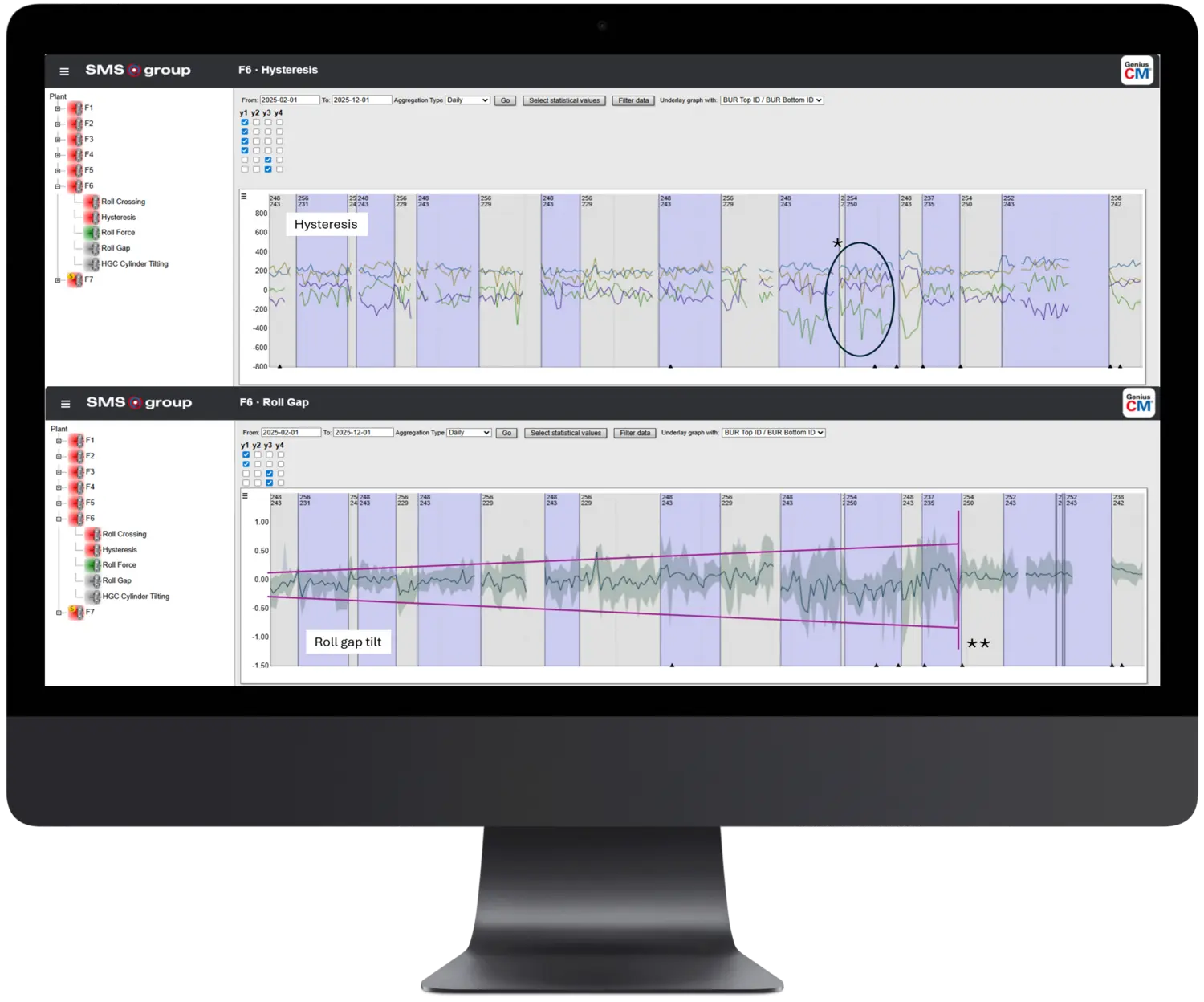

The process begins with conventional condition monitoring, which continuously monitors roll forces, roll crossing (axial forces) and hysteresis, producing statistical KPIs and alarms that identify where the mill is deviating from acceptable behavior. The system leverages existing automation data and model‑based calculations to provide actionable outputs. This proactive monitoring serves as an early warning system, allowing for the identification of potential issues before they escalate.

* service requested due to increasing rolling stability issues

** change of hydraulic cylinders and reworking of surfaces

The alignment deep dive

Where conventional condition monitoring identifies negative trends, the Mill Stand Assessment delivers an in-depth analysis to identify root causes. The solution evaluates mill stands alignment, CVC® block and chock geometry and combines mill stand and chock measurements to identify the true cross‑angle between backup‑ and work roll middle axes. Because excessive cross‑angles generate unacceptable axial forces, accelerate component wear and impair CVC® shifting and strip steering, quantifying the real cross‑angle is critical to preventing further damage. The outcome is a holistic diagnosis that reconciles roll shop and mechanical views and clarifies which chock combinations or housing misalignments drive the observed effects.

From analysis to service: a clear, prioritized action plan

Based on these findings, SMS teams from X-Roll® Service deliver a tailored, prioritized action plan specifying required refurbishments, execution steps and expected benefits. Typical service outcomes include continuous chock fleet management with systematic refurbishment and preventive maintenance, precision mill housing realignment and mechanical refurbishment as needed, and low-effort interventions to compensate for residual misalignment. This process also identifies upgrade or spares needs, such as CVC® refurbishments, pusher cylinder improvements, or stainless-steel steps for backup roll sleds, ensuring that investments are targeted and justified. SMS presents what must be done, why, and how, enabling plant managers to avoid unnecessary maintenance and hidden negative trends.

By combining monitoring intelligence with on-site assessment and targeted service execution, SMS helps customers unlock their plants’ true performance - converting ambiguous symptoms into clear, cost-effective actions that drive operational excellence.