Investment in our future

Lightness.NRW – Developing materials and processes for the utilization of recyclable, eco-friendly, and maximum-strength aluminum alloys in mass-producible, ultra-lightweight designs for future mobility.

Summary

For many different reasons the automotive industry is under immense pressure - in both the short and medium term - to design and build vehicles that are significantly lighter.

That is why aluminum producers are sparing no effort in the development of new, high-strength aluminum alloys, and have set their sights on winning major orders in future with these kinds of alloys as a competitor to steel. In terms of high-strength aluminum alloys, however, one drawback that must be taken into consideration in the vehicle design is the lack of cost-effective manufacturing technology that is not only adapted to such high-strength alloys but is also suitable for large-scale production. The huge benefits to society that this brings are found not in the developments that can only be implemented for top range vehicles; rather, what’s needed are lightweight systems that can be utilized in all vehicle segments.

The resulting project consortium is purposefully set up in such a way that all the requisite development stages, including a new, patentable production technology, are covered by reputable global players: that goes for everything from the development of the high-strength, process-adapted aluminum alloys, right up to the design of the components and construction of the manufacturing facility required for it – e.g. in this case, for the first time, for the Ford Fiesta developed and built in Cologne.

Suppliers in NRW (e.g. from the Attendorn region) are also able to benefit from the development of this mass-producible lightweight technology for the new high-strength aluminum alloys by designing and offering other products with these alloys.

Runtime

June 1, 2018 to June 30, 2021

SMS group GmbH is coordinating this joint research project, which is being funded and promoted as part of the “New Materials” lead market competition.

Results

As part of the Lightness.NRW project, a hot die forming (HDF) process was developed that allows high-strength and maximum-strength aluminum alloys – as sheet metal or tubular semi-finished products – to be formed into ultra-lightweight structural components with highly complex geometries. The potential of HDF technology for lightweight structures in large-scale vehicle production was demonstrated by means of laboratory and demonstrator components and component studies. In order to utilize the full technological potential with regard to ultra-lightweight structures, a process simulation and a component simulation for static and dynamic applications that is based on experimental results were also developed.

