SMS group has installed a pioneering hydraulic closed-die forging machine in the U.S. for Weber Metals, which is part of the OTTO FUCHS group. The machine boasts a forging force of 540 meganewtons, which equates to 60,000 short tons. That is why the most powerful, most precise and most advanced press featuring digital technology is known simply as the 60k press.

A large-scale project

Experience the entire large-scale project implemented jointly by OTTO FUCHS and SMS group

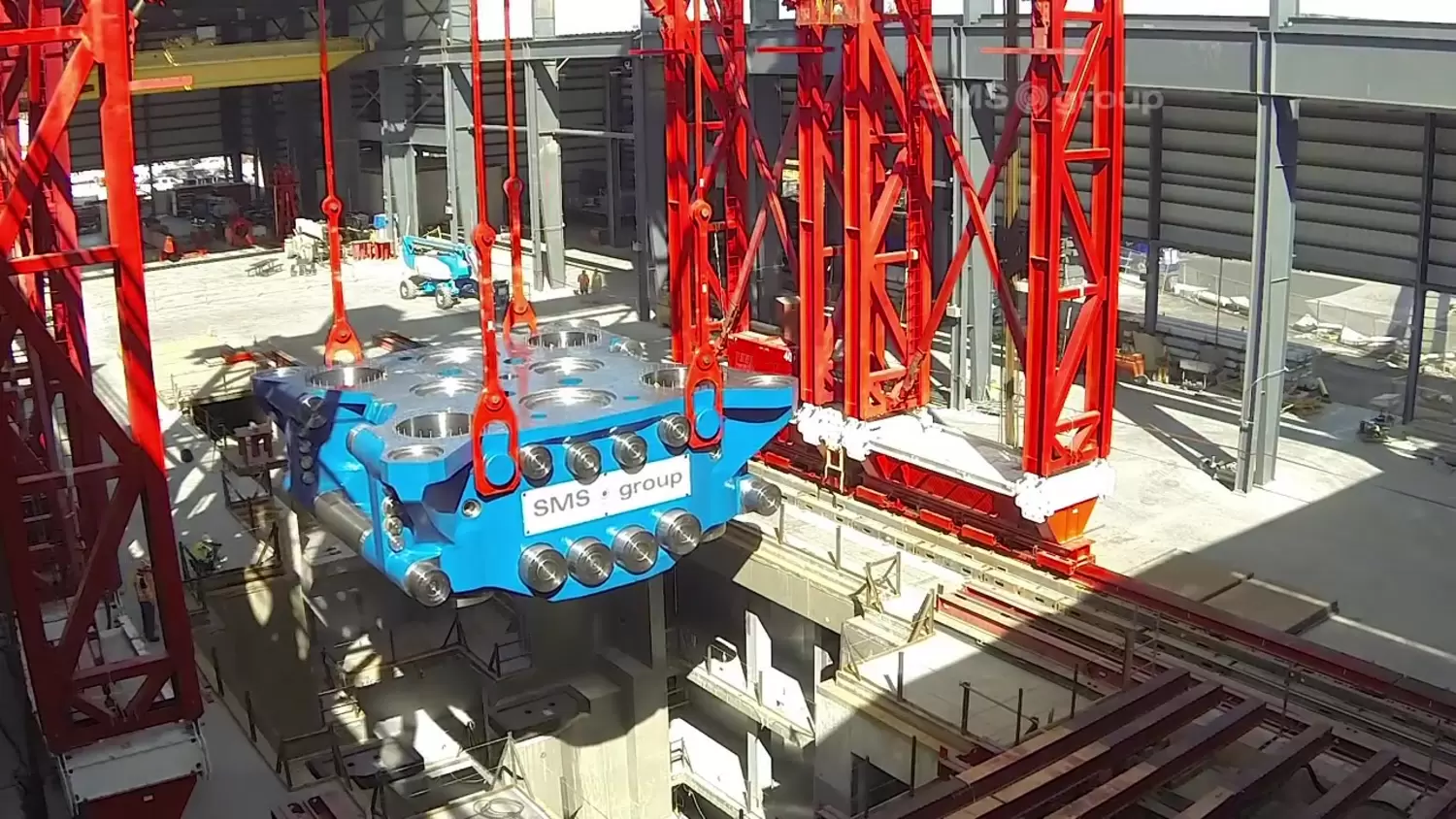

Erection and installation

How do you erect such a colossal plant that consists of 9,000 tons of steel and weighs more than the Eiffel Tower? A plant that requires a hydraulic system for 270,000 liters of oil and features cutting-edge digital technology with a massive network and over 3,000 sensors? Here you can get to know the people, the partners and the teams behind the successful erection and installation of the plant.

Background

For OTTO FUCHS the new closed-die forging press was not about setting world records but about opening up entirely new future prospects for the aviation industry. This forging press is capable of producing larger and lighter components. Find out all you need to know about the background to how and why the management chose this press.

Technology

This is not only the world's largest closed-die forging press, it is also the most fascinating in terms of technology. Here you can gain an insight into how the technology interacts with all the components and what it is capable of. Find out about the smart forging process, high precision, and outstanding automation and digitalization.