Highly sensitive optical fibers for temperature measurements in the mold of a slab caster? At first glance, this seems like a contradiction. However, SMS group has succeeded in developing a solution for these tough everyday requirements of a continuous caster: HD moldFO+.

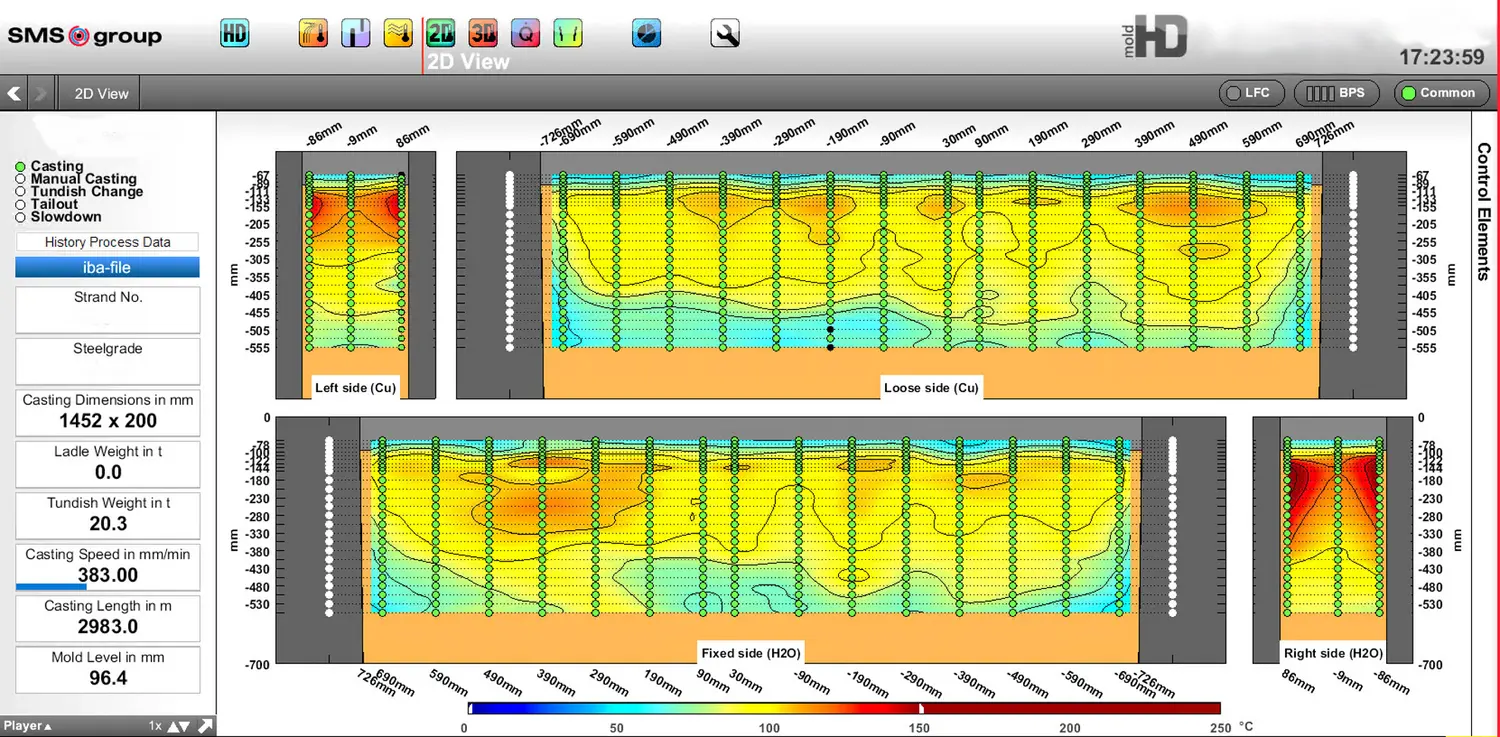

With 2,000 measuring points per mold, the exclusive SMS group system provides a precise, real-time thermal image of the casting process without blind spots, as with conventional thermocouples. This provides plant owners with the basis for reliable, continuous process monitoring along the entire mold. Deviations in heat transfer become visible at an early stage, reactions during operation can be controlled in a more targeted manner. The result: A more stable solidification, a more uniform product quality and a significantly lower risk of breakouts or unscheduled plant shutdowns.