-

Project consortium answers complex questions

-

Project consortium answers complex questions

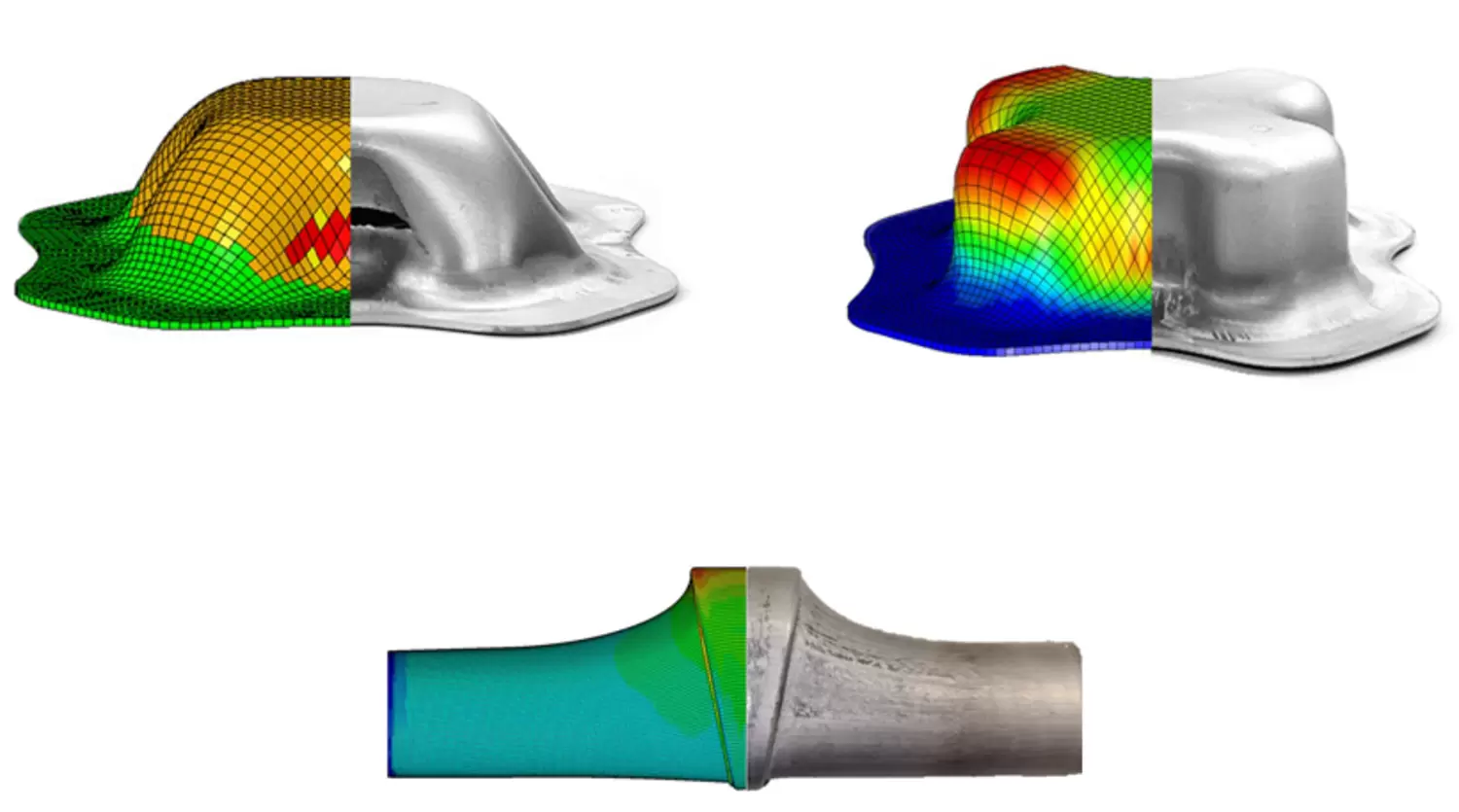

Only the comprehensive project sonsortium, set up to cover all aspects of the value chain, was able to answer the complex questions that arise along the whole process chain. The capabilities and competencies of the consortium partners range from the development of alloys, processes and equipment, through the establishment of an accompanying simulation methodology for describing the forming process and component behavior, right up to the development and production of real demonstrators and their final experimental characterization. Based on the development and selection of a high-strength aluminum alloy that is suitable for HDF technology, the performance of the innovative forming technology for producing complex aluminum structural components was demonstrated and experimentally validated by the successful manufacture of two technology demonstrators – crossmatch and tube node.

This process was backed up by FE-based process and component simulations in order to achieve a gradual optimization of the tool and component geometry. Based on the calculated mechanical characteristics (static and dynamic), a material card was developed that enables the targeted design and dimensioning of aluminum lightweight structures.

Consequently, this resulted in the development and validation of a powerful CAE simulation methodology as well as a material card and material database that can also be used outside of the project. Using the results of the experimental tests and the findings gained from the manufacturing process of the demonstrator components with regard to the maximum degree of deformation, design guidelines and thus potential applications in the automotive sector could also be elaborated.

![]()

-

Potential of HDF technology

-

Potential of HDF technology

A large number of static and dynamic tests on the technology demonstrator components served as a reliable data basis for assessing the potential of HDF technology. The effects of post-treatment on the component properties were also examined by means of simulations and experiments, in order to ensure optimized heat treatment to achieve the desired mechanical component properties.

