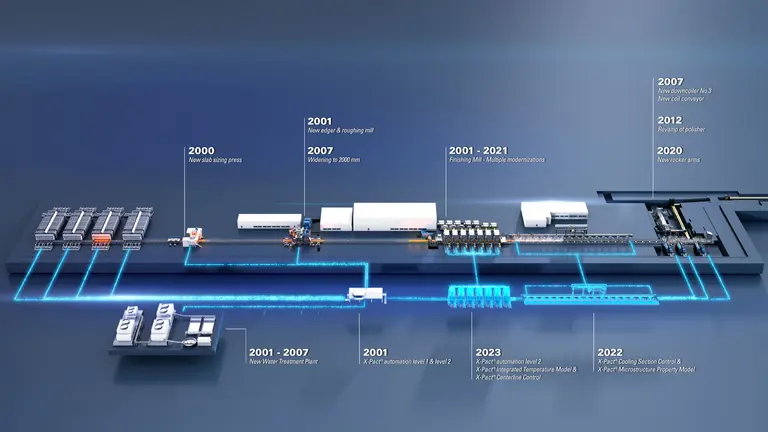

Since the commissioning of Salzgitter Flachstahl's hot strip mill (HSM) in 1963, the mill has frequently been upgraded with latest technology. The strategic partnership between SMS group and Salzgitter Flachstahl GmbH enables the systematic further development of the HSM.

The ongoing improvement of the plant is guided by a service framework agreement. This agreement encompasses various initiatives aimed at enhancing plant performance, with active involvement from the Research and Development department of SMS group. There is a productive exchange of ideas with the R&D department, especially concerning rolling technology. Additionally, a dedicated emergency support system is in place to address incidents at the plant with the highest priority, ensuring the reliable and cost-effective operation of equipment and automation systems. The 24/7 hotline and X-Pact® Service Portal facilitate swift issue resolution, reducing costs and improving performance.

The steering committee maintains a constructive dialogue on current projects, leading to the joint development of solutions across diverse applications. Regular technology days are organized to exchange insights on current trends, market requirements, and new opportunities. This long-standing cooperation between SMS group and Salzgitter Flachstahl GmbH has resulted in numerous modernization measures on the HSM. Below is a selection of the most significant measures undertaken.

As a result of the activities described below, the annual capacity of the high-performance hot rolling mill was increased from 3.5 million tons up to 3.8 million tons. Another important achievement is the rollable strip width. The original maximum hot strip width was 1,880 mm. Since the extensive revamp measures taken in the first decade of the 2000s, hot strip with a maximum width of 2.000 mm can be rolled. The upgrading of the plant can be demonstrated very well by the concrete example of pipe grades. Before the major revamp activities have started in the early 2000s, the HSM was able to produce X70 in maximum width up to 1,880 mm and maximum thickness of 19.0 mm. After the major upgrades, X80 can be produced in width up to 2,000 mm with 25.4 mm maximum thickness.

But what are the steps in detail? Learn more about the main measures and modernization phases in chronological order.

