The basis for every premium thread is a highly quenched and tempered tube

The market for sophisticated OCTG products is continuously growing as more oil and gas production capacity needs to be created. Here, it mainly depends on the quality of the pipes and threads. The deeper and more complicated the exploration process, the higher the requirements. Above all, the proportion of high-pressure, high-temperature, and horizontal wells in use has increased significantly. This results in increasing demands on the pipe itself and on the pipe connections.

Here, heat treatment comes into play: This is where the tubes obtain their premium quality in terms of material and microstructural properties. Precise process temperature control produces the metallurgical parameters and mechanical properties of the final product. To enable further processing and use in oilfield applications, it is extremely important that the tubes have uniform mechanical properties over their entire length and cross section. This can only be achieved if a homogeneous pipe temperature is ensured throughout the entire production process. This is why customers can count on the tightest temperature tolerances with our hardening and tempering furnace technology.

The product demands for use in CCS (carbon capture and storage) applications are similar. Here, the sealing lips of the premium threads ensure the safe transport of CO2. At the same time, the pipes must be capable of withstanding corrosion, extreme sub-zero temperatures (down to -80°C) and temperature fluctuations.

The thread-cutting machine for oilfield tubing

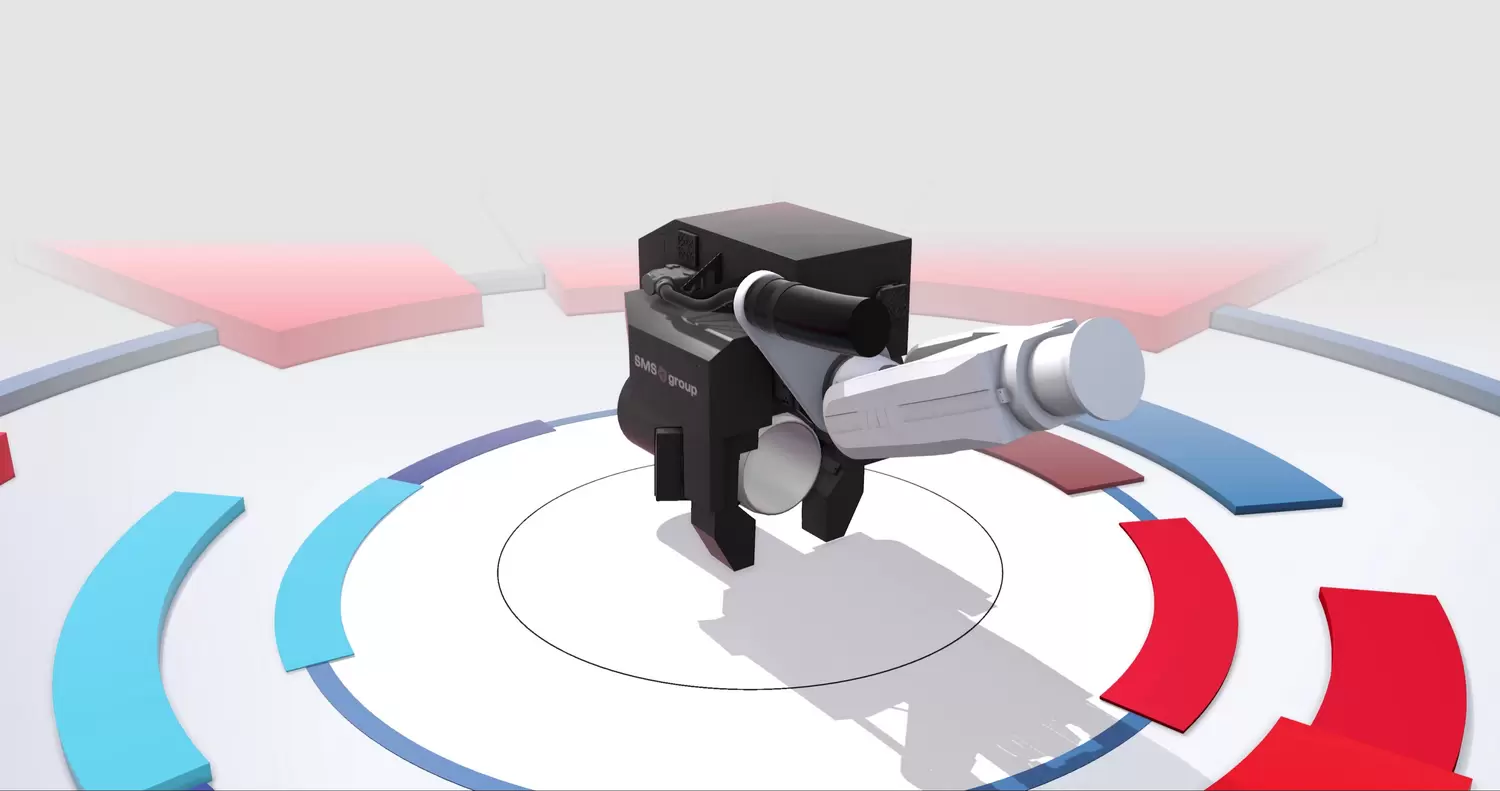

After the quenching and tempering process, threads are cut on the pipe ends. Yet is this as easy as it sounds? Anyone thinking of investing in a thread-cutting machine for OCTG threads today is spoiled for choice, because there is a wide range of machines available. SMS group’s solution, TCG, is now a well-established name on the market. Specially designed connections for oilfield tubulars in harsh pipe mill environments, the TCG offers unique precision. The machine’s rigidity and reduced vibrations play a critical role here. As a result, the TCG sets itself apart from the competition, especially when it comes to premium thread production.

Boosting product quality with integrated solutions for equipment and software

