The continuous development of bearing technologies with emphasis on operational representativeness, durability, and cost efficiency is one of the core competencies of SMS. The in‑house test rig establishes qualification metrics for prototypes and series components. Results yield reproducible parameters for load‑carrying capacity, lubricant‑film stability, thermal behavior and pressure‑side responses to load transients, enabling reliable assessments of service life and leakage performance

Originally, SMS oil film bearings were based on technology from the Morgan Construction Company (USA) and were used under licensing agreements for the European market. With the formal separation from Morgan initiated by SMS group in 2016, the previous dependency on the license was eliminated. Through gradual in‑house developments - in particular proprietary sealing and fastening solutions (HN seal, BM fastening), the X‑Roll® brand positioning, and the establishment of the own test rig - SMS today possesses its own technologies, testing methods and service offerings for oil film bearings.

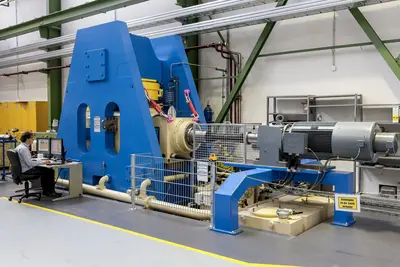

Test rig and primary development targets

The purpose-designed test rig enables realistic trials of fastening systems, seals, and prototypes under operational conditions. Since commissioning, SMS test rig has:

- Developed innovative bearing concepts

- Optimized fastening and sealing systems

- Investigated various materials and material combinations

- Delivered cost-efficient, reliable bearing solutions for customers

Prototype testing is performed at a high Technology Readiness Level (TRL) and is conducted under representative operating conditions. Original components are tested at full scale and under the typical load profiles of a rolling mill to ensure direct transferability to field operation.

Through the test-rig trials we were able to analyze the physical processes in the bearing in detail. The insights gained were directly incorporated into the development of innovative bearing technologies.

Test rig design and mechanical arrangement

The mechanical layout comprises a rigid support frame with three-point oil film bearing support: the center bearing is fixed, while the outer bearings are arranged in a fixed-or-floating configuration to reliably accommodate thermal expansion. Original oil film bearings are installed in a closed oil circuit according to OEM specifications. The circuit includes pump, filtration, heat exchanger, and measurement points for pressure, temperature and flow. The drive unit provides precise control of speed and torque to reproduce static and dynamic load profiles. The load is applied hydraulically by a hydraulic cylinder positioned above the central bearing. Calibrated load cells and oil and bearing temperature sensors are installed to ensure high measurement accuracy.