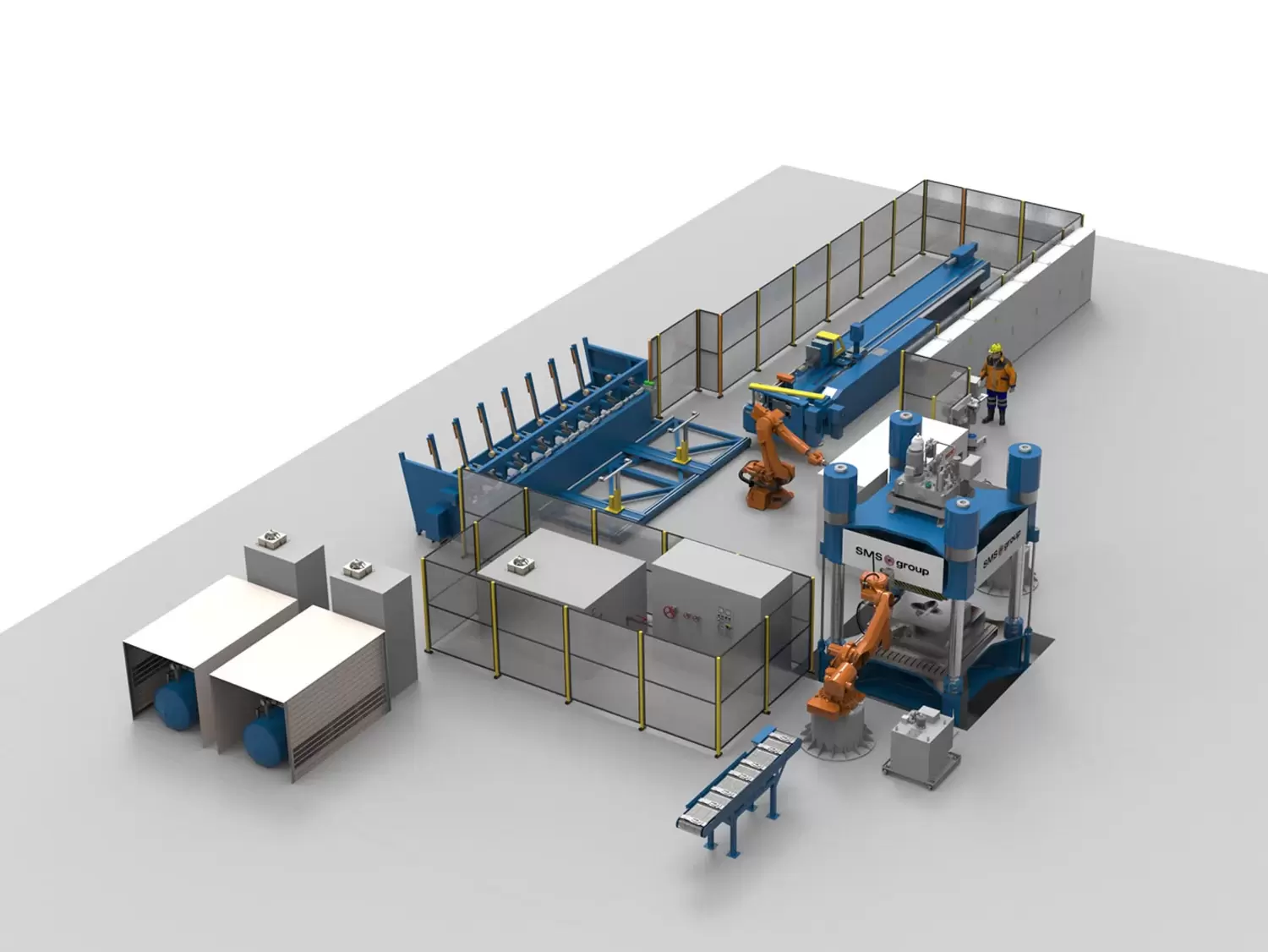

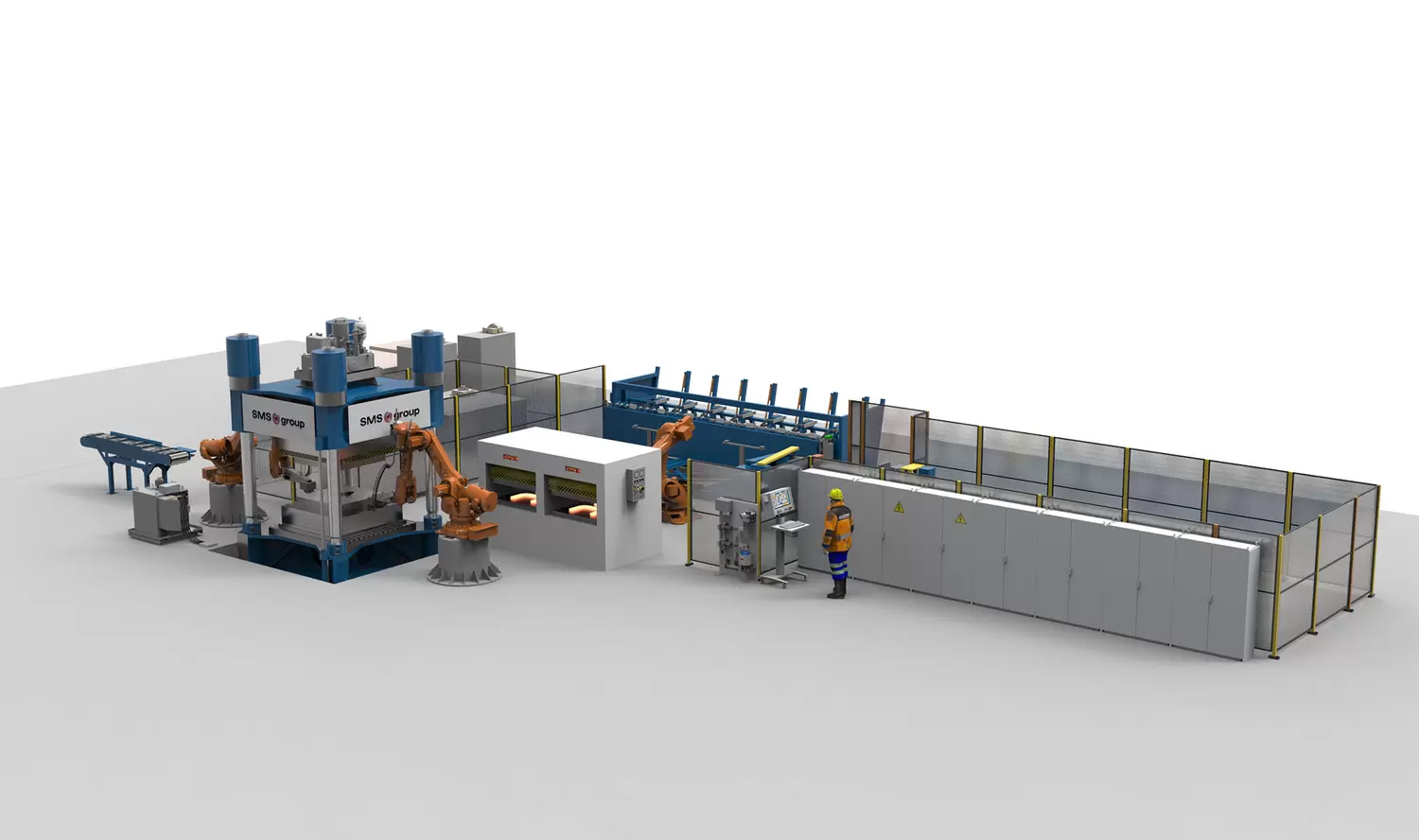

The design of a plant concept for the integration of HDF technology into a large-scale production environment constitutes the successful completion of an important step within the project from laboratory scale to series production. For this purpose, a process facility, including all equipment, preparation and supply units, and associated handling systems, was virtually realized using the example of the manufactured tube node, taking into account cycle times in the large-scale series production of vehicles. Based on this virtual representation of the overall facility, it was possible to evaluate the manufacturing costs and the environmental balance, and to determine general suitability for large-scale series production with the assistance of the end user from the automotive industry.

In this way, the foundation has been laid for the establishment of HDF technology in large-scale production applications. This is supported by the final evaluation of the component characteristics achieved, which show that HDF technology represents a great opportunity for energy- and resource-efficient lightweight construction. In the years to come, this technology can make a major contribution to ensuring that complex (structural) components, made of high-strength aluminum alloys, that cannot be manufactured cost-effectively, if indeed at all, can be widely used in series production and thus enable ultra-lightweight metal construction.

![]()

Downloads

Contact

-

Koos van Putten

-

Koos van Putten

Research & Development

+49 2161 350 2434SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Germany![]()

This project is funded by the European Union and the state of North Rhine-Westphalia.