Other advantages of HD moldFO+ include fast, simple commissioning, high reliability in continuous operation, simple servicing and the fast replacement of interrogators to sustainably increase the availability of a slab caster.

Temperature measurement via optical fiber works

“FO” in HD moldFO+ stand for “fiber optics”. An optical fiber contains lasered grids that reflect light at a defined wavelength. If the optical fiber heats up at a grid, it expands microscopically and the reflected wavelength changes. The temperature is precisely determined by means of this displacement. Each sensor rod in HD moldFO+ contains 25 such measuring points and until now up to 80 bars are embedded in a mold.

The result: 2,000 measuring points which provide a complete, high-resolution temperature profile along the entire mold with measured data in real time. This specialized device for fiber-optic measuring technology captures the reflected signals and their spectral displacements, which are then converted into temperature values and forwarded to the higher-level control technology via an ethernet interface.

The problem: Filigree technology, rough environment

Earlier optical fiber solutions for temperature measurement in molds had a structural problem: The evaluation unit – a sensitive interrogator with laser technology – had to be housed outside the casting platform in a switchgear room. These evaluation units must be connected to sensitive plug-type connections which had to be kept extremely clean, dry and vibration-free near to the dirty casting platform. In practice, these transitions proved to be a source of interference: Even slight soiling, minimal impurities or vibrations led to signal losses.

The susceptibility to failure and the complex maintenance effort made the technology unattractive for many operators despite its physical advantages.

