Challenges of manual measuring methods of products in cold condition

The conventional approach of checking for adjustments only after the product has cooled down leads to several issues. Since deviations become obvious by the final production stage, this method presents disadvantages for plant operators, such as the loss of the entire production batch if a deviation is detected, increased downtimes due to periodically occurring faults and production tolerances that cannot be fully exploited. The lack of individual product inspection means that not every product is checked, allowing potential defects to slip through.

Immediate detection of dimension and surface anomalies is key

To address these challenges, plant operators need to be informed of dimensional and surface deviations as soon as they occur, typically immediately after the last stand. SMS group offers autonomous laser measurement systems designed to check dimensions and surface deviations for long products, optimizing the production process and exploiting production tolerances. The TBK laser systems enable early detection for immediate identification of surface and dimensional anomalies in hot and cold product conditions. Measurement of hot products allows for production adjustment within the first operation stages so that the rest of the batch can be produced according to the requested standards. Conformity verification ensures that every product meets specified standards. The system enables 100% batch inspection. The prevention of periodic errors is possible by detecting and addressing recurring faults promptly. High accuracy in measurements ensures precision to fully exploit production tolerances.

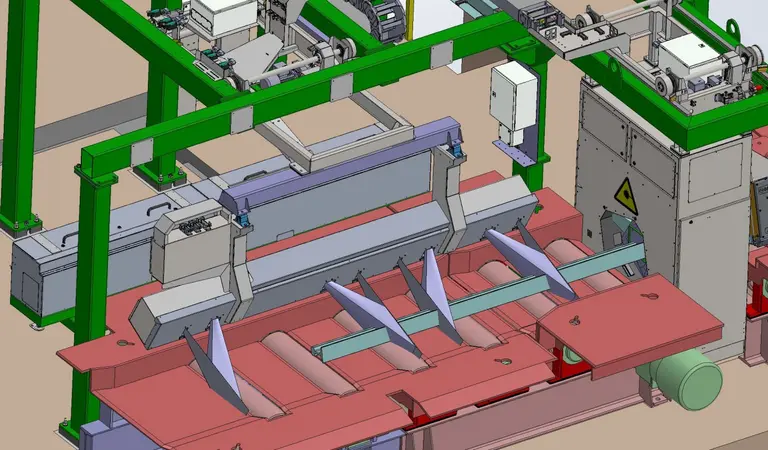

TBK laser measurement solutions simplify product measurement with laser light-section technology

The TBK autonomous laser measurement systems from SMS group efficiently and accurately measures profiles and surfaces of rolled long products by using laser light section technology showing the real contour not only an extrapolation of this contour. Laser light-section technology is used for hot- and cold- rolled long products, providing complete profile measurement and surface detection. Geometric analysis is conducted using four or eight sensors for detailed geometric analysis. Unlike conventional shadow methods that create maximum 12 measuring points per cross-section to estimate a contour the laser light-section technology creates more than 300 single measurement points per each single cross section of a bar. This method uses the scattering of laser light, making it more efficient and accurate.

Dimensional product measurement with TBK gauges

TBK laser measurement systems are tailored for dimension control and surface analysis of rolled products, including wire rod, bars, rebars, sections, rails, tubes and special products. Product dimensions are measured with gauges matching individual product requirements. The gauges are available for all shapes due to the laser triangulation method for profile measurement. Sensors provide non-contact measurement by capturing up to 1,000 contours per second for rounds and 500 contours per second for other profiles, ensuring complete contour capture of the product. Based on the triangulation principle, the sensors project a plane of light onto an object. The plane of light forms a line on the product surface. The line is diffusely reflected and imaged on a CMOS sensor. Each column of the image array yields one coordinate point. Together, all the points describe the contour of the product. Plant operators can track dimension deviations by the 2D and 3D models displayed on the human machine interface (HMI), providing detailed information about deviations and their causes.

Product surface anomalies detection with TBK SurfTec

The TBK SurfTec system enhances surface analysis by increasing the cross-section rate to up to 15,000 cross-sections per second, enabling the detection of very small defects. SurfTec can be added as an add-on to the dimensional measurement gauges without additional construction work in the line. The surface of each single product passing the gauge is checked. Also this system generates 2D and 3D models displaying surface anomalies on the human machine interface (HMI), providing detailed information about deviations and their causes. The strength of the deviation in height or depth is displayed in color. Thus, it can be quickly determined whether a roll is damaged, scratches caused by guidings occur, or defective starting material was supplied.

Boosting quality and efficiency with precision measurement

SMS group’s TBK measurement solutions meet key performance indicators for increasing product quality and process efficiency. Dimensional measuring repeatability comprises a spectrum from down to +/- 0.004 mm (1σ) for wire rod and +/- 0.007 mm (1σ) for large sections. Dimensional measuring accuracy covers a range of down to +/- 0.015 mm (2σ) for wire and down to +/- 0.25 mm (2σ) for large sections. The system ensures that 100% of the production batch is analyzed, providing complete inspection and quality assurance.

By reducing delay times, minimizing material loss and fully exploiting production tolerances the production process becomes more efficient.

SMS group offers the full package with its TBK laser equipment

By combining the expertise of two engineering companies, a full package can be provided to customers. This joint expertise ensures a comprehensive view of the entire rolling mill, facilitating the installation of the laser measuring equipment in the respective rolling mill. Customers benefit from a direct connection to all of SMS's competencies, including mechanics, electrics and automation, digital solution and maintenance service:

Single source of supply & truth: Customers receive a joint solution, simplifying procurement and implementation processes.

Holistic plant perspective and consulting: The combined knowledge allows for a holistic understanding and optimization of the plant's operations.

Easy upgrade: Existing TBK gauges can be easily upgraded with SurfTec installation without any additional constructional works at any time, ensuring flexibility

Spare parts guarantee: A minimum of 10 years of spare parts availability ensures long-term support and reliability.

More information on TBK laser measurement systems

Learn more about our customized measurement solutions for long products.