High-quality metal plants and services for the aviation industry!

SMS group is a globally leading supplier of plants, machinery, and technologies for the steel, aluminum, and copper industry. Our innovative solutions play a crucial role in the aviation value chain, as they enable highly precise materials and components that are indispensable for this demanding sector. In addition high-level performance is ensured over time through comprehensive service support.

Plant technology and services for high-quality aviation parts production

Even though composite materials are increasingly used in aircraft construction, approximately 40 percent of all components in an aircraft are made of metal. For instance, a current Airbus A350 consists of 19 percent aluminum, 14 percent titanium, and 6 percent steel. Typical applications of forged parts include turbine blades and engine shafts. Flat products, such as those made from aluminum, are widely used in the fuselage or wings. Extruded components are also found in many areas of aircraft, such as overhead compartments and seat rails. All these products can be manufactured with the highest quality and efficiency using SMS group plants and machinery.

Forged parts and extrusions

-

Closed-die forging presses

-

Closed-die forging presses

Closed-die forging presses play a central role in the manufacturing of components for the aerospace industry, particularly in the production of high-precision, durable, and complex-shaped parts. Under high pressure, metals are placed into a predefined mold (the die) and compressed.

Applications:

- Turbine blades

- Engine shafts

Highly stressed structural components.

-

Ring rolling machines

-

Ring rolling machines

Ring rolling machines shape solid metal blanks (often made of aluminum, titanium, or nickel-based alloys) into seamless rings through plastic deformation. These rings have no weld seams or joints, which enhances their mechanical integrity and load-bearing capacity. The machines enable the production of rings with precise dimensions (outer and inner diameter, wall thickness, height) and tight tolerances, meeting the demanding requirements of the aerospace industry.

Applications:

- Turbine rings: Turbine housings and compressors, where they must withstand extreme temperatures and mechanical stresses.

- Flanges and sealing rings: Connection and sealing of engine components

- Wing connections: Connecting or reinforcement elements in wing structures to reduce weight while ensuring high strength.

- Fuselage components: Reinforcement rings or frames in aircraft fuselages.

- Rocket and satellite structures: Launch vehicles and satellite structures, where low weight and high load-bearing capacity are critical.

- Fuel tanks and pressure vessels: Pressure vessels and tanks designed to withstand extreme pressure and temperature conditions.

-

Extrusion presses

-

Extrusion presses

In the aerospace industry, extrusion plays a crucial role by enabling the production of lightweight, thin-walled, and highly durable components that meet the stringent requirements of the sector. SMS group's extrusion technologies are designed to efficiently process materials such as aluminum and titanium, delivering precise components for critical applications.

Applications:

- Overhead compartments: Aluminum extrusion profiles are used for the structure of overhead compartments in aircraft due to their light weight and stability.

- Seat rails: Aluminum extrusion profiles provide stability and safety for seat rails while minimizing weight.

- Radar components: Extrusion profiles are used for the housings and mounts of radar systems, offering high precision and electromagnetic compatibility.

- Instruments and lighting: Aluminum profiles offer an ideal combination of lightness and design flexibility for the housings of instrument and lighting systems.

- Pressure-loaded lines: Seamless tubes are used in brake systems and hydraulic lines because they can withstand high pressure and extreme conditions.

- Fuel lines: Seamless aluminum or titanium tubes are employed in fuel systems for their corrosion resistance and reliability.

- Airflow systems: Extrusion-produced tubes are used for airflow in cabins and engines, where lightness and precision are crucial.

-

Service for forging plants

-

Service for forging plants

Coupled with mechanical expertise, our comprehensive service packages for forging plants cover the entire lifecycle of all our plant components, guaranteeing high availability for plant equipment. These packages enhance customer value by minimizing unplanned production issues with SMS equipment.

Our technical solutions extend beyond mere repair and modernization, core components, and spare parts. They deliver a multitude of benefits to customers, streamlining operations and bolstering the bottom line. Long-term contracts expedite repair times and spare part provisioning through SMS group's dedicated in-house spare parts inventory, ensuring maximum flexibility.

Our automation and digital solutions enable the consolidation of data from various aspects of equipment automation and software. This integration offers a comprehensive overview of equipment and process conditions, quality management, production planning, and energy management.