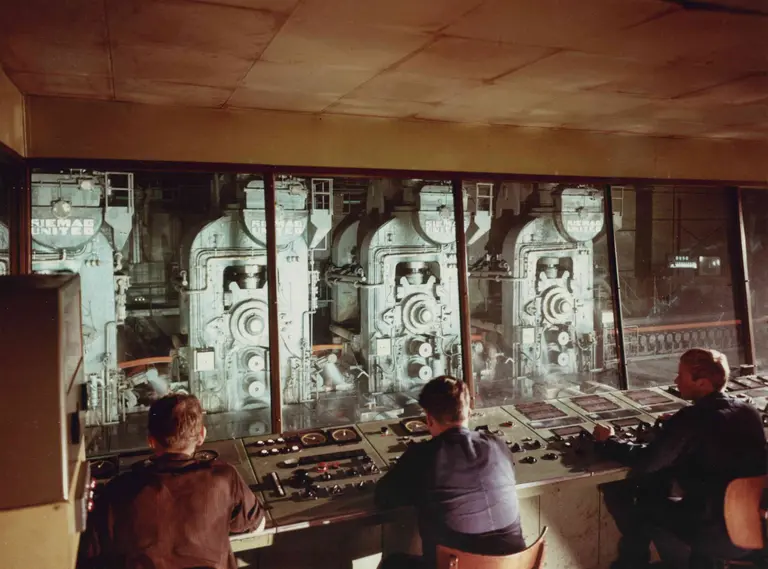

1965 – 1999: Expansion and enhancement

The HSM at Salzgitter Flachstahl GmbH was a success right from the beginning. After two years of operation in 1965, the exit section had to be extended by a second downcoiler. Until 1998, both of the downcoilers experienced several modifications and upgrades, like e.g hydraulic side guides and hydraulic step control for both coilers.

To extend the capacity of the finishing mill, two additional finishing stands, F6 and F7, were installed in the late 1960s and early 1970s. The roll change process was enhanced with the introduction of roll changing equipment. In the 1990s, stands F1 to F6 were equipped with hydraulic loopers to ensure stable strip flow through the finishing mill. All mill stands received new work rolls and interstand strip cooling systems. Regarding the actuators, stands F6 and F7 were outfitted with the modern CVC® plus system for roll shifting, combined with work roll bending. At this point in time, CVC® plus was still a young technology from SMS group that would make a significant contribution to the efficiency of the finishing mill. Today, CVC® plus is one of the world's leading rolling technologies. In parallel, in 1993, SMS group upgraded the automation system, focusing on profile and flatness control systems.

Other significant installations included the rotating drum shear in 1975 and the laminar strip cooling system in 1982.

2000 – 2007: New equipment

The first decade after the turn of the millennium brought an important step forward for the performance of the HSM. With the modernization measures, which started in 2000, Salzgitter Flachstahl GmbH pursued two essential objectives: Enhancement of the spectrum of steel grades and boost of production. This is why the modernization measures implemented from the year 2000 onward have focused on all areas of the plant, including the roughing mill, and have incorporated integrated solutions for both mechanics and automation. At the dawn of the new millennium, a new slab sizing press and a roughing stand with an edger were installed in the roughing mill area. During this period, the finishing mill stands F2 to F5 were equipped with the current combined CVC® plus work roll shifting and bending system, similar to the upgrades previously made to stands F6 and F7. These extensive mechanical modifications, initiated in 2001, were effectively complemented by the integration of Level 1 and Level 2 X-Pact® automation technology from SMS group.

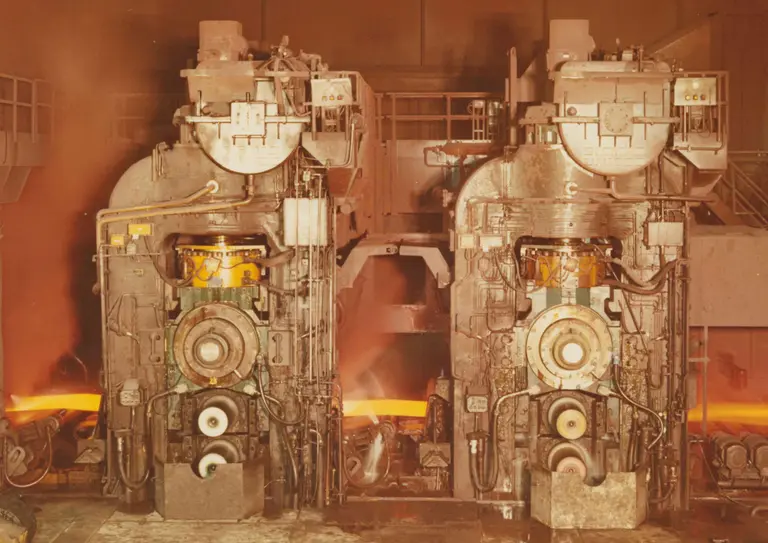

2007 – 2011: A massive capacity increase

In 2007, there started a most challenging project. Salzgitter Flachstahl GmbH not only wanted to expand the product mix of the rollable steel grades but also to increase the width of the hot rolled strips by 120 mm. Therefore, the width of the roughing mill was expanded to 2,000 mm, necessitating significant adjustments in the downstream plant areas, particularly in the finishing mill.

