How has your company developed in recent years and which products do you chiefly manufacture?

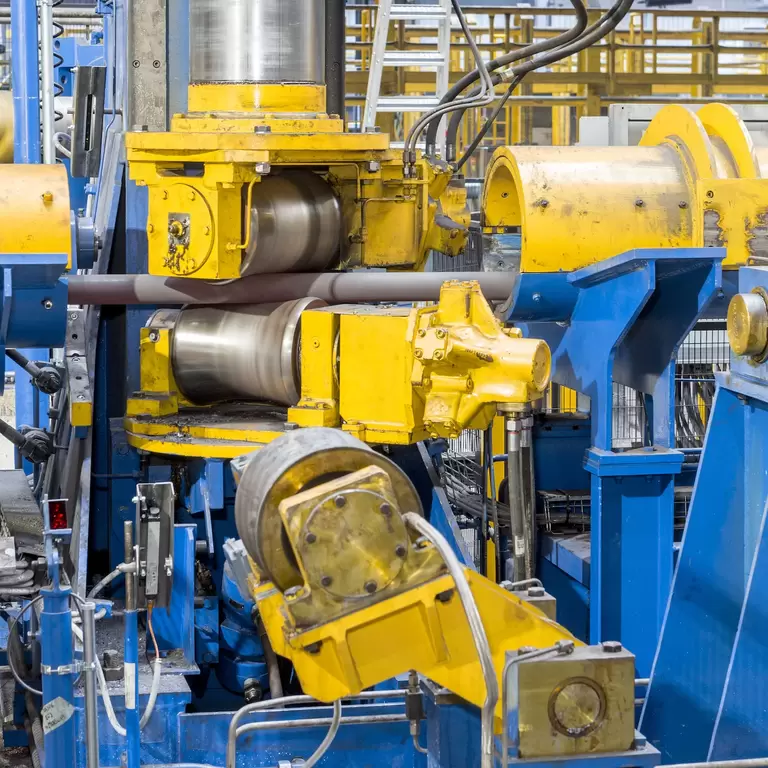

Reinhold Reisner: voestalpine Tubulars produces seamless steel pipes for the oil and gas industry as well as other industries – such as automotive, mechanical engineering, construction and petrochemical. There have been a number of R&D projects together with our customers for tailor-made solutions, which resulted in new materials and thread connections to better meet our customers’ needs.

So what made you decide right now, during the current times, to invest into your new equipment?

Reinhold Reisner: Oil and gas exploration and production have become increasingly challenging and critical, changing the requirements of our customers. These requirements drove the need for pipes with unique properties and new steel grades, which require state-of-the-art heat treatment processes. The heat treatment expansion enables us to meet these requirements.

Thanks to the investment you are now in a position. What made SMS group the right partner for your investment?

Helmut Jungbauer: More than 35 years ago SMS built a large part of our hot rolling mill, with many other parts having been added over the years, such as two straighteners and now SMS was invited to provide us an offer also for the heat treatment mill expansion. For us it is very important that we have a long-lasting relation-ship with SMS and we have seen that they deliver us with proven quality and machinery. Furthermore has the cooperation with SMS group been always very structured and based on long-term experience on both sides. And it is very important for us, that SMS group has always met the agreed delivery dates.