Tested and optimized designs with higher performance

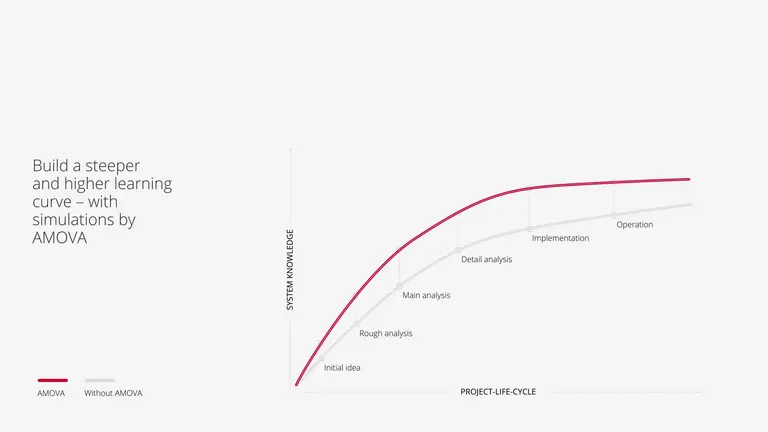

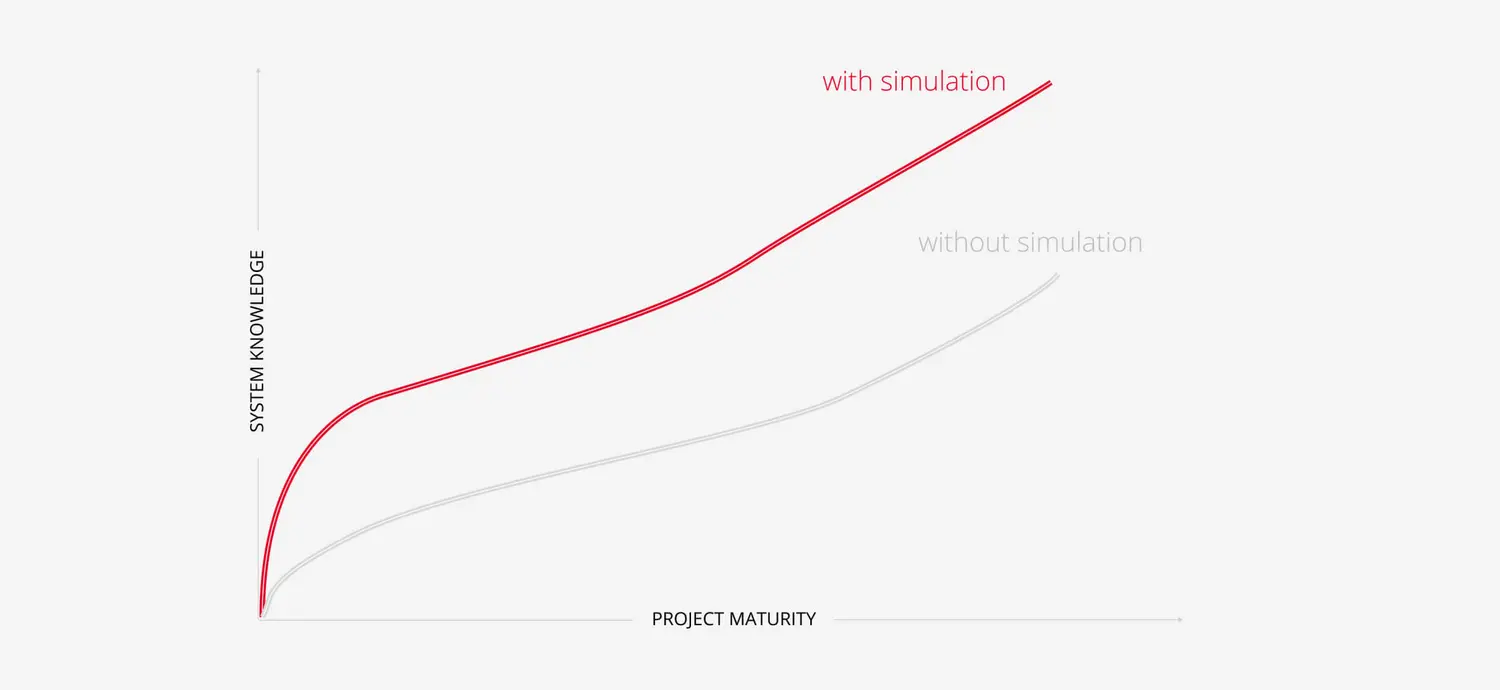

We develop discrete-event simulation models of facility concepts as well as plant and terminal designs, aiding system configuration and enhancing project transparency. For example, the simulation modelling technique allows for thorough analysis of comprehensive material flow scenarios and dynamic system interactions.