As part of the project to extend the finishing mill, the first mill stand (F1) was equipped with the combined CVC® plus work roll shifting and bending system. All mill stands were fitted with new drives. The exchange of motors and gears was done step by step in the years 2009 to 2012. The new drive system comes with increased rolling torques, which have a significant impact on the product mix and enable not only finish rolling of ultra-high strength grades but also to roll wider products.

New entry and exit side guides, along with work roll cooling, were installed at each mill stand. The finishing mill upgrades were completed with the addition of roll gap lubrication for stands F1 through F4. All these measures were executed in 2007. The modifications also extended to the downcoiler area, where a third downcoiler of the Uni Plus type was installed, along with a new coil conveyor, which included a telescope straightener, in the same year.

The substantial increase in performance and capacity also impacted the utility and auxiliary systems. Consequently, a new water treatment plant was introduced to the hot strip mill in the same year.

Since 2012: Steady improvements

Following this extensive expansion, SMS group has been regularly commissioned to perform systematic upgrades. In 2012, a significant revamp of the polisher in the downcoiler area was undertaken. Further mechanical revamps also focused on enhancing the downcoilers.

In 2020, SMS group upgraded the downcoilers and supplied new rocker arms equipped with the latest generation of polishing devices. This supply included mechanical equipment, electrical components, and automation systems, as well as installation services.

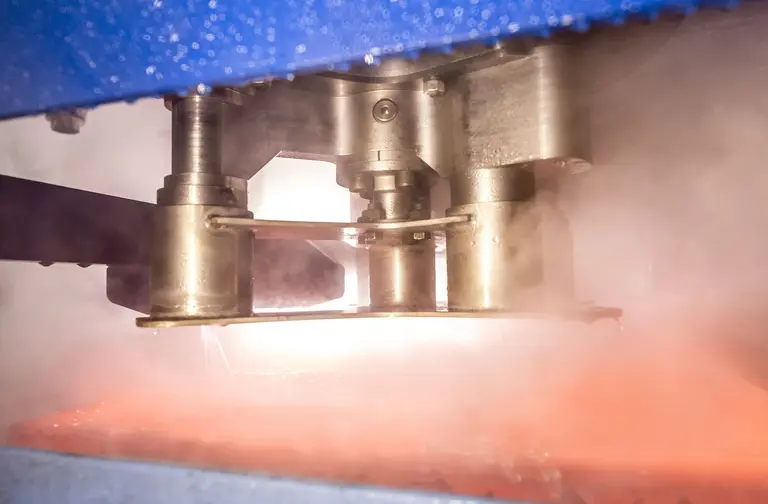

In the subsequent year, 2021, finishing mill stands F5 to F7 were upgraded with the latest generation CVC® plus work roll shifting system, replacing the older system.

Following these systematic mechatronic modernizations in recent years, Salzgitter now relies on state-of-the-art control systems and process models from the X-Pact® product family. In 2022, SMS group was commissioned to deliver an advanced process model for the cooling section with fully automatic operation.

At of the end of 2023, Salzgitter Flachstahl GmbH has awarded SMS group a contract to supply a comprehensive technology package for the hot strip mill in Salzgitter. This package includes an array of new functions and a harmonized tool environment, operated on the most advanced automation platforms. Additionally, the scope of supply features the X-Pact® Integrated Temperature Model, a learning, self-optimizing process control feature, as well as the integrated strip guiding control system, known as X-Pact® Centerline Control. These process models ensure high process stability and safety in the hot strip mill, making a significant contribution to more sustainable, profitable, and self-optimizing plant operations.

Conclusion

Thanks to the strategic partnership with SMS group, the HSM of Salzgitter Flachstahl GmbH does not need to shy away from comparison with younger plants even after more than 60 years of operation. Rolling highly demanding grades while adhering to the strictest tolerances specified by the customers is no problem for the HSM. We are proud to be the Lifecycle Partner of Salzgitter Flachstahl GmbH to contribute to the continuous further development of the HSM and to keep the facility fit for the future.