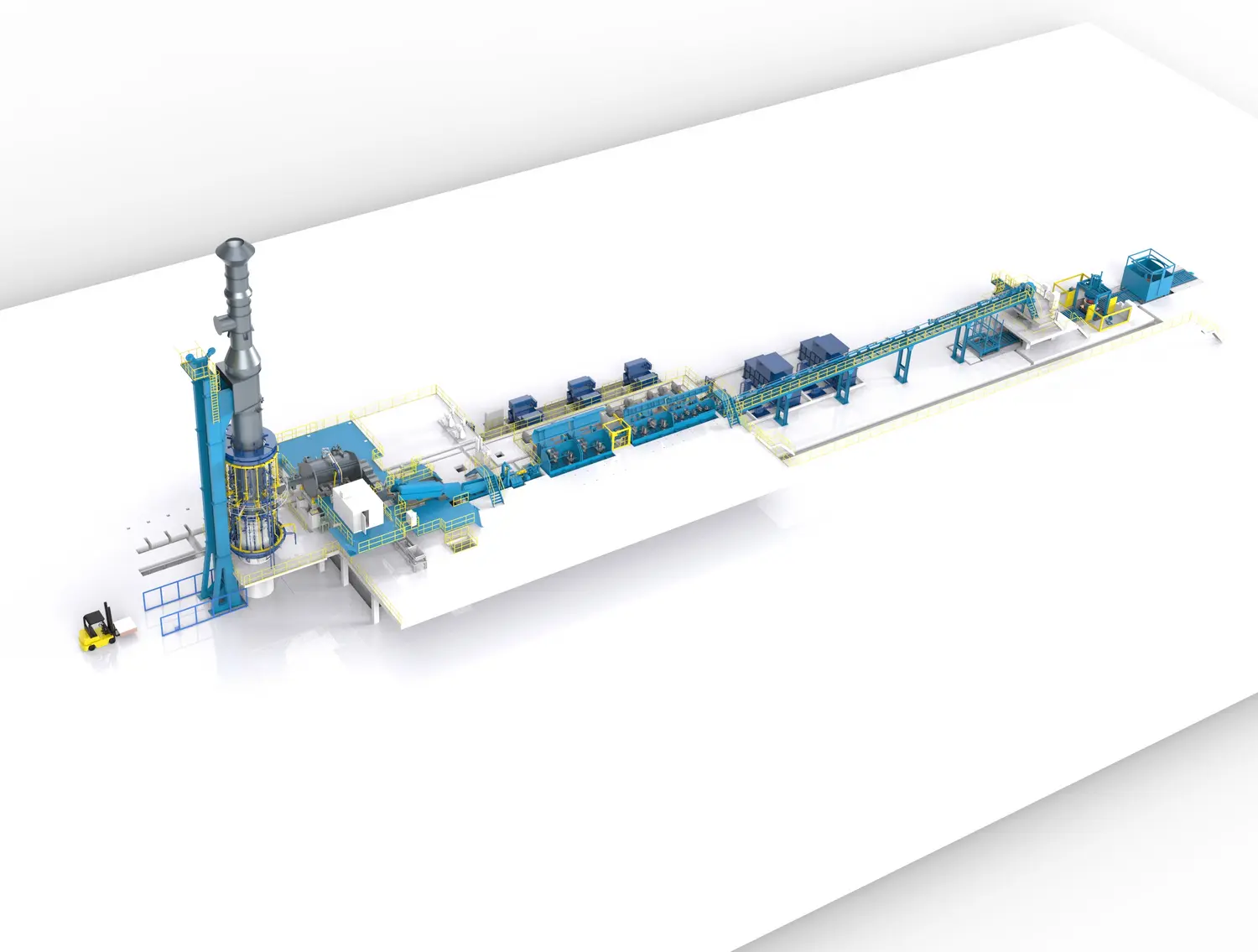

Optimize your copper wire rod line with our comprehensive lifecycle solutions

To enhance the efficiency and longevity of your copper rod lines, we offer a complete range of service solutions, including maintenance services, spare parts, repairs, and modernization solutions to boost your copper rod lines' efficiency; our tailored approach ensures that every need is met with precision. Additionally, we provide digital solutions such as SMS-Metrics, the comprehensive solution combining advanced analytics with continuous development and expert consulting services.

By partnering with us, you are choosing to elevate your operations to new heights. Our solutions are crafted to fit seamlessly into your workflow, ensuring optimal performance and reliability. Experience the difference of a true lifecycle partnership, where innovation meets excellence.

Customer challenges addressed

- Maximizing uptime: Our equipment is designed for reliability and continuity, ensuring minimal interruptions. Solutions like spare eccentric bushings and real-time monitoring systems enhance recovery speed and support seamless production flow.

- Optimizing operational efficiency: With innovative technologies such as the transfer launder unit and SMS hybrid nozzle, we enable energy-efficient processes and streamlined operations, boosting overall productivity.

- Achieving excellence in product quality and sustainability: Our solutions support the production of superior copper rods while aligning with environmental standards, ensuring both quality and sustainability.