Here are the lines you need for producing silicon steel - from non-grain-oriented to highly permeable grain-oriented grades. You get complete plants from a single source, including mechanical, process and furnace technology as well as electrical and automation systems, plus process know-how. Furthermore, all our lines feature special equipment geared specifically to silicon steel strip.

Producing grain-oriented silicon steel involves several strip processing lines. The main elements are an annealing and pickling line (APL), a decarburizing and coating line (DCL), and a flattening and coating line (FCL).

Process know-how

Non-grain and grain oriented silicon steel strip

-

Annealing and coating line

Fully finished non-grain oriented (NGO)

Process sequence

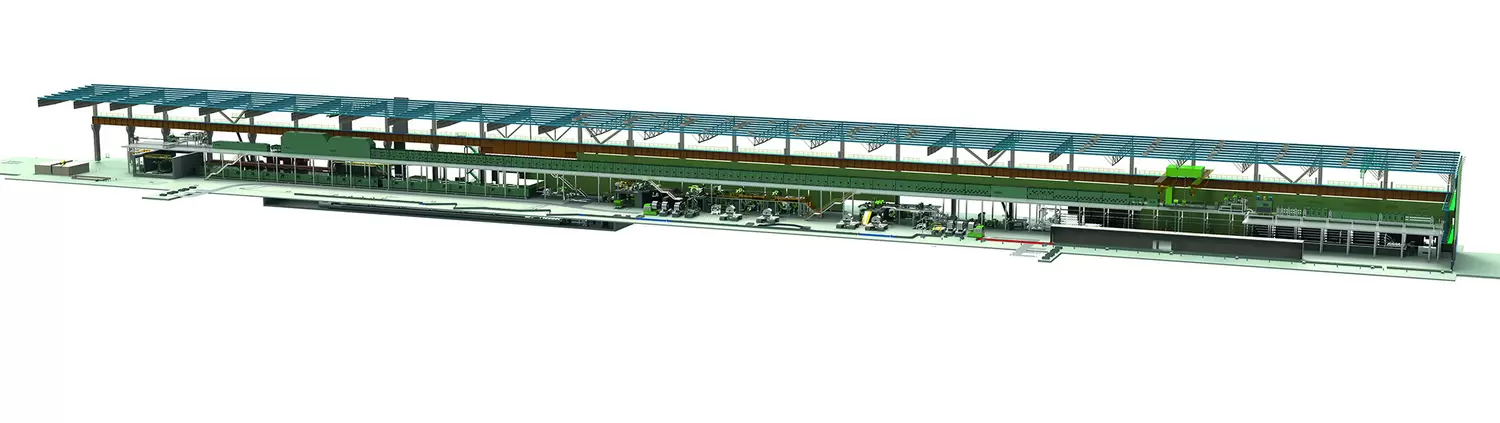

Annealing and coating lines (ACL) produce fully finished non-grain oriented (NGO) material. One highlight here is the recrystallization furnace with advanced water cooling and a hydrogen content of up to 100%. Equally important is advanced roll-coater technology with closed-loop thickness control. Finally, floatation furnaces with contactless drying of the coating and high specific heat transfer ensure excellent product quality.

So what exactly does an annealing and coating line do? It cleans, recrystallizes, and coats the steel with an insulation layer. Whenever the carbon content of the material is higher than approx. 30 ppm, a decarburization function must be integrated in the furnace. That prevents magnetic overaging.

![]()

