Steel producers are facing increasing pressure to balance growing infrastructure demands with sustainability goals. As a full-system provider, SMS group delivers tailored solutions that incorporate practical innovations to enable the efficient production of straight bars, compact coils, and wire rods for construction and infrastructure development.

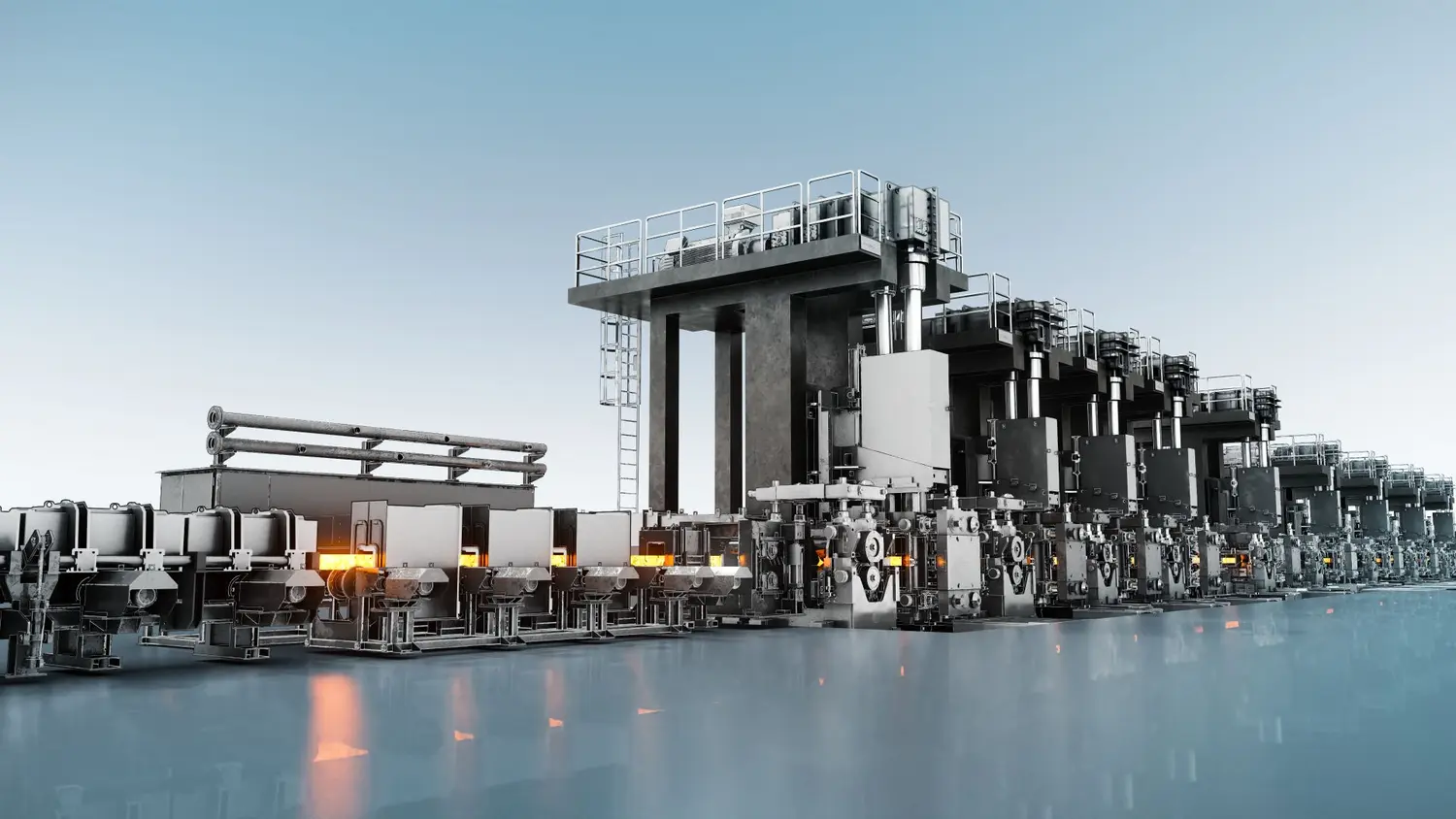

Our continuous minimill technology (CMT®) creates an energy-efficient production system by integrating three processes: steelmaking, casting, and rolling. The process begins with scrap metal charged into an electric arc furnace (EAF) for melting and refining. The liquid steel feeds directly into a high-speed caster that connects to the rolling mill, eliminating the need for conventional fossil fuel-fired reheating furnaces.