Producers of proprietary premium connections have their own inspection and testing requirements to ensure proper cut thread quality during production and in the field. Also some major oil companies have supplementary more stringent requirements for testing and inspection. In the past, these inspections could only be performed manually, which meant they were very challenging and time-consuming in a production environment. That is why we expanded our portfolio to include a thread measurement system, which can be fully integrated into the thread-cutting line. The system is called ThreadView and is the first to offer the option of measuring the negative flanks of premium threads, making it the missing building block in the realization of the thread’s complete digital twin. The system not only enables a 100 % measurement of all threads produced; it also ensures the pipe ends are evaluated, documented and saved.

ThreadView can be combined with our Quality Execution System (QES®). QES® captures and pools the quality data from various process stages. The software monitors, records, and ensures product and process quality along the whole production chain – from the raw material to the surface-finished final product. Rules are used in all process stages to check the extent to which quality standards are being maintained as per the customer’s specifications. The system includes all kinds of decision-making support that is important for the operation of the plant and for the process chain as well as for the delivery of the finished products. By combining ThreadView with QES®, we have the unique possibility of generating a full-blown digital twin of each tube, its thread, and its genealogy. Nearly all aspects related to a tube’s quality can be taken into consideration and analyzed. This is a major leap forward in terms of quality management, and a unique feature offered by SMS group.

Merging holistic product quality solutions with performance-based subscription models

We tackle product-quality-related issues by merging our integrated solution with performance-based subscription models. To do this, we carry out on-site assessments with the customer to identify improvement potential. Utilizing our product portfolio, we design and build tailor-made solutions that match our customers’ needs precisely. Alongside hardware such as the TCG thread-cutting machines and ThreadView, or software like QES®, these solutions include on-site operational support for maintenance and repairs, spare parts logistics, and consulting. Depending on the contract model, our customers do not just buy their custom solution package but also, for instance, pay per rated tube. Another example of a potential subscription model could involve sharing additional savings or profits between SMS group and our customer. In this way, we work with the customer to design not only an integrated solution but also a customized business model that takes us into a new era of partnership.