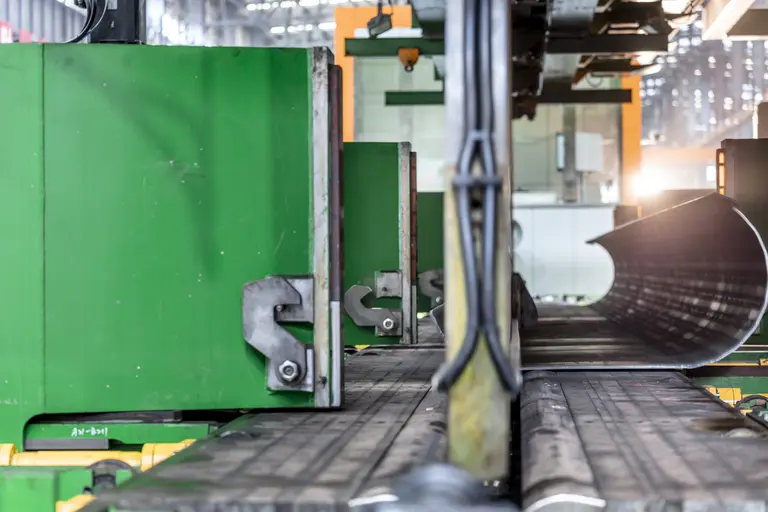

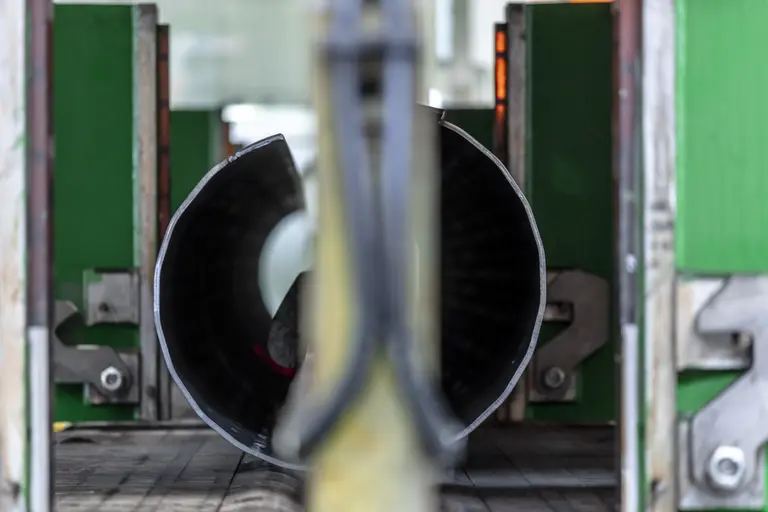

JCO forming process

Cost-effective forming with low carbon footprint

Main dataThree main forming processes have become established in LSAW tube production. We focus on the JCO process. This method is not only very flexible, it also requires lower investment compared to other methods. Therefore, it has quickly established itself on the market after its development by SMS group.

The process perfectly fits small and medium-sized production capacities and enables flexible production, covering regular up to very challenging pipe dimensions at high quality. But also high capacity plants (500,000+ tpa) can be realized. Thanks to the VSP (Variable Speed Pumps) hydraulic system, the JCO pipe forming press along with the crimping process offer economic and ecologic production with a low carbon footprint.