Today’s world of new technologies, digitalization, and artificial intelligence offers us numerous possibilities to make our lives and work more comfortable, more profitable, and—at best—healthier. The same is true for the HD scan, a fundamentally innovative technology for assessing casting quality.

For over four decades, the traditional method for evaluating the quality of cast products has been macro-etching. This technique involves the use of hazardous chemicals, such as hot acids, applied to steel samples to reveal internal defects, which are then assessed visually. Despite efforts to automate this process through etching machines, image scanning of revealed defects, and other means, human error and subjective evaluation often result in significant measurement uncertainty.

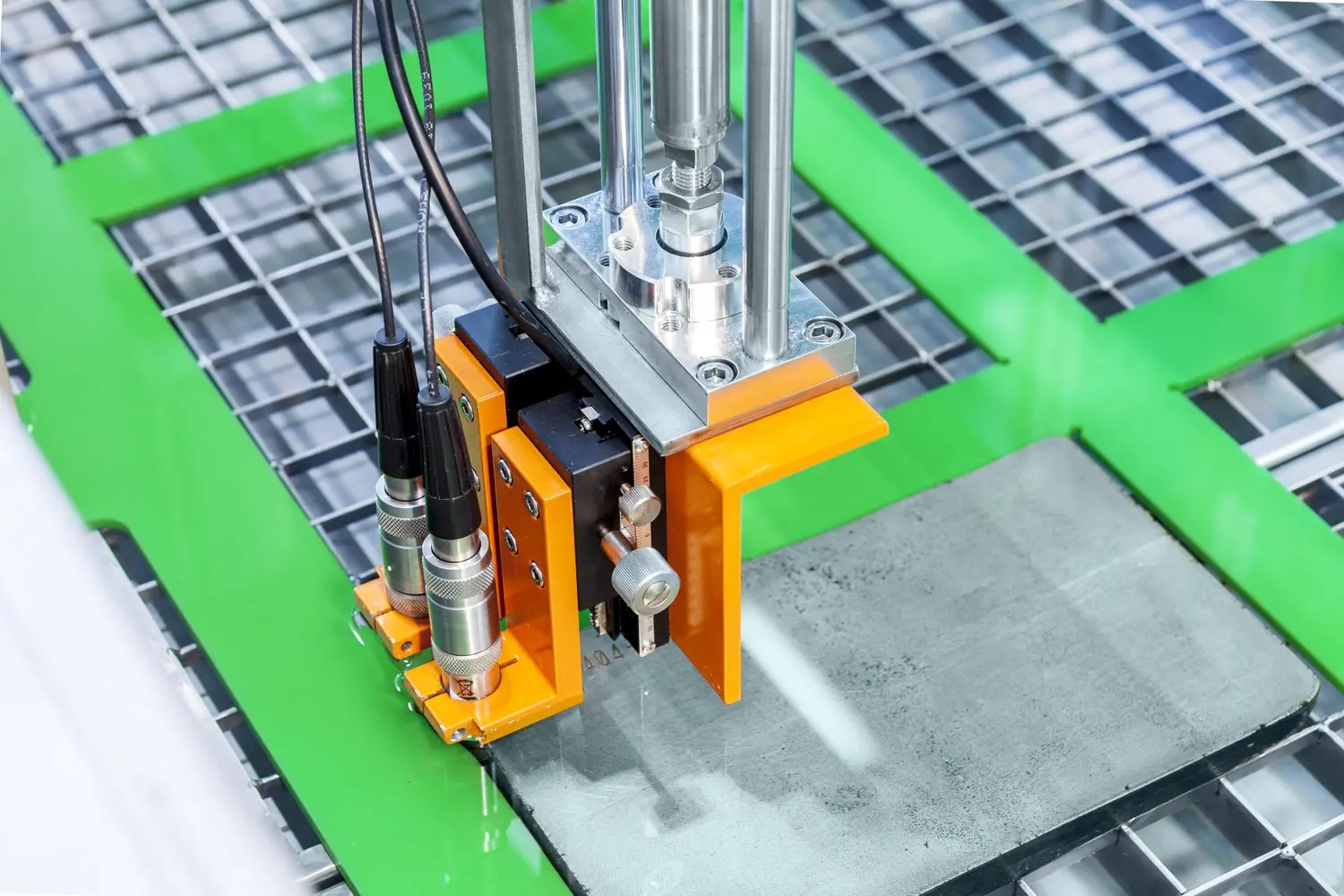

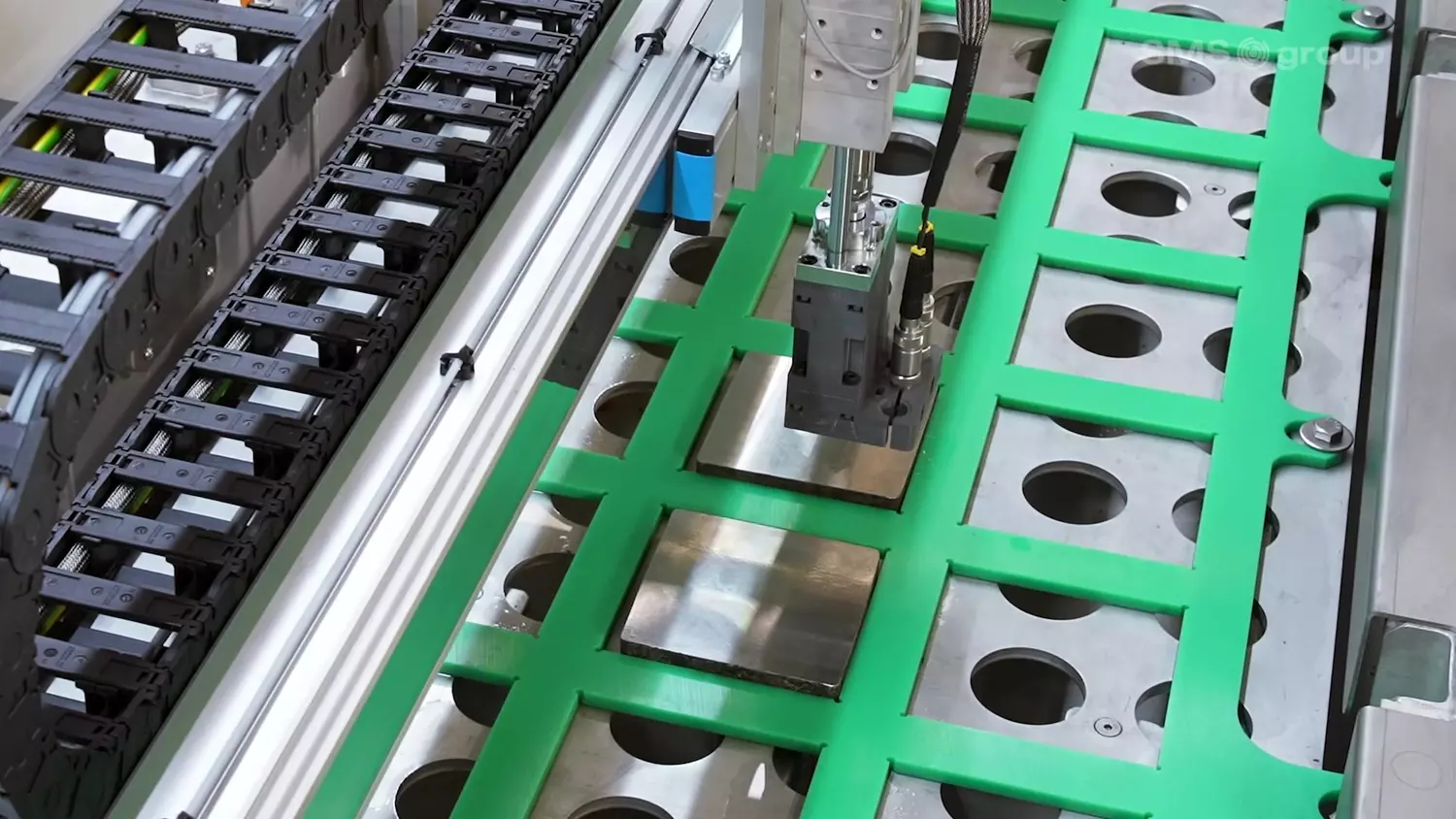

In 2015, SMS group introduced a groundbreaking technology for casting quality assessment known as the HD scan. Promoted under the motto "clean, safe, reliable", this method employs clean and safe ultrasound technology, requiring only electricity and ordinary tap water, thereby eliminating the need for hazardous substances. Digital evaluation is used to minimize human error, ensuring reliable results.

Digital solution with implemented AI

The main strength of HD scan lies in automated evaluation, which is controlled by advanced software. This enables the automatic generation of reports with objective results and provides easy access to statistics for further analysis and comparison. Artificial Intelligence (AI) technologies are integrated for tasks such as crack estimation, enhancing the convenience of the evaluation process.

The features of HD scan analysis are constantly evolving, with new features and functions being developed to meet the customer’s needs. The introduction of a cloud solution allows customers to access the latest software version, always updated with the most comprehensive set of functions. Additionally, the cloud offers a database feature that stores results, statistics, and images of customer samples in a customer-specific database. This database facilitates the comparison of different samples and the extrapolation of data for further evaluations. Access to this database is limited to the owner, so each customer can only see his or her own data.

