Producing seamless shells for demanding industries requires absolute consistency in material condition, geometry and traceability. The process requires uniform heating and high forging accuracy to produce thick‑walled components with tight tolerances and a defined interior profile.

Fully automatic forging line for consistency in material condition, geometry and traceability

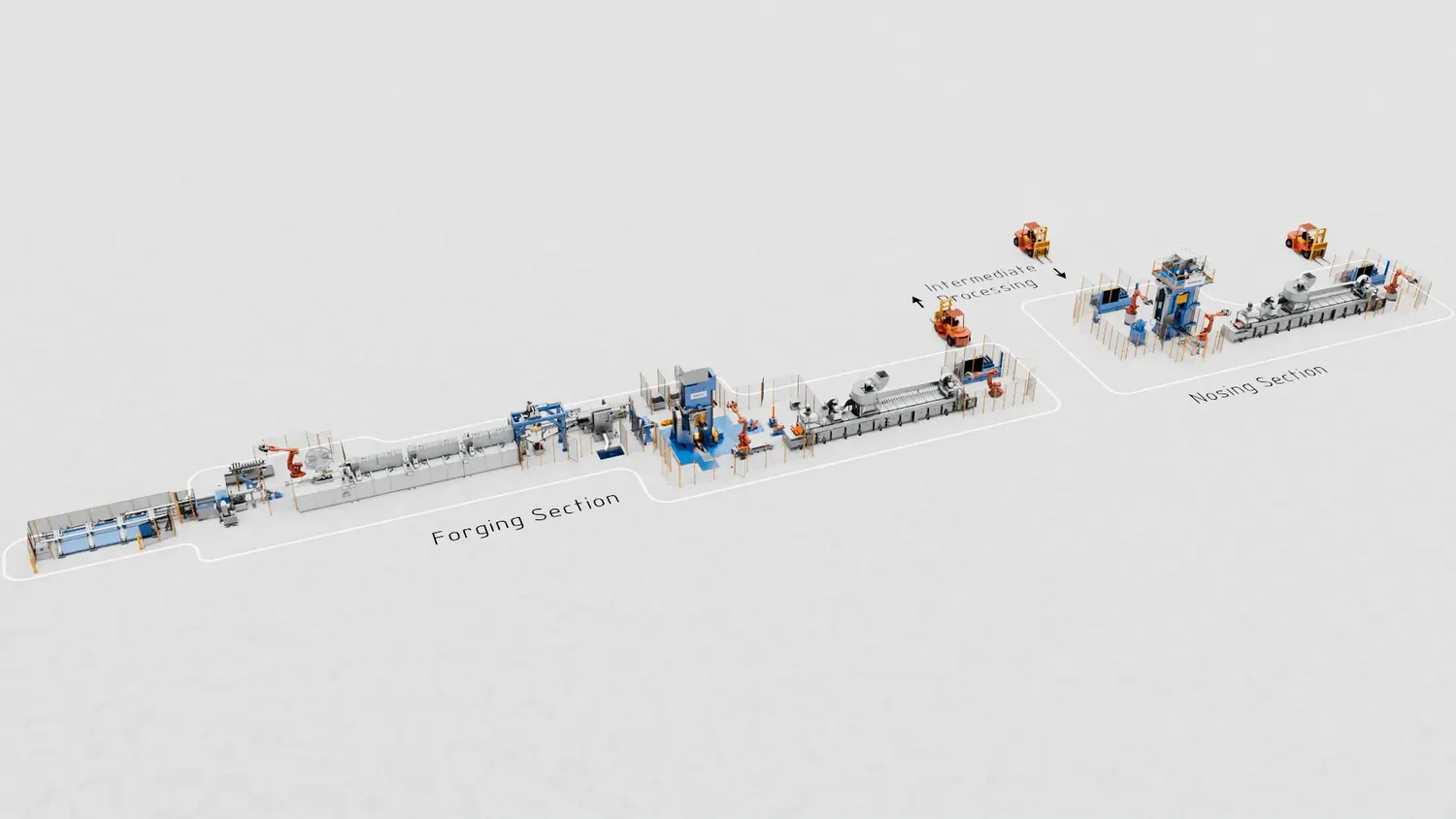

Our fully automatic forging line for shells and hollow components is engineered to convert the product requirements into reliable production performance coupled with high productivity. Designed and manufactured entirely in-house, the integrated line includes induction furnaces, hydraulic piercing and drawing press, nosing press, and advanced automation. Inline sensors and nondestructive testing detect deviations early and feed corrective actions directly into the process to ensure consistent product quality and process stability. Process-integrated part marking provides complete batch traceability throughout production.

The line control system enables optimized operation of the entire plant by centrally visualizing and monitoring all critical data from machines and robots in real time. By coordinating and controlling processes across the entire line, the system delivers maximum performance and throughput under all operating conditions without requiring manual operator intervention. In addition the SMS group technical service provides training for operators and maintenance personnel, enabling optimal operating performance from the start.