Annealing and coating line -

Annealing and pickling line

For grain and non-grain oriented grades

Process sequence

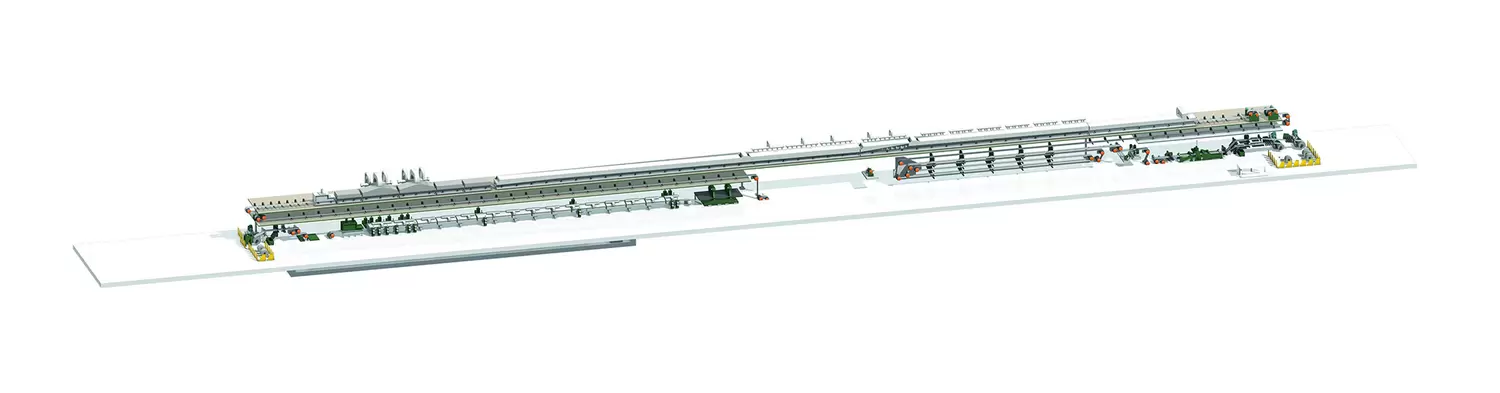

More versatile than other types, annealing and pickling lines anneal and descale grain-oriented as well as non-grain-oriented hot strip. SMS group supplies them together with components such as side trimmers with edge warming, state-of-the-art furnaces, and turbulence pickling tanks with special silicon desludging systems.

![]()

