Acting economically - growing sustainably

Sustainability has a long tradition at SMS group. We have always been committed to green production and the construction of environmentally friendly plants. We continuously develop and optimize our entire plant technology to reduce the consumption of resources such as energy and water, to decrease the level of dust or noise emissions and to increase plant efficiency by means of improved yield or the reduction of scrap.

-

Our portfolio

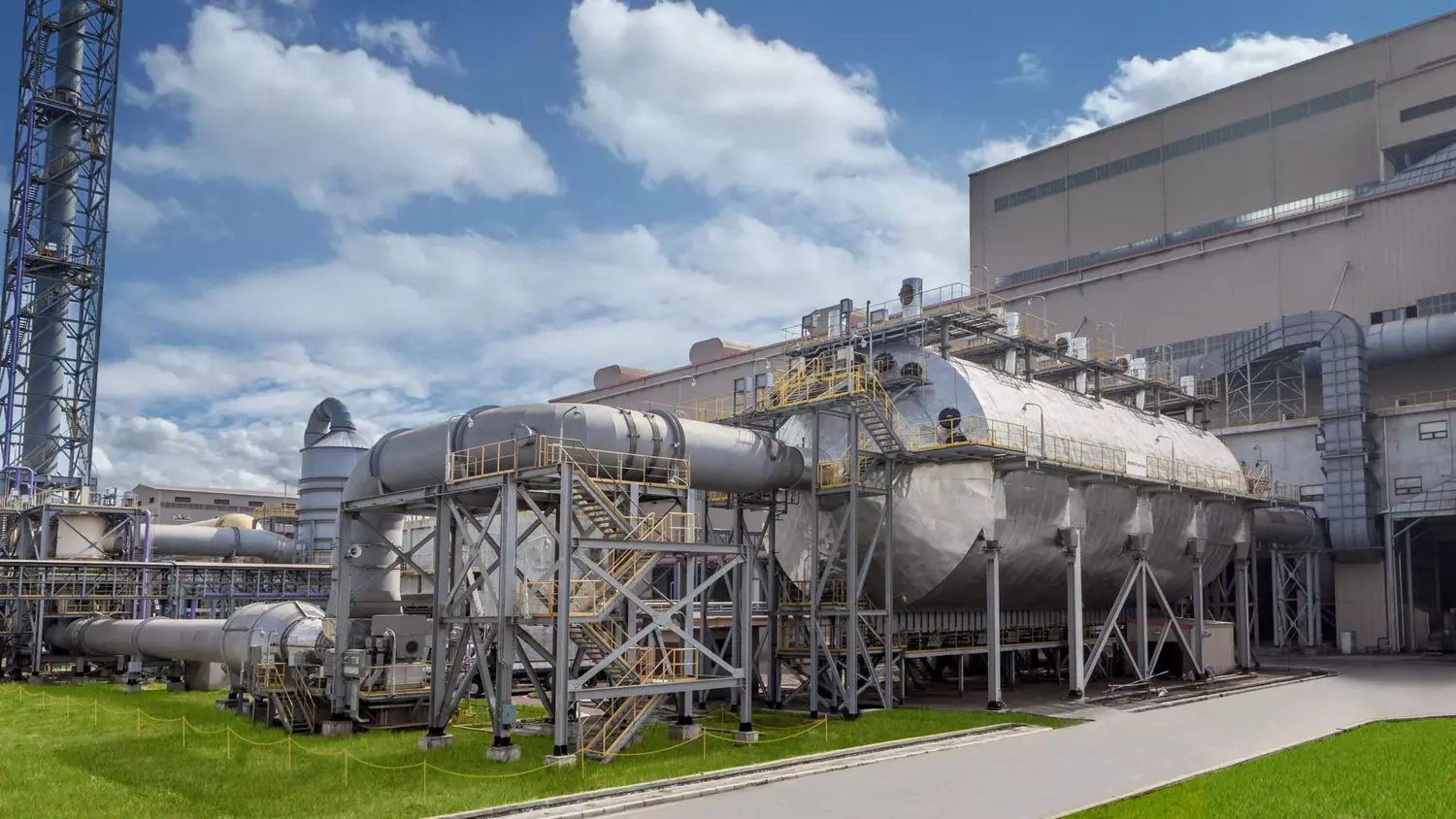

The melting process generates up to 20 kilograms of dust per ton of steel. This goes into the exhaust air where it represents a big problem. You need to clean the exhaust air to ensure sustainable steel production and comply with clean air regulations. Whatever your furnace type - whether electric-arc (EAF), basic oxygen (BOF converter), argon oxygen decarburization (AOD converter), or submerged-arc (SAF) - we offer you the right technology.

Our range includes:

- Complete gas cleaning plants for all metallurgical equipment

- Primary gas cooling / dedusting

- Secondary dedusting

- Gas recovery (BOF, SAF)

- Dedioxization (by lignite coke)

- Desulphurization

- EFATM process

![]()

-

Blast furnace top gas cleaning

Pollution control and energy recovery

A high-efficiency top gas cleaning system is vital for reliable operation and prolonged campaign life of gas and blast systems, energy recovery, and steam generation facilities. It allows the plant operators to meet the relevant pollution control standards.

Thanks to extensive expertise built up over decades, Paul Wurth is an environmental solution provider able to supply technology, systems, and equipment designed to the highest levels of cleaning efficiency, safety, and reliability.

With more than 140 references in blast furnace top gas cleaning worldwide, Paul Wurth offers proven design, plant, and core components, as well as plant improvement.

![]()

-

Gas cleaning plants for BOF converters

The challenge of gas cleaning is to provide maximum protection to humans, machinery, and to environment and to effieciently recover valuable constituents of the process gases. Our BOF (basic oxygen furnace) environmental systems ensure high efficiency in recovering these converter gases and offer considerable economic advantages.

![]()

-

Gas cleaning for electric arc furnaces

Our competence in the dedusting and gas cleaning of electric arc meltshops applies to the supply of equipment for new facilites and the modernization of existing facilities. The perfect interaction of all components reduces investment costs and improves efficiency.

