Starting with the 1st PQF® in 2003, several developments to the design have been achieved. In 2021, SMS group has put a lot of effort in developing the Fast Inlet Side, a new feature for PQF® – Premium Quality Finishing plants. This new high-speed inlet side enables an increase in productivity, but also an improvement of energy efficiency, tool consumption and safety standard.

An implementation of the new Fast Inlet Side is not only possible in new PQF® plants; but also existing PQF® plants or 2-roll mandrel mills can fully benefit from this low-investment upgrade.

Enhanced efficiency: Introducing the new fast inlet side process of the PQF®

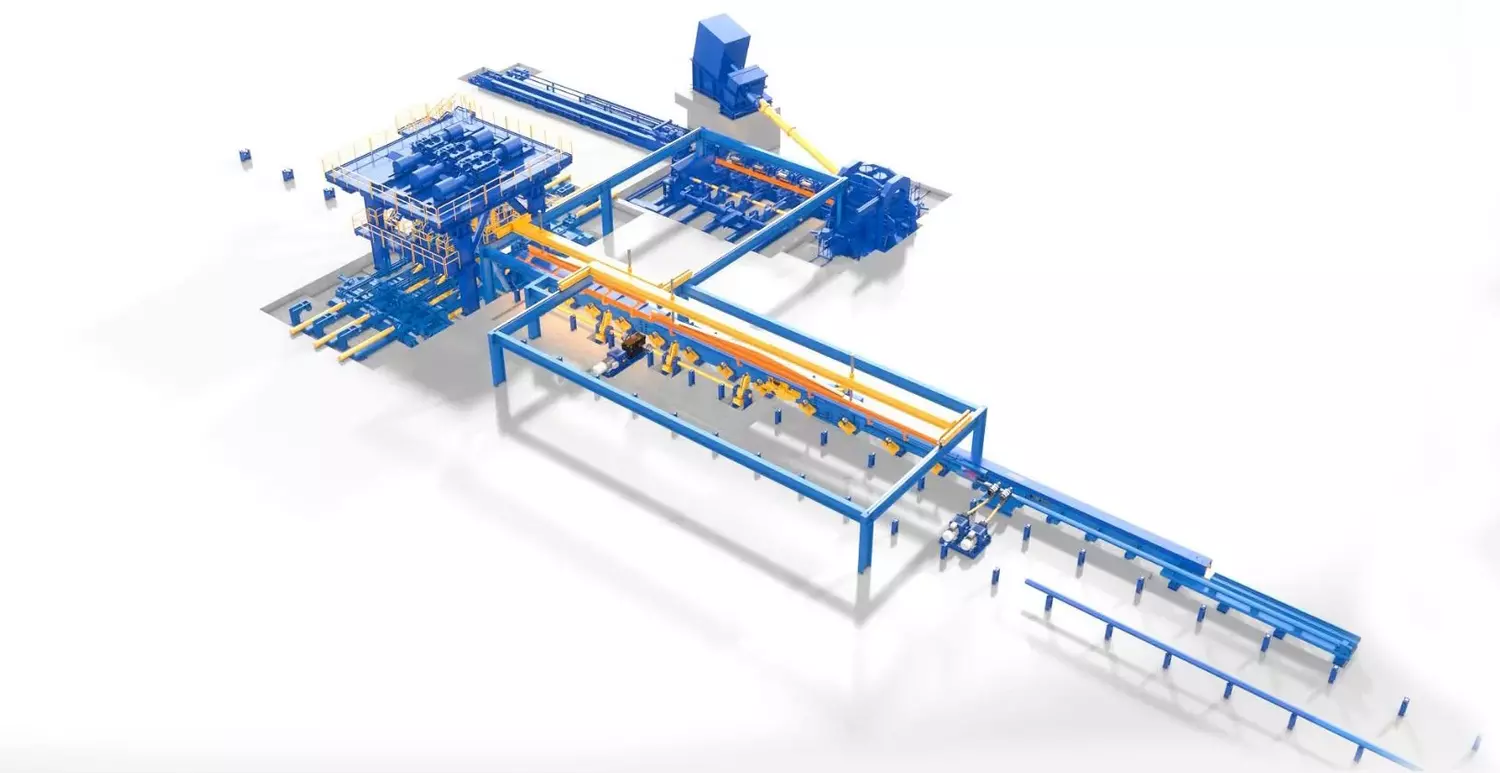

The new functionality and process of the Fast Inlet Side of the PQF® can briefly be described as follows: The hollow bloom coming from the piercing mill is picked up by a manipulator from the deoxidation position and is lowered directly onto the rolling line in front of the PQF®. A so-called rack-type pre-inserter inserts the mandrel bar into the hollow bloom laying in front of the PQF®. Prior to insertion, the mandrel bar is already positioned optimally considering the minimum distance required by the process.

The main retainer head is accelerating and at the right time takes over the rolling process and the pre-inserter moves back to its starting position for the next cycle.

After rolling, the main rack also reverts to its starting position allowing the mandrel bar to transfer out of the rolling line and onto the cooling line at the earliest possibility. The next mandrel bar is positioned in the Fast Inlet Side and the next rolling cycle can start.

Increasing productivity and sustainability in mandrel mill operations

Overall, the new design solution reduces the cycle time by up to 30% compared to actual 3-roll retained mandrel mills in operation worldwide. Aside from the faster cycle, allowing for higher productivity, the reduced time also brings advantages to other process parameter. With the faster cycle, the heat loss of the hollow bloom is reduced and reheating parameter can be optimized. This reduces fossil fuel consumption and directly impacts efficiency and the mill’s carbon footprint. But not only fuel consumption can be reduced, also electrical energy consumption is affected. The dynamic loads of new Fast Inlet Side are lower than with a conventional solution, subsequently requiring less power.

The Fast Inlet Side further extends the service life of the mandrel bars. Through the faster rolling cycle, the contact time of the bar with the hollow bloom is shortened, reducing the thermal loads on the tooling.

At last, also from a safety perspective, the Fast Inlet Side brings benefits to producers. The position of the retainer head in relation to the mandrel bar has been modified. Conventional solutions have them aligned in the rolling line. The new design of the Fast Inlet Side puts the retainer head off the main rolling line featuring the benefit in case of a sticker. In case of a sticker, the retainer head is not affected by the sudden impact and damages to this critical component can be avoided.

Our new development for PQF® plants represents a really unique and highly attractive offer for tube manufacturers.

SMS group's advanced technologies elevate quality and precision levels of PQF® tubes

The consistently high quality and precision levels of PQF® tubes are ensured by the rolling technologies and the performance module from SMS group. These include the advanced, digital inline technologies as part of Industry 4.0: For example, the CaliView® measuring system, developed by SMS group, enables the fast inline calibration of all longitudinal rolling mills and thus guarantees perfect alignment of the pass line. Furthermore, CARTA® neo supports process engineers with the monitoring, analysis, and intelligent control of all quality parameters.

The new Fast Inlet Side adds to these solutions. With ensuring a fast handling of the hollow bloom the temperature loss between the two rolling processes piercing and elongation is reduced thus supporting a high quality result on the final product.

We are convinced that our new feature for PQF® plants represents a really unique and highly attractive offer for tube manufacturers all over the world. Our team is on hand to present the technological innovations and the economic benefits to plant owners and interested parties.