Flat products

-

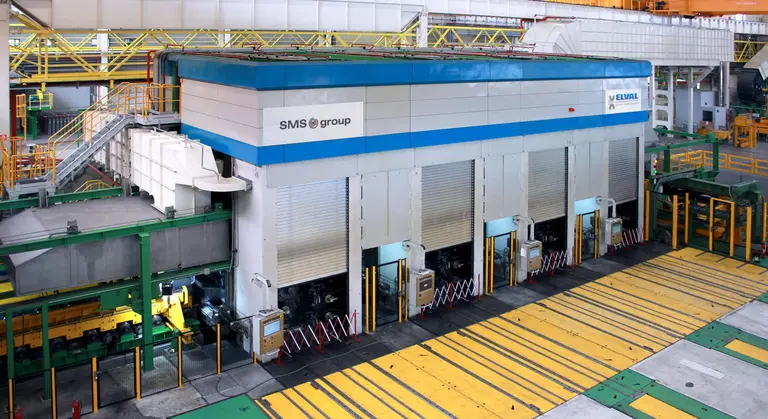

Ingot scalper

-

Ingot scalper

An ingot scalper processes large and heavy aluminum ingots that come from casting, removing surface inclusions and cracks. Simultaneously, the ingot is milled to be flat and parallel, providing a geometrically clean semi-finished product for hot rolling.

-

Rolling mills for aluminum

-

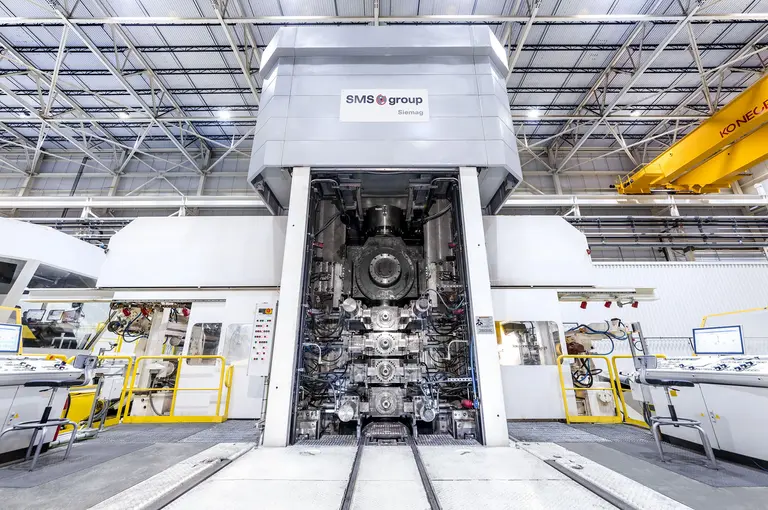

Rolling mills for aluminum

Hot and cold rolling mills are the core machines for the production of aluminum strips. Their primary purpose is to transform aluminum blocks or ingots (semi-finished products) into thin, uniform strips through plastic deformation. In the process, the mechanical properties, surface quality, and dimensions of the material are precisely adjusted to meet the requirements for subsequent processing steps or final applications.

-

Plate stretcher

-

Plate stretcher

In the production of aluminum plates, such as those used in aircraft construction, thermal stresses develop in the material during rolling and subsequent heat treatments. The stretching process helps to relieve these stresses and prevents cracks or deformations during subsequent machining steps.

The plate stretcher operates using a combination of high pressing forces and precise control. Aluminum plates, up to 300 mm thick, are clamped between two or more grippers. The machine applies a controlled tensile force, stretching and plastically deforming the material. During stretching, the plate can be stretched not only in the longitudinal direction but also vertically using cross-leveling presses, which help reduce transverse warping in the plate.

