Versatile, organically coated steel strip

Organically coated plate is increasingly being used wherever aesthetics are required in addition to corrosion resistance. Aside from the construction industry, coated plates are demanded by household and electrical appliance manufacturers as well as by the automotive industry. Compared to coating individual pieces, the continuous coating of steel strips – coil coating – reduces production costs.

From a technical perspective, the highlight is the compact coating process, but we also ensure the chemical strip pre-treatment, subsequent color coating, and drying oven are perfectly synchronized. That way, you achieve excellent quality at low resource and energy consumption.

-

Color coating line

For automotive and household industry, architecture and electrical appliances

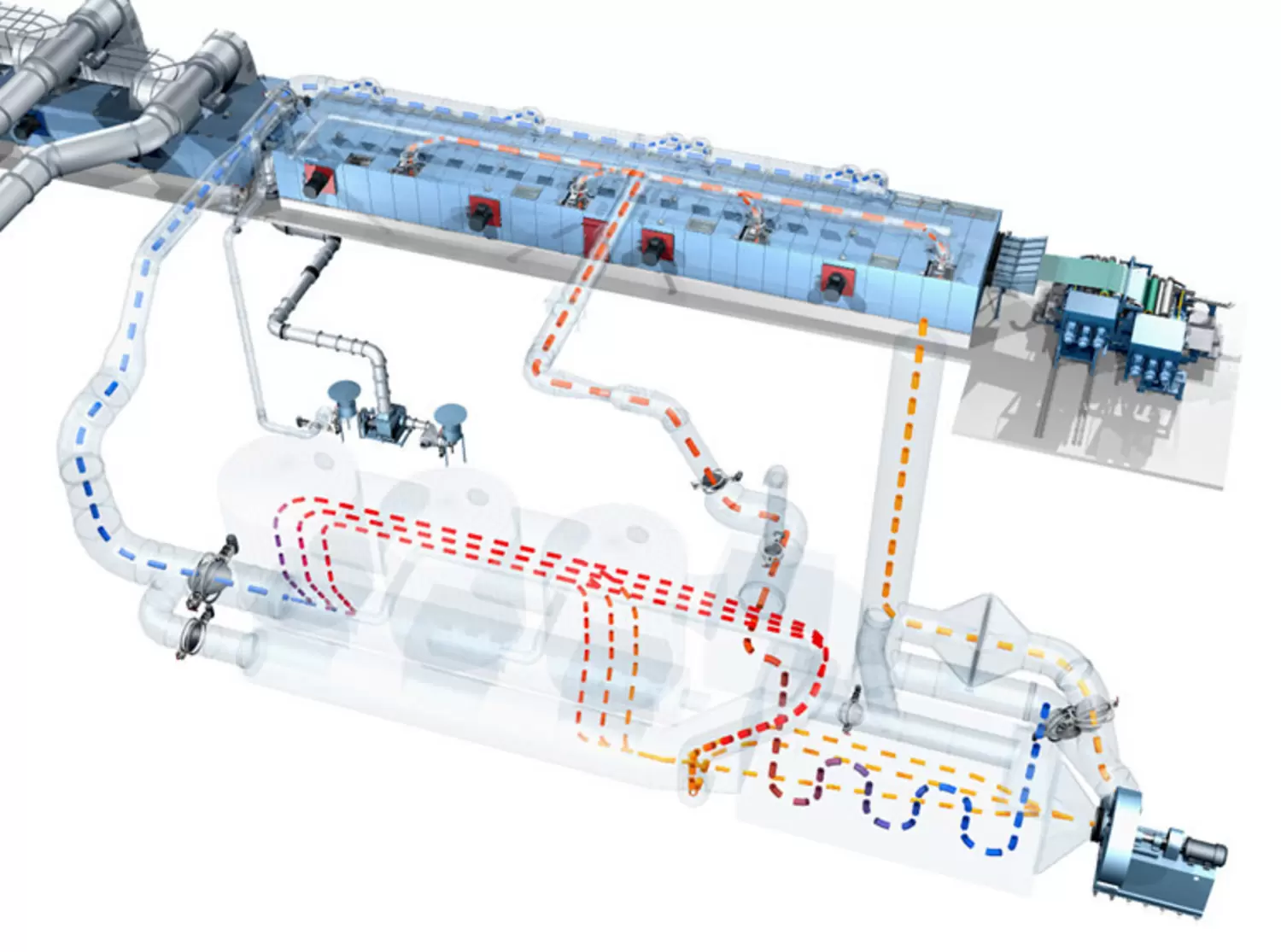

In a color coating line, the strips enter the line alternately from two payoff reels and are joined by a stitcher into endless strip. The endless strip collects in a vertical looper. Next up is a spray and brush degreasing unit that cleans the strip surface.

Then a chemcoater applies a conversion layer, followed by vertical drying. The strip is primed in a prime coater, then goes through the first horizontal hardening furnace. As it travels through the two finish coaters, it is coated with a top coat that hardens in the second horizontal furnace. The next station is a vertical looper. Downstream of this is an inspection stand that checks the strip before it is cut and wound into coils.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Coating technology

Precise and reliable coating

We offer a comprehensive range of coating systems for color coating lines. Whichever type you choose, you benefit from top precision and reliability. Just as dependable is our closed-loop thickness regulation system because it guarantees precise coat thickness every time.

![]()

In the vertical coater, the strip is prepared for the next coat with a conversion coating. -

Drying technology

Contactless and efficient drying

Our high-performance catenaries or ovens for drying the solvents stand out for even heating and cooling as well as exceptionally high efficiency. Furthermore, they come with top green credentials. Also available to you is our special floatation furnace for thin gauges.

Modular and compact in design, our high-performance convection furnaces stand out for even heating and cooling performance, exceptionally high efficiency, and eco-friendliness. All this requires ideal setting and control of the process parameters. We apply a mathematical model to get this right every time.

The process starts with the catenary oven, where the strip is uniformly heated over the entire length. Here, the upper and lower air streams are each generated by their own frequency-controlled turbine. That makes it possible to separately control the energy used in each individual oven zone. Furthermore, the whole air flow is aerodynamically designed to obtain an efficiency of 50 percent based on a uniform flow pattern. This means a huge volume of air circulates in the oven at a temperature of between 300 °C and 400 °C and heats the strip to the required temperature of up to 270 °C. Generally, the ovens draw their energy from the efficient energy recovery system. That consists of a regenerative post-combustion system plus additional burners

![]()

-

Regenerative thermal oxidizer

Coating technologies designed to your requirements

Our regenerative thermal oxidizer system burns the flue gases in the oven with a thermal efficiency of 98%. Depending on the solvent content in the exhaust air, the afterburning system and even the oven itself can be operated without additional energy input (autothermal mode).

![]()

Regenerative thermal oxidizer -

Process control

X-Pact® automation for color coating lines

What do our control solutions mean for you? Quite simply, excellent technology and functionality that ensure you achieve your target values by means of hydraulic and electrical control elements.

-

X-Pact® Strip Process Optimizer

A key to increasing the efficiency of modern processing lines

X-Pact® Strip Process Optimizer is a key to increase the efficiency of modern processing lines. It is integrated into all activities regarding engineering, commissioning or research and development of strip processing lines. In addition to its role as a data hub, improving product quality and increasing production volume and flexibility are the main tasks of our Level 2 solution, which is partly based on mathematical and physical process models. X-Pact® Strip Process Optimizer guarantees maximum reliability, increases process stability, reduces downtimes and enables a high degree of independence in production.

![]()

Services for this plant

Sorry, there are no results for the search term.