The solution: Bring everything onto the mold

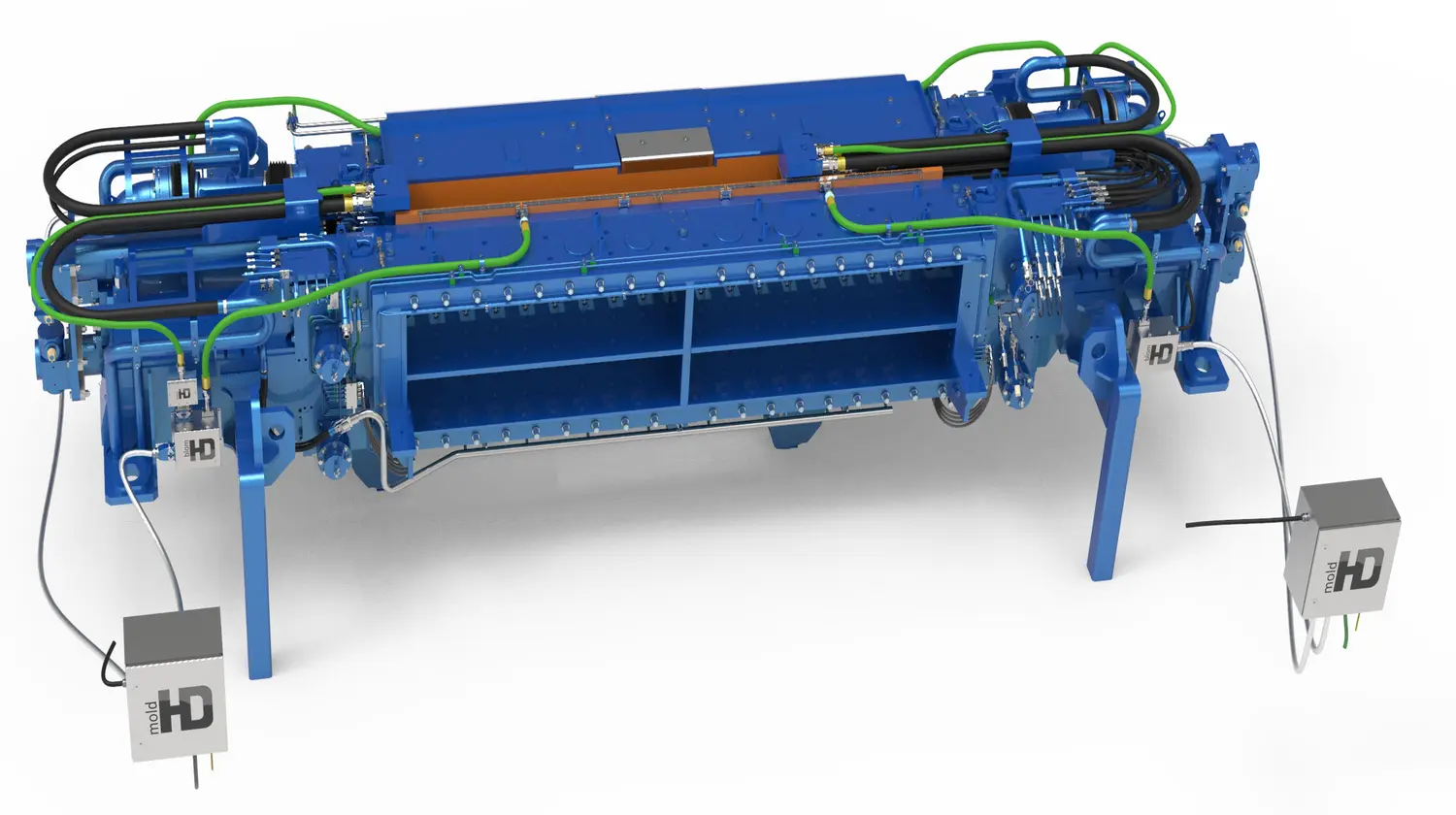

HD moldFO+ has solved the problem: Newly developed interrogators – i.e. the optical pulse generators and evaluation units – as well as the sensitive connection technology are now housed in a protected, compact housing, located directly on the mold. The connection to the sensors is permanently bolted and permanently closed. No more optical couplings, no more time-consuming adjustments, no sensitive plugs. The sensors are inserted into the copper plates, guided through robust corrugated stainless-steel hoses and connected directly to the interrogator in the protective housing for protection against electromagnetic fields. The complete unit is designed for industrial use.

In the past it was said that electronics were coming down from the mold. Now we are going exactly the opposite way. And it works very well. HD moldFO+ reliably withstands even extreme stirrer fields.

Applications with real added value

The high measurement density of HD moldFO+ opens new possibilities in the casting process, particularly where classical systems reach their limits. By contrast with thermocouples, which only cover about 100 measuring points, optical fibers with 2,000 measuring points provide temperature curves covering the whole mold. In addition to classic functions such as breakout prediction, mold temperature, clogging prediction, bulging prediction, SEN lifetime and friction, HD moldFO+ opens additional functions that can be implemented exclusively with this technology:

- Level Assist: Detects the shape of the mold level in real time over the entire width, irrespective of the mold powder.

- Solidification Assist: Calculates the optimum lubrication range of the casting flux and the solidification depth from the temperature field. Further information on the penetrating of liquid mold powder is visible.

- Taper Assist: Assesses the contact behavior between strand and narrow face by means of precise differential measurement.

"Data quality has changed radically. We recognize mold level dynamics, temperature distortions and lubrication curves in a degree of detail that did not exist before," says Stephan Six.

Simplified servicing

The system is not only robust, but also easy to maintain. Each interrogator is designed as a plug-in component and can be easily exchanged within about 10 minutes, independently of the customer's maintenance team.

The sensors remain untouched. Stephan Six on the practical experience with the new system, which is already in use by several customers: "Our sensors are installed once and remain there. Also during maintenance work. However, there are also exceptions: A Japanese customer has reported to us that he removes the sensors during refurbishment including new coating of the cooper plates and then reinstates the same sensors and puts them back into operation with stable performance without any problems. To date, he has already carried out this ten times. This shows how robust our technology is."

More control, higher availability

HD moldFO+ impresses not only with its new robust design and easy maintainability but also creates the preconditions for continuous and reliable monitoring of the mold: With a clear data basis for all process-relevant decisions. The high measurement density enables a holistic evaluation of the casting conditions in real time. Plant owners recognize critical developments at an early stage, stabilize the solidification in a more targeted manner and safeguard the quality even with changing operating parameters. At the same time, intervention and downtimes are reduced. In this way, HD moldFO+ makes a measurable contribution to increasing product quality, yield and plant availability.