-

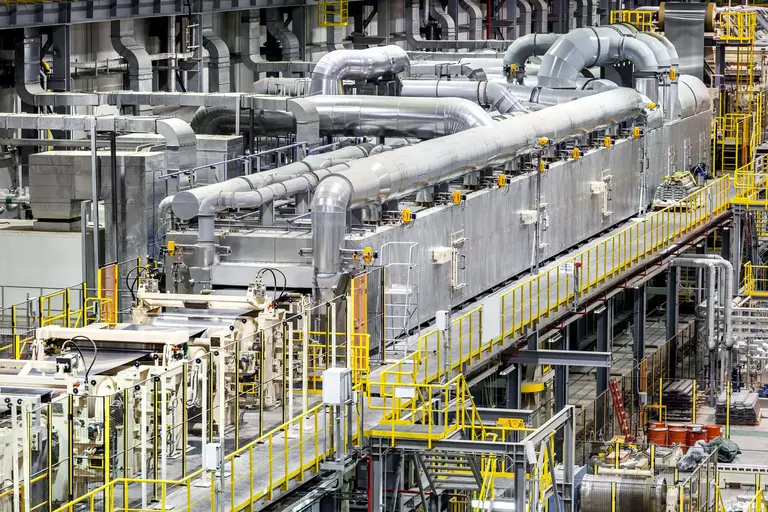

Processing lines for aluminum strip

-

Processing lines for aluminum strip

Annealing furnaces play a crucial role in the production and processing of aluminum strips. They are used to specifically influence the mechanical and microstructural properties of the material to meet the requirements for further processing and final applications. Through precise temperature control and holding times, the hardness and strength of the aluminum strip can be adjusted. Annealing ensures that the aluminum strip possesses the necessary properties for subsequent processing steps, such as deep drawing, stamping, coating, or painting.

Metallurgical plants

-

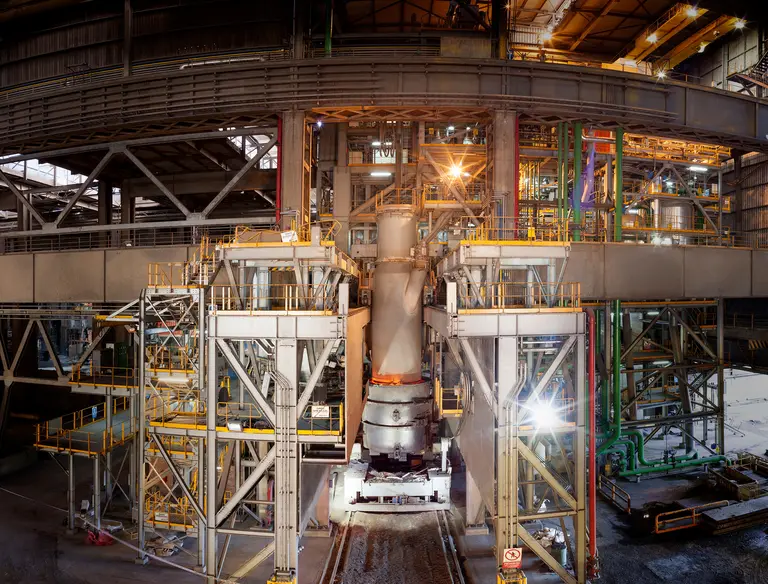

Secondary metallurgy

-

Secondary metallurgy

Secondary metallurgical plants are employed in steel production after the primary melting process to specifically enhance the quality of the metal melt. In aviation manufacturing, they play a crucial role, as the components produced must meet stringent requirements for purity, mechanical properties, chemical composition, and microstructure. Secondary metallurgical processes enable the production of high-quality alloys and materials that are indispensable for demanding applications in this sector.

These facilities remove undesirable elements such as sulfur, phosphorus, oxygen, nitrogen, and hydrogen, which can negatively affect the mechanical properties and corrosion resistance of the alloy. This is particularly important for materials like titanium and nickel-based alloys, which are commonly used in aviation applications.