Annealing and pickling line (layout) -

Decarburizing and coating line

Processing lines for grain-oriented strip

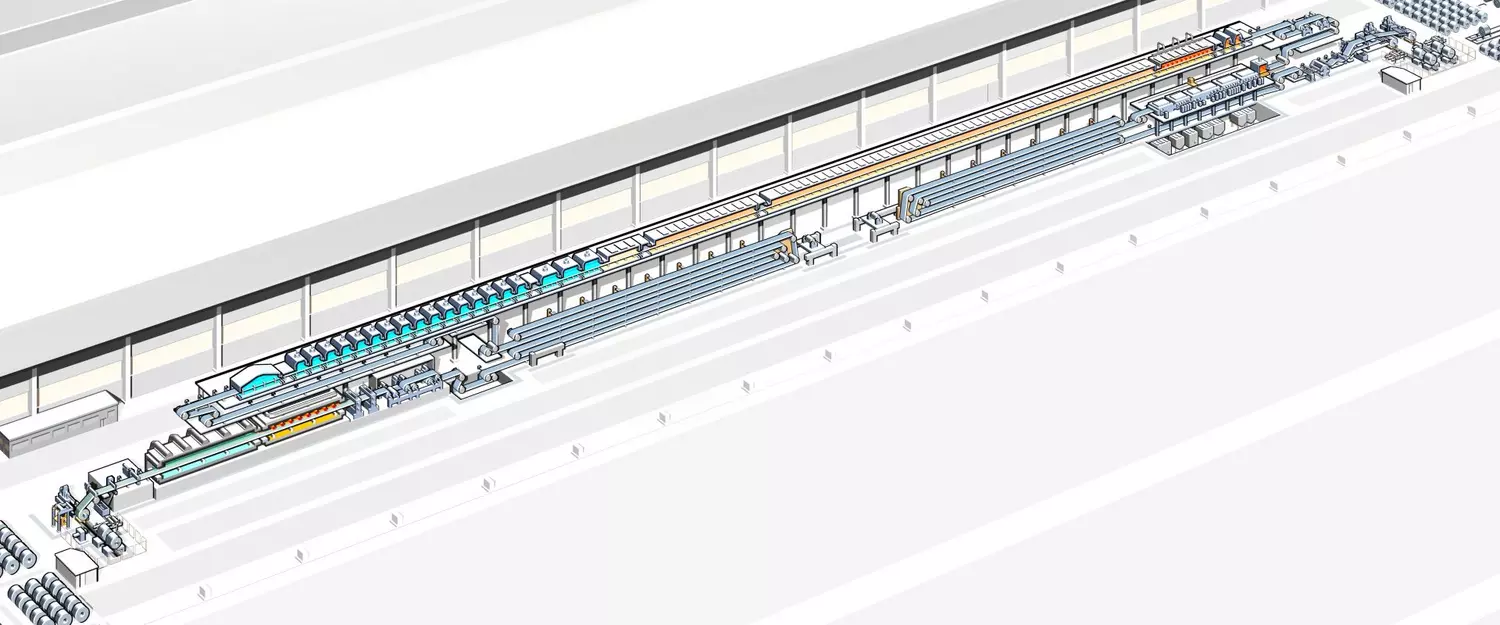

During decarburization annealing in the DCL, the atmosphere is humidified in the soaking section of the furnace to reduce the carbon content and thus avoid magnetic aging of the product. As an option, the furnace can serve also for nitriding. After annealing, the strip is coated with water-based magnesia slurry in a horizontal coater with closed-loop thickness control, temperature control and special conditioning of the coating solution.

![]()

-

Flattening and coating line

Grain-oriented processing lines

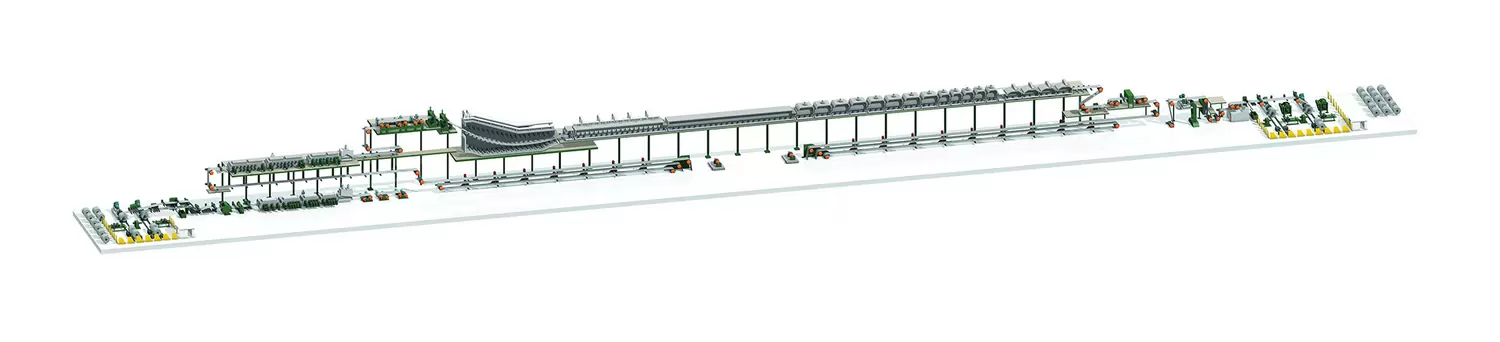

In the flattening and coating line the goal is to apply and dry the tension-active solution and to improve strip flatness. A horizontal coater with thickness control and accurate conditioning of the coating solution applies the isolation coating. A special feature is the filtration of the MgO solution, leading to a 90 % reduction in water consumption. The drying furnace is divided into a radiant-tube section for drying and a direct-fired section for sintering. The thermal flattening takes place in a horizontal furnace with tight strip tension control to avoid negative impact on final properties and to ensure improved flatness.

![]()

Flattening and coating line (Layout)

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Furnaces for annealing and pickling lines

Drever International furnaces allow heating the strip in a controlled atmosphere to avoid further oxidation of the surface before the pickling process. They also provide perfect control of the heating and cooling rates required to perform the heat treatment of the most advanced steel grades.

![]()

-

Furnaces for ACL, DCL, and FCL

Drever International furnaces in annealing and coating lines (ACL), decarburizing and coating lines (DCL), and flattening and coating lines (FCL) allow heating the strip in a controlled atmosphere to maintain a clean surface suitable for the coating process with magnesia. They also provide perfect control of the heating and cooling rates required to perform the heat treatment of the most advanced steel grades.

![]()

-

Special equipment

Ultimate solutions for silicon steel

We customize our special equipment for the particular requirements of silicon steel strip. Also important for you is that all components mesh with each other. That boosts the capacity, quality, and overall performance of these lines.