![]()

-

Off-gas treatment

Off-gas composition in production plants for non-ferrous metals differs largely depending on the process and the charge mix in the furnace. Based on years of experience developing furnace processes and the downstream fume treatment process, SMS group’s expertise covers a wide range of existing plants and the necessary data from tests to accurately determine the gas compositions for all charge mixes. The fact that the furnace and the fume treatment plant were both developed by SMS group gives us in-depth knowledge and control over the entire process. Furthermore, we consider local conditions in determining the best solution for each application. For example, if water is scarce, a dry solution may be selected instead of a wet fume treatment alternative. Another example of local conditions to consider is the capability to recycle the dust that is filtered in the fume treatment plant. If that is an option, SMS group offers various solutions to recover valuable dust by sending it back to the furnace or storing it in some form. With years of experience developing such solutions, we also advise our customers on environmental regulations and the required solutions to acquire environmental permits while considering all the surrounding factors.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Our portfolio

The most important energy input in the steel industry comes in the form of heat. That goes for processes all along the process chain - from steelmaking plants to processing lines. Yet generating combustible gases often wastes precious thermal energy. That's why we developed several solutions to recover energy from:

- Hot off-gas from EAF, BOF, AOD, and SAF using evaporation-cooled ducts or waste heat boilers

- Combustible exhaust gases using industrial power plant technologies

- Hot off-gas with reheating furnaces

- Hot slabs with innovative heat exchangers

![]()

-

Steam generation

SMS group has developed an energy recovery system that utilizes the energy from hot processes to generate saturated steam in a boiler unit. The saturated steam can be used for various applications, including direct use as process steam as well as for drive units or for the generation of electrical energy in a turbo-generator unit. To ensure the system’s high availability and long lifetime, the boiler is fitted with cladding to protect it against high temperature corrosion. The recovery of energy contributes significantly towards increasing the energy efficiency of the plant and thus helps to reduce production costs and CO2 emissions.