-

Powder atomization plants

-

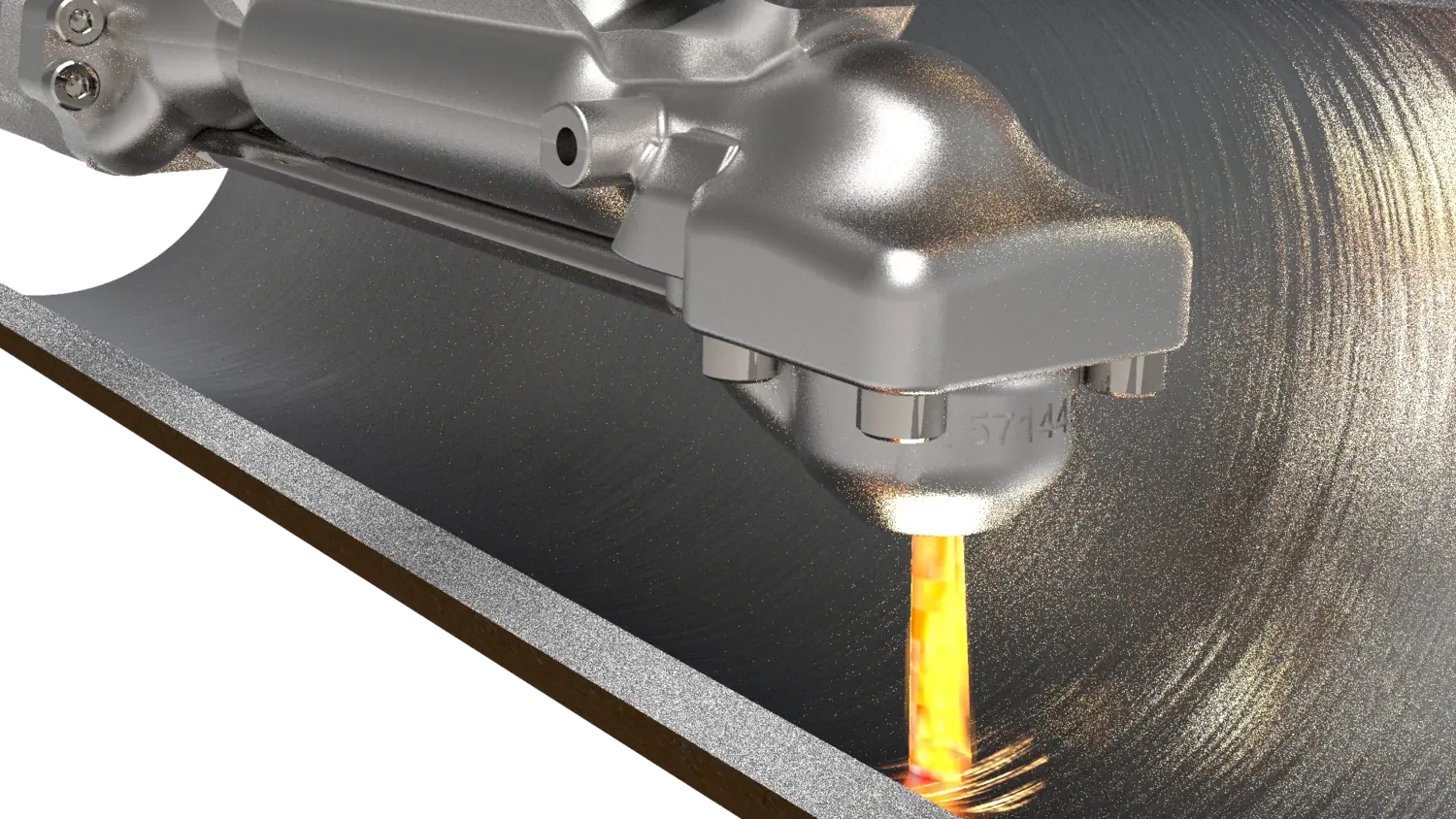

Powder atomization plants

SMS group's powder atomization plants are specifically designed to produce metal powders with precise particle properties that meet the high demands of additive manufacturing and the stringent quality standards of the aerospace industry. The powders produced serve as the starting material for the fabrication of complex, lightweight, and highly durable components.

Powder atomization plants ensure that the manufactured metal powder is free from impurities, oxides, or inclusions. This is crucial because even the smallest impurities can adversely affect the mechanical properties and safety of aerospace components. These facilities generate metal powders with precisely adjustable particle sizes, typically ranging from 15 to 63 µm for 3D printing. Uniform particle size is essential for optimal layer formation in the additive manufacturing process.

Applications:

- Engine components: Manufacturing turbine blades, compressor wheels, and housings from nickel-based or titanium alloys that must withstand extreme temperatures and mechanical stresses.

- Structural components: Production of lightweight components such as brackets, stiffeners, and frames made from aluminum or titanium alloys, which reduce weight while providing high strength.

- Space applications: Fabrication of fuel tanks, pressure vessels, and structural components for satellites and rockets, requiring low weight and high load-bearing capacity.

Innovating aviation

Thermal coatings

Thermal coatings protect landing gear components from corrosion and abrasion – especially on the inside. Our HVOF coatings cover an inner diameter range of 60 to 100 mm.

E-fuels

SMS group has been contracted to engineer and design one of the world’s first industrial-scale e-fuel production sites for Norsk e-Fuel located in Mosjøen, Norway.

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.