Hydrogen will shape the future of the metals industry

Green hydrogen will play a pivotal role on the path towards a climate friendly metals industry. It will not only be a key tool in the path towards CO2 reductions in iron and steel making processes, but renewable hydrogen will also be required for other non-electrifiable sectors, such as aviation. SMS group is taking an active role in shaping the supply and use of hydrogen, as well as developing and offering hydrogen-based solutions for industrial applications. A hydrogen competence center has therefore been created at the SMS group subsidiary Paul Wurth in Luxembourg.

Green hydrogen generation

Here's a constellation that rarely happens: An industry whose demand for hydrogen is rising steadily meets a hydrogen specialist looking for industry partners. That is why SMS group became a strategic investor and technology partner in Sunfire GmbH in 2019.

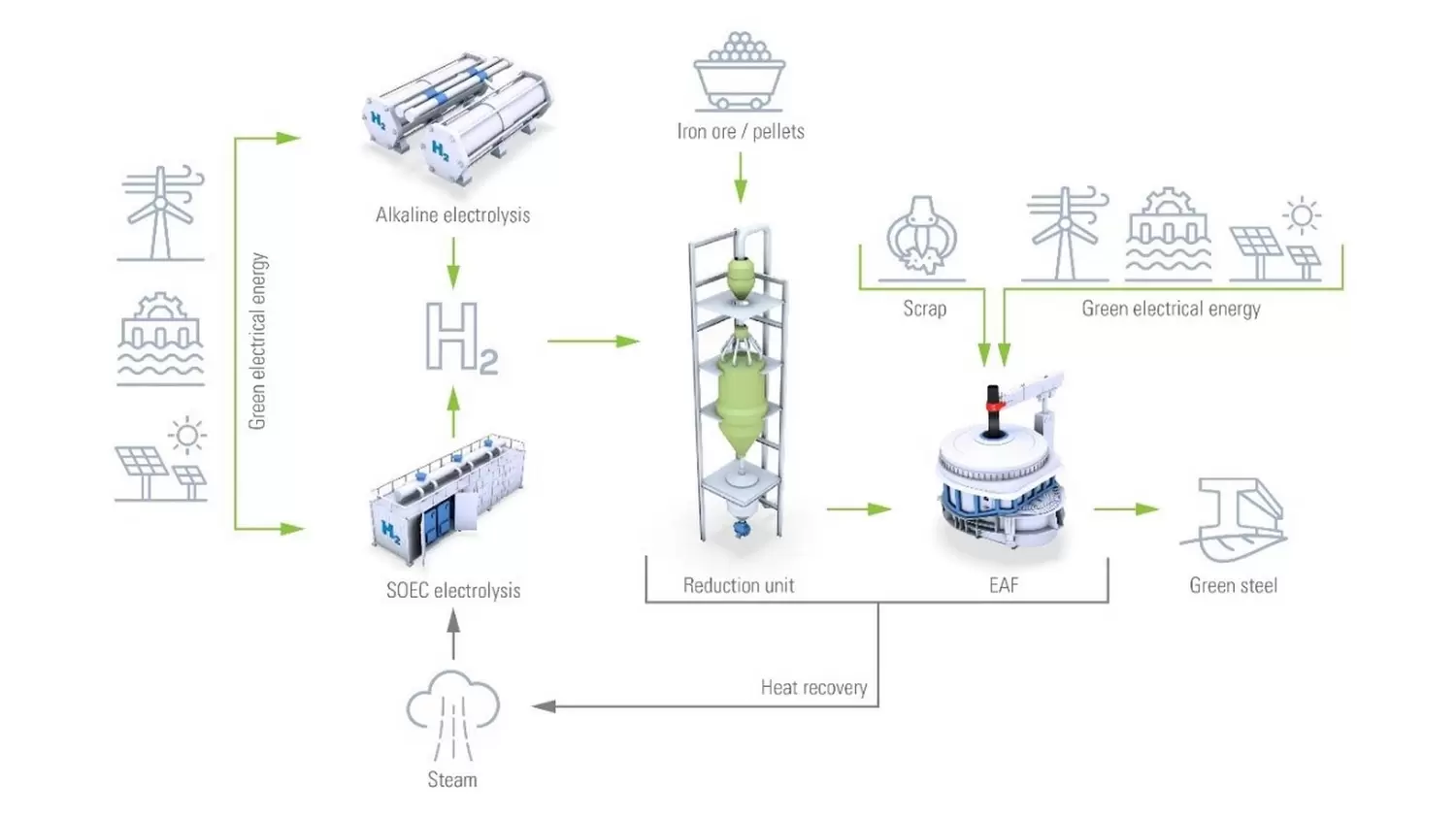

Sunfire has developed an efficient process for high-temperature electrolysis. The difference from traditional electrolysis is that steam is used instead of liquid water, because it is split more efficiently into hydrogen and oxygen. As the steam can be generated from waste heat from industrial plants, this process is ideal for all steel mills. Compared with conventional electrolysis, the process can save 20 to 30 percent power and do so with significantly higher efficiency. Besides, Sunfire also offers the Alkaline electrolyzer technology which is proven and matured in many industrial references. The Alkaline electrolysis is especially dedicated to locations, where for instance waste heat is not easily available.

The strategic partnership is a foundation to integrate hydrogen production with the steel industry. It is a perfect example of the type of forward-looking approach that opens up integrated, state-of-the-art solutions for our customers. Our metallurgical expertise lays the foundation for sustainable progress in the complex world of metals, whilst opening up new opportunities for emission reduction.