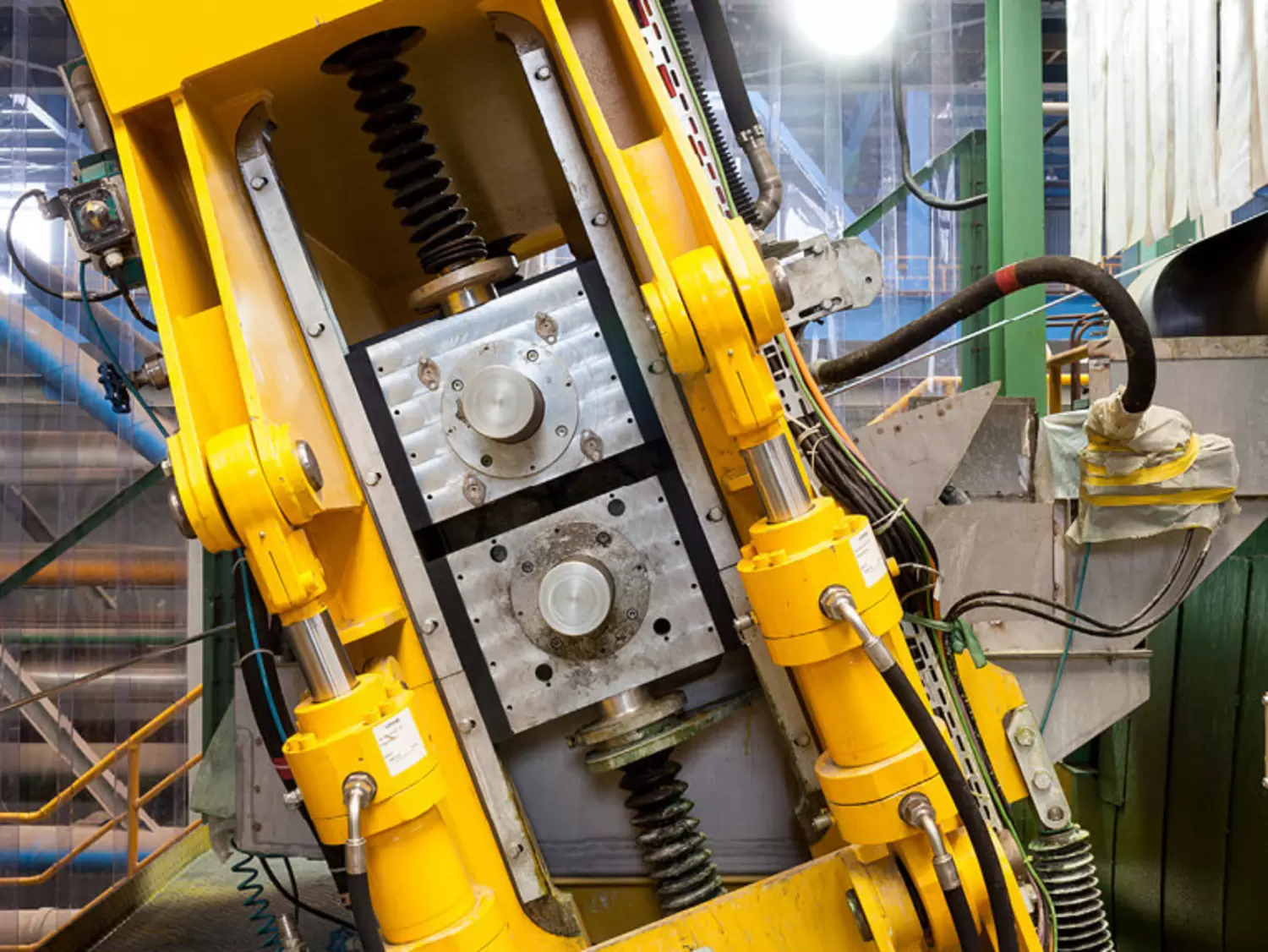

Our adapted turbulence pickling system involves a special tank shape and corresponding equipment in the circuit system to facilitate largely automated silicon oxide sludge removal. Heating the coils as well as the strip edges aids smooth strip running. This special handling also reduces strip damage and tearing. The coating has a crucial impact on the material properties of the final product. That's why we install special roll coaters for high-precision coating. Another feature that ensures top coating quality is exact temperature control of the coating medium in the circulation system.

![]()

High-precision roll coaters

Services for this plant

Sorry, there are no results for the search term.