With this integrated plant, Wuhan Iron & Steel is able to produce high quality strip and thin plate products with an capacity of 400,000 t/year. The comprehensive know-how, proven technology and commissioning competence were decisive factors behind the customer's choice of SMS group as partner for this strategic project.

SMS group’s first CCSL for cutting thin ultra high-strength steel plates

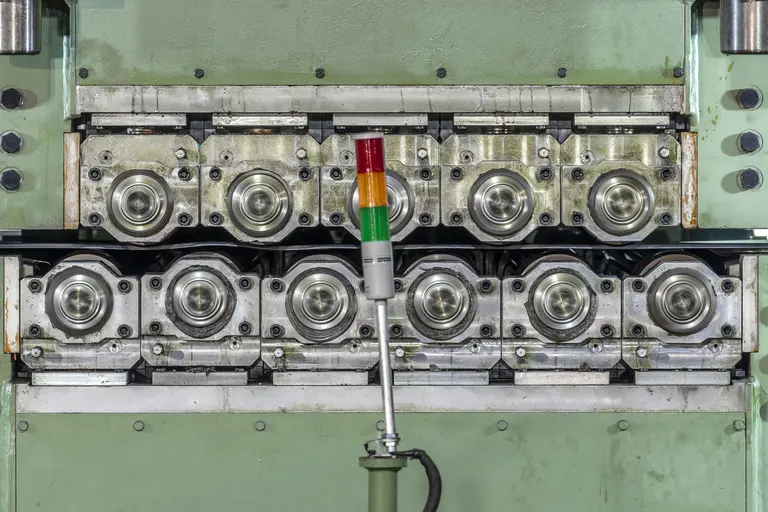

SMS group has delivered a cross cut shearing line specifically designed for the production of ultra high-strength thin steel plates consisting of complete mechanical and electrical equipment, advanced automation and the process technology. This CCSL is capable of processing steel coils with strip thicknesses ranging from 2 mm to 12.7 mm and yield strength limits of up to 1,300 MPa. The leveler is a key component of the CCSL. To meet stringent product specifications, SMS group has engineered the double-roller cassette technology for the levelling machine. The double-roller cassette features either a 15-levelling roller box with a diameter of 100 mm or a 11-levelling roller box with a diameter of 180 mm.

The breakthrough innovation of the leveler is the fast roll change technology, which is based on the retaining of the unique single-roll adjustment. The automatic roll change of different roll diameter roller cassettes can be completed within in 20 minutes. By this, not only the leveling range is expanded, but also the utilization of the production line is significantly improved.

Beside the double-roller cassette, the leveler is also equipped with single-roller drive technology, which does not only improve the control level and the leveling effect, but also the energy utilization rate, so that the energy consumption per ton of steel is considerably reduced.

At the same time, the leveler comes with X-Pact® automation, comprising a full hydraulic roll gap control system, bending roll compensation system, single roll adjustment system, torque balance control system, multi-strategy leveling model and other control systems, all ensuring high-quality steel plate with excellent flatness and stable residual stress.

Cutting edge technologies

In general, handling of coils with excessive yield strength is not without risk for the operating personnel. SMS group also has a solution for this problem. The anti-loose coil feeding system for high-strength steel coils provides maximum occupational safety in coil handling, because the risks of loose coil ends and falling of coils from the transportation saddle are completely avoided.

Another solution is the targeted multi-strategy centering technology, effecting the precise centering of the steel strip. By this, the problem of thin strip centering and curling is avoided and thereby the yield of the production line is improved.

The leveler is provided with continuous leveling technology, which is further development of the single-plate leveling technology. Continuous leveling technology is more suitable for the leveling of thin steel strips.

The flying shear with upper and lower blades cutting at the same time, shear deformation of the strip is effectively reduced. Especially the quality of the head and tail of the finished plate is improved.

The new stacker increases the supporting surface of the plate, which can avoid the disordered fall of the wide and thin plate due to the deformation of its own weight, and improve the quality of the plate and the overall stacking accuracy.

The multi-segment chain plate transfer system effectively solves the problem of interlacing and scratching during the transfer of thin steel plate stacks and ensures the surface quality of the plate.

Wuhan Iron & Steel is very satisfied with the effective implementation of the above technologies.

X-Pact® Process Automation Control Technology

In order to ensure high line efficiency and excellent, stable product quality, SMS has delivered advanced automation and control technologies. X-Pact® Mathematical Model calculates the roll positions, speed and torque of the levelling rolls and controls the process to release the residual stress in the plates. Based on yield strength, modulus of elasticity, incoming material dimensions, target thickness and initial flatness defects, the high precision elastoplastic leveling process model ensures the right setup of the leveler.

The precise position control for the levelling rolls is realized by high precision sensor and high response controller. At the same time, the speed and load control of the levelling rollers also require the transmission system to be equipped with fast response closed-loop vector control and dynamic load distribution control. The above technology ensures the excellent and stable quality of the plate flatness.

X‑Pact® Flying Shear Control, based on a servo drive system and high‑speed controllers, accurately calculates strip position and rapidly coordinates multiple devices to achieve precise cutting and strict length tolerances for the finished plates. Optimized roller-speed strategies and material tracking enable efficient and precise transfer of the plates to the stacker. With the help of X-Pact® Stacking System Control, stacking efficiency is ensured and incoming plates are precisely piled.

The stable sequence control and X-Pact® Vision HMI interface help the operator to comprehensively monitor the production line and adjust production parameters at any time.

Heat treatment leveler of thin ultra high-strength steel plates

SMS group's second premiere for Wuhan Iron & Steel is the heat treatment leveler for the production of ultra high-strength thin steel plates. The leveler is an essential part of Wisco’s heat treatment line. It is capable to produce ultra high-strength heat-treated thin steel plates with limit specifications of 3mm and more than 1,500 MPa, and up to 9 mm with a strength of 800 MPa.

The leveling of heat treated ultra-high strength steel plate mainly overcomes several technical challenges. There is a sufficient large deformation rate of the plates being provided by application of large leveling forces. Finite element calculations are used to check the stress level as well as to define the right diameter of leveling rollers and backup rollers.

The SMS technical team customized the backup roll bearings for this project, which perfectly meets the customer requirements and design expectations.

SMS group’s innovative design of the leveler’s drive system features a two-stage system, considering cardan shafts and gear spindles providing a torque of 10,000 Nm at the single roller.

Further, the leveler is equipped with hydraulic roll gap control, bending roll compensation system, single roll adjustment system, torque balance system control system, multi-strategy leveling model control system and other control systems to ensure high quality plates with excellent flatness and stable residual stress.