The example of the use case taken from developments in cold rolling relates firstly to continuous pickling line/tandem cold rolling mills and is aimed at optimizing them with fully automatic technology. The range of available options include improving production planning or navigation-based process control for the operator. Here, the so-called product changes, the most challenging point in the continuous rolling process, were chosen first for optimization. With continuous rolling mills, endless strip is rolled, therefore when there is a strip change the mill does not stop, but rather it moves through the change normally at reduced rolling speed under rolling force and, in most cases, full reduction.

The challenges of strip and product changes during continuous rolling are the rapid shifts in the operating points. These are caused by an almost abrupt change in the strip properties and strip dimensions in the individual mill stands. Such changes, especially the significant ones, must be targeted as precisely as possible in order to ensure the plant‘s stability while at the same time satisfying the high demands regarding product quality parameters and productivity. Typical quality parameters include the strip flatness and the strip thickness tolerance. Therefore, the plant operator needs the greatest possible flexibility when selecting the product changes while at the same time ensuring stable rolling processes with high product quality.

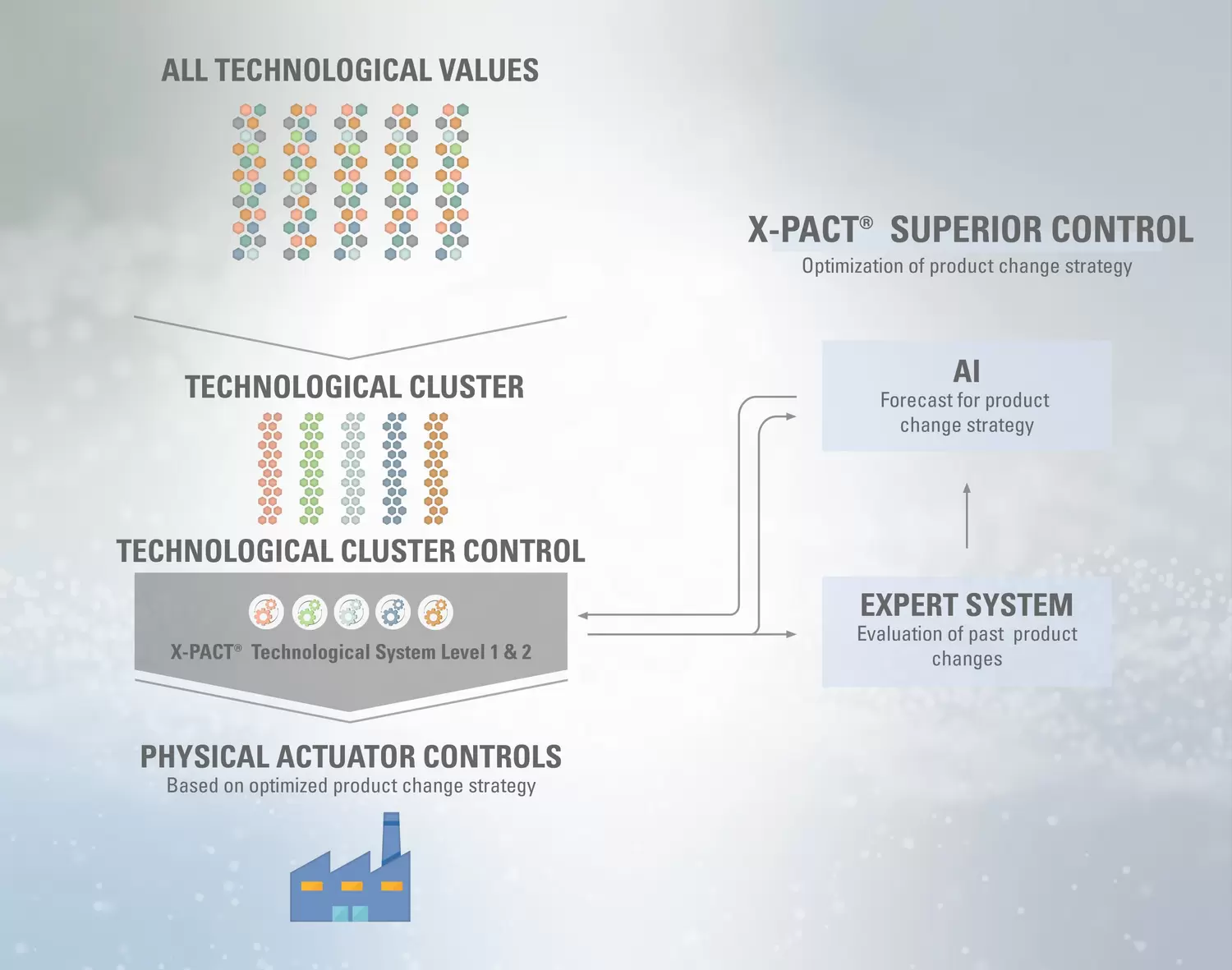

The entire automation system with all its setting options, for example manual operator interventions and the technological control systems (level 1) right up to the pass schedules from the physical process models (level 2), are divided into so-called technology clusters. These technology clusters correspond to the final product quality criteria. As such, there are technology categories for the strip flatness and strip thickness, among other things. Contrary to the current state of the art, the automation system therefore no longer operates with individual values, such as a manual bending change, or an additional value for CVC® shifting from the flatness control system. With this new approach, the clusters are organized centrally according to their technological allocation and are controlled by it.

Roadmap towards the learning tandem mill

The advantage of this step beyond the limits of the level 1 and level 2 systems is that interlinked and separately runnable structures can be mapped. In concrete terms, this means that unlike the current state of the art, the automation system does not require a fixed differentiation between the level 1 and level 2 systems. Both systems work in a closely connected and coordinated manner, thereby opening up a multitude of new technological possibilities.

The next step on the road to the Learning Tandem Mill is to take large amounts of data to develop an artificial intelligence that can take over higher-level control, i.e. over the technology clusters.

The basic idea behind this is: If a technologist can clearly find out from the data what technological mode of operation would have been the most expedient for a given product change, then this can also be calculated. The largely good accessibility of the available data means that this calculation can be done independently of the choice of technological strategy.

In this way, an expert system is developed as part of X-Pact® Superior Control, which automatically calculates the optimum strategy for all product changes, i.e. the optimum combined method of operation from the technology clusters such as flatness, thickness, etc. This expert system provides so-called „labels“, data that subsequently indicate the optimal strategy for a product change that has already been carried out. This look back at the past can now be done as often as needed based on mass data. The next step, therefore, is to supply digital AI systems that are used to provide a forecast for the optimal product change strategy.

As soon as the artificial intelligence provides a sufficient hit rate in its prediction, it generates added value in the form of an improved off-gauge length for strip flatness and thickness and increased product change stability. This is because the proposed strategy from the digital AI system can directly be coupled to the control of the technology clusters of level 1 and level 2 systems. Using mass data as a basis, these AI systems provide optimized strategies for level 1 and level 2 systems and implement the presets in real time for strip changes. The objective is thus to create a technologically self-optimizing plant that continuously enhances its product quality over its whole life cycle.