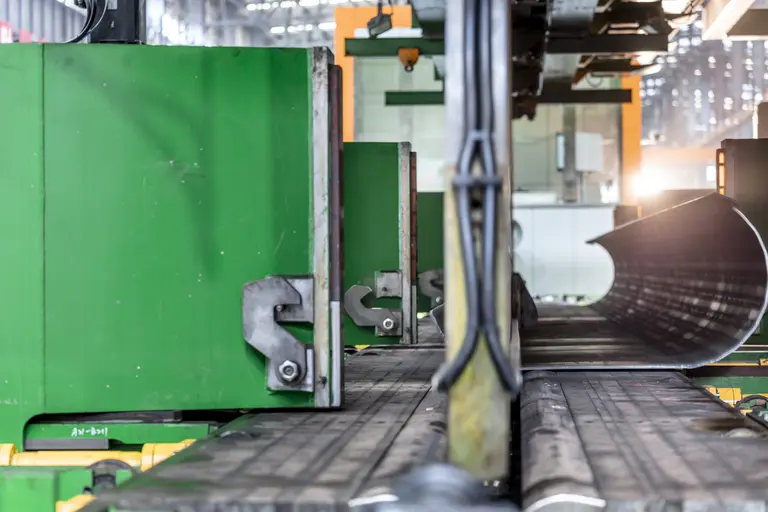

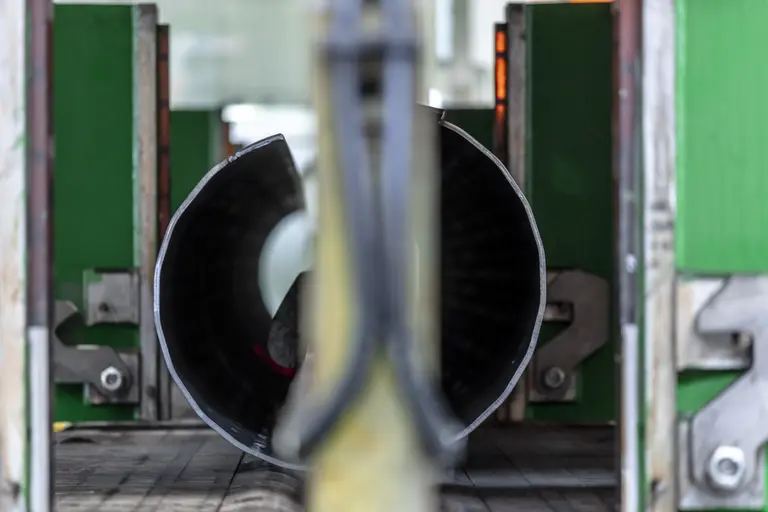

JCO成型机

经济高效的成型工艺,低碳排放

主要数据在直缝埋弧焊管生产中,有三种主要的成形工艺,我们重点介绍 JCO 工艺。与其他工艺方法相比,这种工艺不仅非常灵活,而且投资较低。因此,在 西马克 集团开发该工艺后,它很快就在市场上确立了主流工艺的地位。

该工艺非常适合中小型生产能力,并能实现灵活生产,可高质量地生产从常规尺寸到高难度尺寸的管材;同时也可以实现高产能(年产50万 吨以上)。由于采用了 VSP(变速泵)液压系统,JCO 成型机和合缝机的组合实现了低碳经济和生态生产。

Three main forming processes have become established in LSAW tube production. We focus on the JCO process. This method is not only very flexible, it also requires lower investment compared to other methods. Therefore, it has quickly established itself on the market after its development by SMS group.

The process perfectly fits small and medium-sized production capacities and enables flexible production, covering regular up to very challenging pipe dimensions at high quality. But also high capacity plants (500,000+ tpa) can be realized. Thanks to the VSP (Variable Speed Pumps) hydraulic system, the JCO pipe forming press along with the crimping process offer economic and ecologic production with a low carbon footprint.