The role of SMS group and Paul Wurth in this partnership is to support Sunfire in capacity building and technology development, and to cooperate in the implementation of complete turnkey projects. With over 150 years of experience, SMS group functions as an access provider to the global metals industry, which increasingly uses renewable hydrogen.

Hydrogen for #turningmetalsgreen

The steel industry faces major challenges to comply with climate policies and emission reduction targets. Today, the steel industry contributes around seven percent to global CO2 emissions. Therefore, SMS group is constantly developing and is already providing low-emission and carbon-neutral technologies for green metals production. Renewable hydrogen thereby plays an important role in the different routes that SMS group is offering.

When available at a fair cost and on a large scale, green hydrogen plays a pivotal role in cutting emissions in the steel industry as it is a perfect reducing agent for substituting the fossil fuel-based iron ore reduction.

Hydrogen shows its full potential in this ‘metallurgical’ application as it has a significant leverage effect: using one metric ton of green hydrogen in steel production saves around 26 metric tons of CO2, compared with the classic blast furnace route.

SMS group email service

Our promise to you: this is not another newsletter!

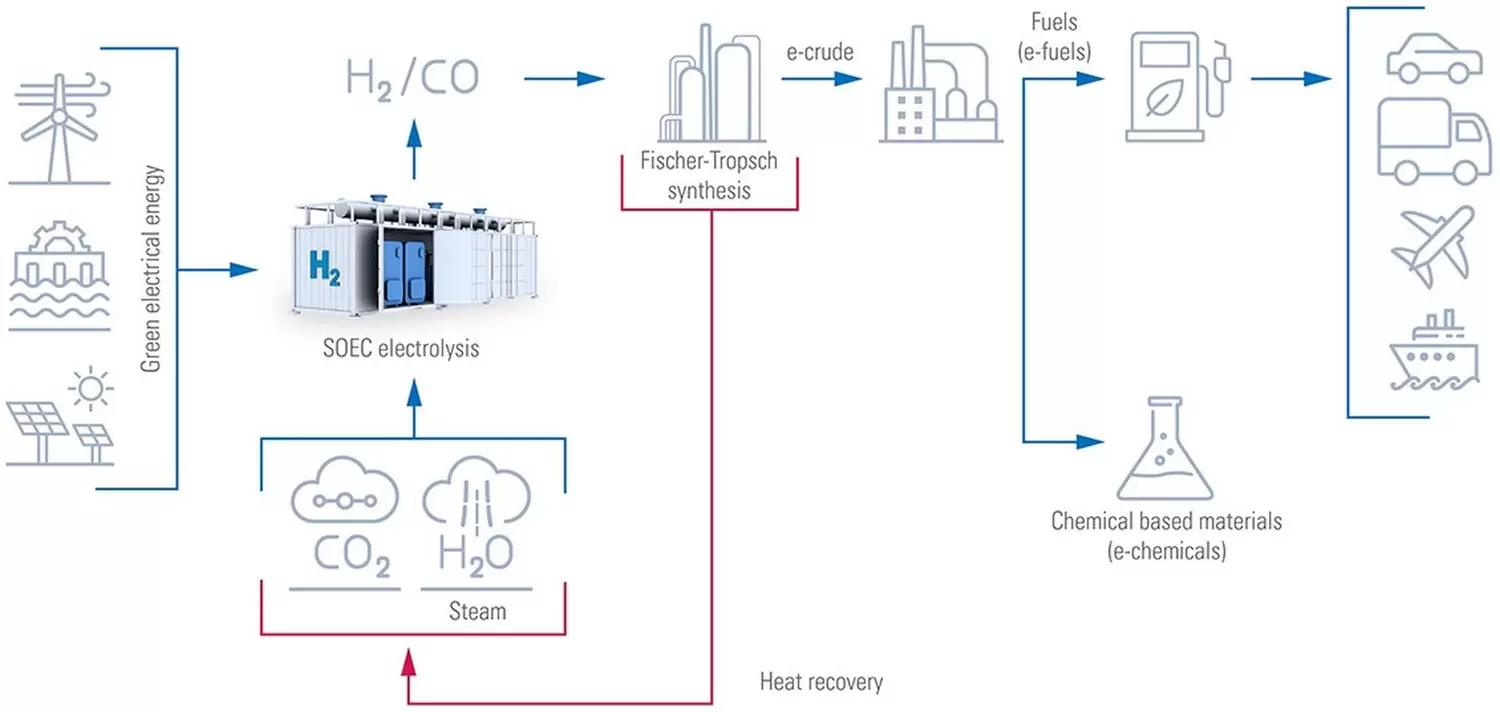

Power to X – Production of synthetic fuels

SMS group is also involved in the development of projects for the production of synthetic fuels. Replacing fossil fuels with synthetic fuels produced by CO2 and water is particularly interesting for hard-to-electrify sectors such as the aviation industry and other heavy goods transport by road and sea. Compared to electricity from renewable sources, synthetic fuels are easier to store and to transport and are therefore considered today as a necessity for advancing the energy transition.

In 2020, SMS group subsidiary Paul Wurth and partners founded the Norwegian company Norsk e-Fuel – a consortium focussing on the production of sustainable aviation fuels in particular. Norway, with its under-utilized hydropower capacities, offers good economic conditions for producing such fuels from CO2 and hydrogen due to the availability of low-cost green electricity. The Norsk e-Fuel consortium is planning the first e-fuel plant in Mosjoen, Norway, with production starting by end 2024.