The cloud solution serves as an alternative to traditional desktop software. The desktop software does not require internet access and can operate in a closed system, installed on a specific computer. Customers have the flexibility to choose between the cloud and the closed desktop solution, depending on their preferences and requirements.

Experience the HD scan technology for free

SMS group offers you a free analysis of up to three samples. If you are interested, please fill in the form and we will get in contact with you.

Casting process optimization

The digital information acquired through the HD scan can be directly leveraged for product optimization. To facilitate this, additional casting process information is necessary. Customers have the option to utilize their own casting process models or seek assistance from SMS.

While casting process optimization is distinct from the core HD scan software, the quality data essential for optimization is derived from the HD scan evaluation. This data extraction can be performed at any time by exporting the evaluated statistics to a separate file. The extracted statistics comprise various calculated parameters, which, in combination with casting models or other analyses, provide insights into process challenges and can help to develop suitable countermeasures. For example, the origin of the crack within the caster can be determined by recalculating the distance between a crack tip and the surface of a cast product. Consequently, the corresponding casting segment can be monitored and adjusted as required.

Additionally, the 3D visualization capability of the HD scan offers a significant advantage for investigating crack propagation. The macrostructure representation in the HD scan can assist in assessing the impact of Soft Reduction and other process parameters.

More information compared to traditional technique

The utilization of HD scanning technology, which allows for the examination of multiple internal layers within a sample, as opposed to the single surface layer visible through traditional macro-etching, offers a wealth of information regarding internal quality. This advancement enhances the reliability of measurement results and provides a more detailed perspective on flaw distribution and potential "problem zones." Several characteristic examples have been published previously. A recent investigation demonstrated the impact of this technology on optimizing casting processes, particularly in addressing internal cracks. As previously noted, estimating the origin of cracks is crucial for the development of countermeasures and the prevention of cracks in cast products. This involves measuring the distance between the internal crack and the surface of the casting product. In a specific customer case, results obtained from traditional macro-etching were misleading, as they suggested longer crack depths, leading to an erroneous focus on later casting segments.

HD scan delivers us an independent and consistent qualification of internal slab quality, with minimum maintenance costs and without use of chemicals. The analysis enables us to further develop our products and thus strengthen our market presence.

The comparative analysis of the results of HD scan and traditional techniques using hundreds of examples from different customers has shown a significant improvement in the volume of information with the new technology. Imagine the analysis as with magnetic resonance imaging (MRI). This opens new possibilities for further process optimization and research areas for investigation.

I would like to express my gratitude for your support during the commissioning of the unit. When people working truly together the results are imminent and guaranteed despite some trouble on the way. HD scan will be concrete pillar for our further quality improvements and product development towards current customer retention and mostly new customer acquisition.

HD scan modifications: right choice for customer needs

To date, six industrial HD scan systems and two HD scan LAB units have been produced. The initial pilot HD scan unit has been operational since 2015 and is exceptionally robust. The only component that needs to be replaced regularly is the ultrasound sensor, a commercial spare part with a minimum life of two years. Beyond the initial pilot unit, customers in the Netherlands, Saudi Arabia, Turkey, and the United States have acquired additional industrial units. The industrial HD scan units are available in the sizes M, L, and XL, corresponding to scanning lengths of 1500 mm, 2000 mm, and 2500 mm, respectively, with a scanning width of 600 mm. The optimal machine size is determined based on customer requirements, particularly sample throughput and the number of work shifts. Continuous personnel availability is not necessary, as the operator is only required during the loading and unloading phase, which takes about half an hour. The machine then operates autonomously for five to six hours and thus enables overnight measurements in two-shift plant operation.

The HD scan LAB units are mobile laboratories that can be deployed outdoors on site at the customer’s premises, requiring only an electrical connection. These units are a modification of a smaller HD scan unit housed in a construction container, including a comfortable workspace, window, heating, and air conditioning. The primary objective of this modification is to facilitate the easy relocation of the HD scan system between commissioning sites, providing rapid feedback on casting quality. This modification can be rented monthly. The HD scan LAB was successfully presented at the SMS Caster Fair in India in 2024, and a further unit is available in the USA.

After numerous customer requests, a third modification of the HD scan was developed: HD scan Mini, a laboratory unit like the HD scan LAB, but without the container and workplace. Designed for use in any laboratory, whether in the factory or at a specialist company, this smaller unit is ideal for customers with low sample throughput or for complementary research and development activities. We would like to point out that the HD Scan LAB can only be rented at locations on the European mainland. SMS thus offers tailor-made solutions to meet a wide range of customer requirements effectively.

Experience the HD scan technology for free

SMS group offers you a free analysis of up to three samples. If you are interested, please fill in the form and we will get in contact with you.