We engineered the CMT® minimill to maximize production capability while minimizing the installation footprint. This space-efficient design has dual advantages: lower initial investment costs and reduced operational expenses throughout the plant’s lifecycle.

CMT® produces a comprehensive range of products, from straight rebars to vertical compact coils (VCC) weighing up to 8 t. Our integrated X-Pact® automation solutions coordinate every production aspect – from scrap yard logistics to finishing area operations – while managing maintenance schedules to enhance productivity and control costs.

Technology

Low-emission steelmaking

The AllCharge technology employed at the beginning of the CMT® process combines continuous scrap charging with flat bath operation, eliminating furnace roof openings during production. This design decouples off-gas extraction from scrap conveying, significantly reducing CO2 emissions while improving control of pollutants such as NOx and VOCs.

Closed-roof flat bath operation delivers significant electrical savings and maintains higher off-gas temperatures, enhancing emission control quality. AllCharge also minimizes water and refractory consumption, reducing maintenance requirements and operating costs. Integration with our X-Pact automation platform ensures precise material flow tracking and immediate anomaly detection throughout the process.

High-speed continuous casting

Precise synchronization is essential in combined casting and rolling operations. The tundish slide gate control system maintains optimal steel flow and mold level stability. We employ specialized entry shrouds and lubricating powder to enable uninterrupted high-speed submerged casting.

Our Conrex mold technology addresses the increased heat loads associated with high-speed casting. This advanced system optimizes cooling, reduces thermal stress, and maintains lower operating temperatures. Its design minimizes the containment length while reducing roll wear. Grooves on the mold tube enhance heat transfer for improved cooling efficiency. The Condrive system ensures precise mold oscillation through torque drive technology, allowing real-time adjustments while reducing operational costs compared to conventional hydraulic systems.

Ultra-flexible rolling mill

The CMT® rolling mill operates continuously, with the cast strand running directly into the mill. We position an induction heater before the mill to provide supplementary heating or temperature equalization when required. The rolling line accommodates both deformed bar production and VCC coil winding within the same product range.

The system produces straight bars from 8 to 63 mm and wound bars from 6.3 to 32 mm. With additional equipment, it also handles wire rod from 5.5 to 26 mm (28 mm) and light sections, delivering maximum operational flexibility and production versatility.

The CMT® rebar mill features our eight-pass MEERdrive high-speed finishing block, which delivers substantial energy savings. This technology reduces roll ring inventory by 60% compared to conventional finishing blocks through flexible gear ratio selection.

The individual drive concept lowers energy consumption and operating costs by approximately 30%. Our MEERarms ring-changing system enables module changes in just ten minutes, further improving operational efficiency. The “one-family-rolling” concept sequence optimizes production, reducing both downtime and energy usage.

Comprehensive automation

Our X-Pact® automation system provides comprehensive control across the entire plant from level 2 to level 0. This integration ensures seamless coordination between melting, refining, casting, and rolling processes and offers advanced system tools for production planning, scheduling, and optimization.

Built-in business intelligence capabilities deliver detailed statistical analysis and product certification to facilitate data-driven decision-making throughout the process.

Sustainable by design

From its conception, we engineered CMT® to minimize energy consumption and the carbon footprint. The system delivers proven sustainability benefits for the entire production process. Our innovative EAF technology significantly reduces the carbon footprint of steel production. Advanced power electronics minimize fossil fuel usage, electrode consumption, and electrical energy requirements during the melting process.

The X-Pact® Lights-Out concept moves operations toward autonomy, improving efficiency and safety while reducing emissions. Innovations like the Condoor® automatic slag door and X-Pact® Sampler automate slag removal and ensure precise sampling for optimal charge mixes, thereby enhancing performance. These technologies contribute directly to decarbonization by saving energy and improving carbon and lime injection yield, resulting in measurably lower CO2 emissions.

We equip DC EAF technology with our X-Pact® AURA digital power-feeding system. This combination of modular electrical panels and state-of-the-art electronics ensures high efficiency and power density with minimal grid impact. Key advantages include:

- Reduced power losses

- Enhanced electric arc regulation through fast control power electronics

- Improved arc stability for consistent operation

- Minimized network disturbances even on weak power lines

- Enhanced reliability thanks to our one module full redundancy concept

A dedicated water treatment plant is integral to the CMT® process. This facility employs advanced technologies that reduce water consumption and eliminate discharge – achieving a 70% reduction in make-up water requirements and a 100% reduction in process water discharge.