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

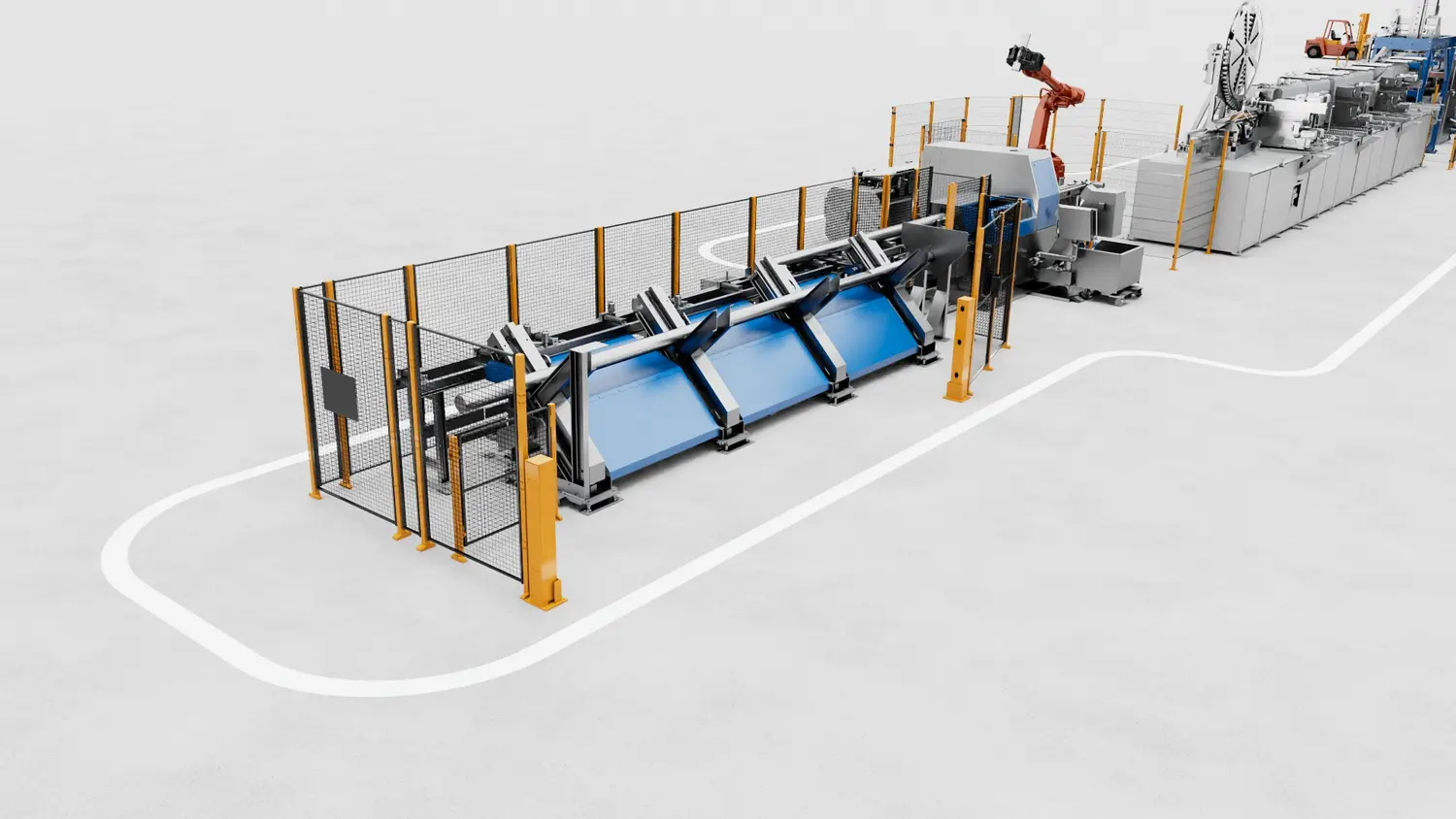

Preparation that matters

After automated billet loading, an integrated sawing unit with an on‑board scale ensures dimensional control for every cut. Induction furnaces provide uniform heating and repeatable thermal conditions, while descaling equipment reliably removes surface scale prior to forging. Together, these features enhance process reliability and create optimal conditions for the subsequent forging step, consistently producing parts that meet the required dimensions and metallurgical properties.

-

Advanced hydraulic piercing & drawing press technology

The core machine of the line - the hydraulic piercing and drawing press - delivers tight forging tolerances through precise control of forging parameters and a robust machine design. Its outstanding feature is multifunctionality: upsetting and piercing occur in a single lower die, directly followed by a drawing operation, to produce the long, hollow, closed‑bottom workpiece that serves as the input for the nosing process . The press maintains repeatable force, speed and stroke, while a rigid frame, accurate guides and robust bearings minimize deflection and wear.

-

Final forming on the hydraulic nosing press

The hydraulic nosing press performs the final step, shaping the ogive on the hollow forging. Each workpiece is partially heated and automatically fed into the press for precise, repeatable nosing. The press features a high‑stiffness frame, a simple and robust design, and long operational durability, ensuring reliable production with minimal maintenance requirements.

Services for your plant

Sorry, there are no results for the search term.