Four reasons for simulation studies

- System verification: Contrary to standard throughput estimation methodology, using static calculations, discrete-event simulation captures complex and dynamic system interactions that otherwise would have been neglected by static calculations.

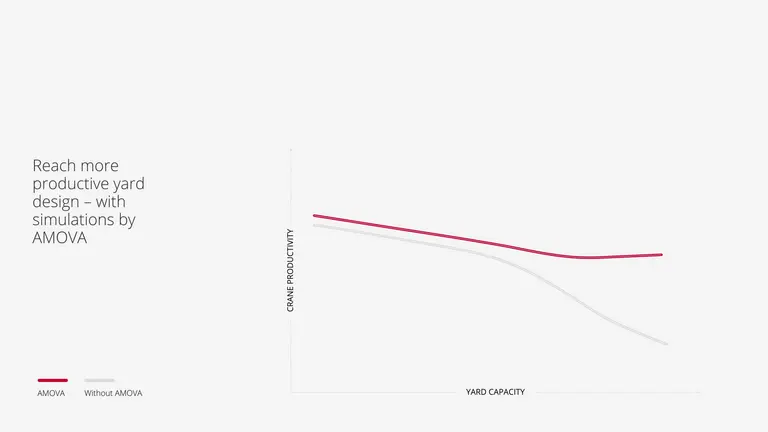

- Design optimization: A simulation model comprises the layout as well as relevant equipment. Adjustments can be made to e.g. equipment configuration, design or layout and the impact on relevant performance indicators can be evaluate

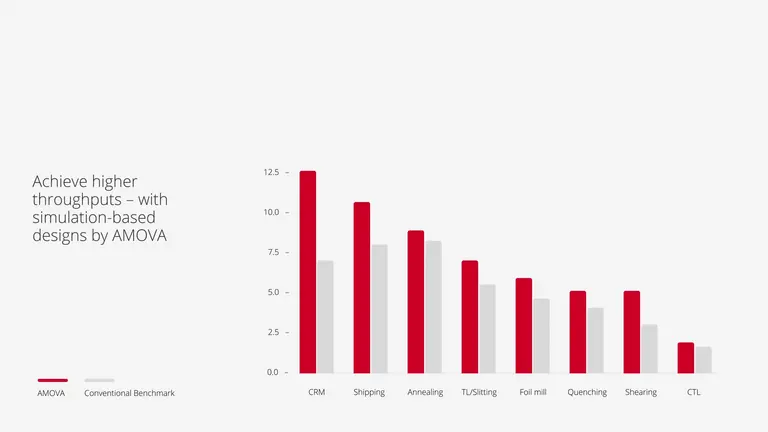

- Throughput maximization: Besides optimal design configurations, simulation studies also focus on relevant system logic, such as e.g. warehouse management algorithms. In a simulation, these algorithms can be optimized to maximize throughput.

- Increased transparency: The simulation development process repeats crucial steps of the design process, thereby re-assessing them. The model itself allows for deeper insights into interactions between abstract logics that the human mind could otherwise not comprehend.

Types of simulation studies

-

Feasibility studies

-

Feasibility studies aim at proofing the functionality of a system. Their focus is on providing decision support related to the rough-cut design, concept and layout.

-

Throughput verification studies

-

Throughput verification studies can, for example, verify the maximum possible throughput rates at various entry and exit points in a high-bay storage system, subject to defined material flow ratios and specified warehouse management logics.

-

Simulation studies

-

Simulation studies dealing with the optimization of warehouse management algorithms have their primary focus on implementing and testing different warehouse management algorithms to see which algorithms performs the best. An example for this could be the scheduling of storage good to high-bay storage aisles and high-bay storage locations. A simulation model provides a canvas for different versions of algorithms, allowing for investigation and analysis of their impact on relevant metrics. Since a simulation model in these cases will comprise all equipment relevant to the plant or facility, interactions of the warehouse management algorithms with all other elements of the overall system are considered in such an investigation.

-

Digital twin simulation projects

-

Digital twin simulation projects focus on developing simulation models that interact with the actual PLCs controls to be deployed or already in use in operations. Actual PLC controllers receive signals from the simulation model while the PLC then returns relevant attribute values. For example, the simulation model will trigger a sensor when a pallet is registered. The PLC returns the current drive speed of the engine. Below figure highlights a digital-twin example for a conveyor line with sensor communication sent by the model to a PLC and drive speed communication received from the PLC by the model.

Simulation models are most frequently developed and applied to the following areas:

- High-bay storage systems with one or multiple stacker cranes in an aisle

- Flat-bay storage systems with one or more cranes

- Packaging lines

- Comprehensive logistics systems

- Container terminals in seaports