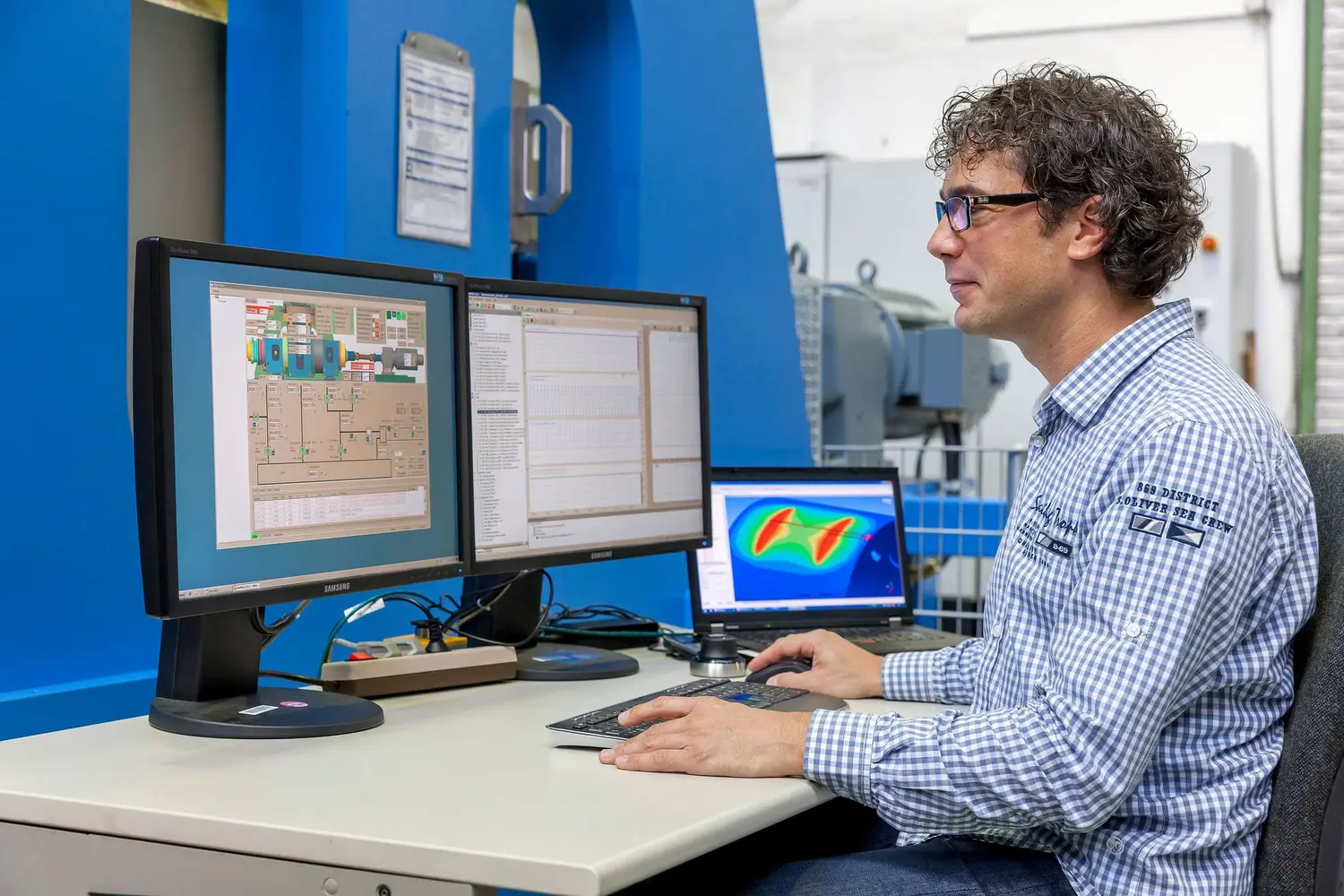

Measurement and evaluation approach specific to oil film bearings

Data acquisition is synchronized using the iba measurement system: all relevant quantities - oil film thickness, oil pressure, oil temperature, oil flow, force, speed, and, when required, vibration - are recorded on a common time base. The analysis includes determining oil film parameters and load–capacity curves, as well as evaluating thermal transients and pressure-side reactions to load changes. All results are archived in standardized files and provided in automatically generated test reports with graphical outputs.

Fully automated test procedures

The test execution begins with system initialization and verification of safety and process parameters, followed by automatic locking of the roll assembly. During the pre‑heat phase the oil is brought to the target temperature and the oil circuit is stabilized. Thereafter test speeds are ramped up, and static or dynamic loads are applied while oil pressure and supply-line temperature are regulated. Throughout the entire test, pressures and bearing temperatures, oil flow rates and forces are measured, monitored and recorded continuously. If limits are exceeded or emergency conditions occur, the system automatically executes load-abort and safety sequences. Data export and report generation are then triggered automatically.

Safety and standards compliance

The test rig design complies with the Machinery Directive 2006/42/EC and incorporates required interlocks, redundant emergency‑stop circuits and access protection. Over‑temperature and over‑pressure protection are integrated into the control logic. Workplace and operational safety measures follow relevant DGUV and ISO standards to ensure safe operation during assembly, testing and maintenance.

Oil film bearings form the core of every rolling mill. They provide the critical connection between the rotating rolls and the fixed, stabilizing, and regulating components of the mill. Through continuous testing and the development of new technologies, we create real added value for our customers—in the form of highest operational reliability, optimized performance, and extended component life. As a reliable partner, we offer comprehensive services for your bearing technology.

Performance data, instrumentation and data analysis

The test rig is designed to enable testing under demanding operational conditions and realistic extreme load scenarios corresponding to field operation. Its key performance parameters include:

- Maximum rotational speed: 300 rpm

- Maximum force: 20 MN, of which 11 MN is applicable to the test bearing

- Hydrostatic pumps: pressures up to 2,000 bar for simulation of slowly rotating supports or standstill conditions

The rig is equipped with modern, high‑resolution instrumentation to produce meaningful results:

- Measurements on oil circuit: pressure, volumetric flow and temperature at all supply and return lines of the test rig, in particular at the test bearing

- Integrated oil‑film sensors (partial): pressure, temperature, deformation and clearance/oil‑film thickness

- Evaluation: automated electronic data acquisition and modern signal processing

- Test control: automated execution of long‑term programs with varying load profiles

The combination of high‑resolution sensing and automated analysis permits robust statements on service life, leak tightness behavior and lubricant‑film stability and forms the basis for optimization of new bearing designs.

Customers benefit from optimized, cost-effective bearing solutions and minimized implementation risk through iterative prototyping, ensuring reliability and performance that seamlessly transfer to field operation.