, ElvalHalcor S.A. is operating the largest Airwash™ system ever built by SMS group at its Oinofyta site near Athens in Greece. With this investment, ElvalHalcor has taken another important step towards even more sustainable aluminum production and enhanced environmental protection. The Airwash™ system at ElvalHalcor was designed such that it can process the exhaust air volume of two existing and one future cold rolling mills. While the first cold rolling mill is already successfully hooked up to the Airwash™ system, the second cold mill is currently being prepared to be also connected. Although the two cold mills already require a remarkable exhaust air capacity, with a total capacity of 450,000 m3 per hour, the system still has sufficient spare capacity to handle a third rolling mill in the future. The Airwash™ system is designed to recover a maximum rolling oil quantity of 425 kilograms per hour.

Abdelaziz Chettouh, Technical Project Manager at SMS on the project: "After just over a year in operation, ElvalHalcor confirms their continued high satisfaction with the quality and the performance of the Airwash™ system we supplied. The measured purity of the exhaust air is excellent. Besides this ecological aspect, the fact that a significant volume of rolling oil is recovered for re-use pays off the investment in such a system within a few years, in particular in times of rising prices for rolling oil."