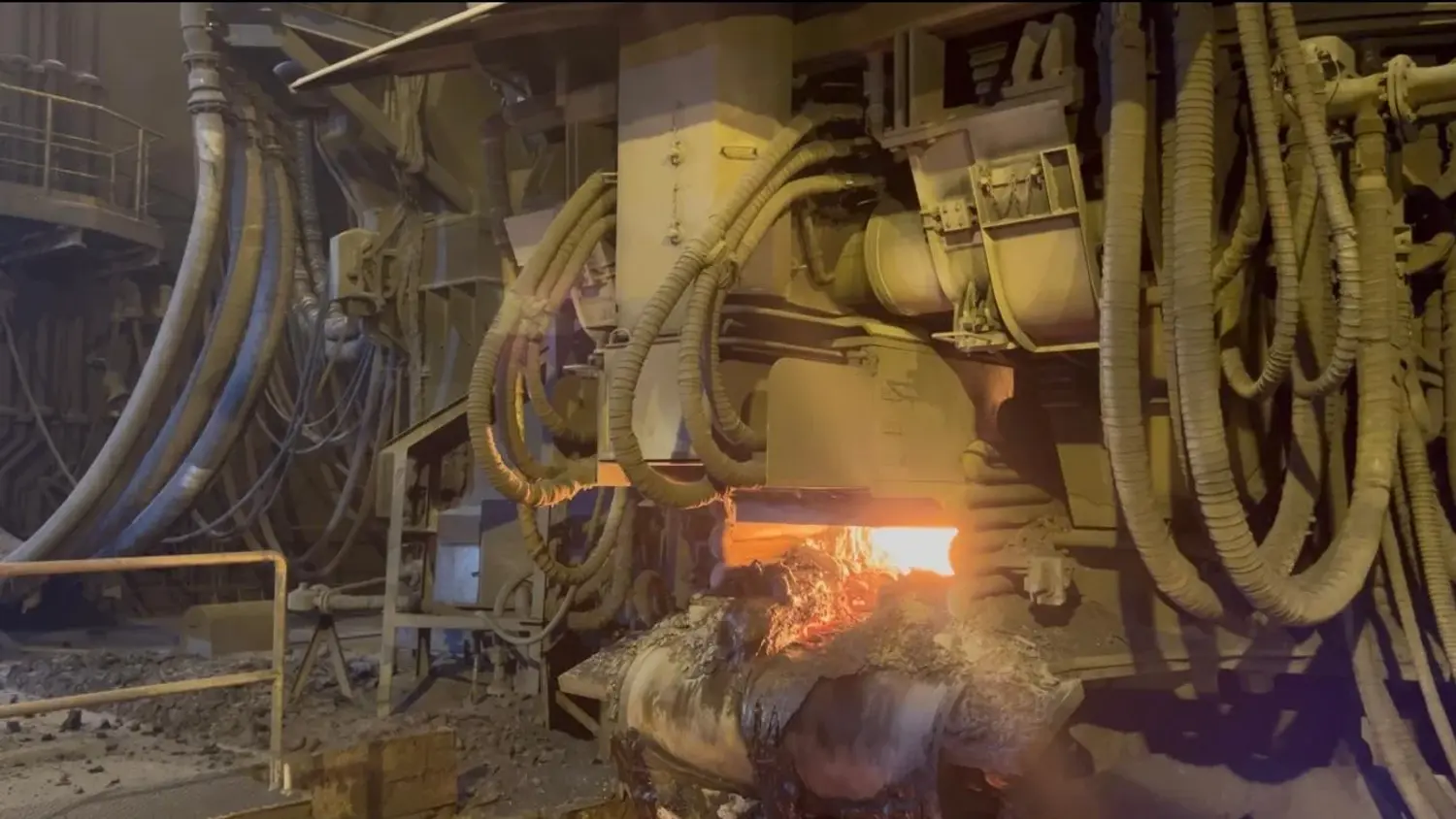

SMS has taken another step forward in the journey towards decarbonization with the successful implementation of advanced technology at SULB, a leading steel manufacturer based in Bahrain. The electric arc furnace (EAF) at SULB, with a 130-ton tapping size, has been equipped with state-of-the-art Condoor® system. Condoor® automatic slag door solution is a technology fine-tuned over the past 15 years by SMS and now, for the first time worldwide, a 100% Hot Direct Reduced Iron (HDRI) EAF operates in automatic mode, efficiently and safely handling the de-slagging process.

Project overview

The order for the Condoor® systems was placed in February 2023 with the first heat achieved at the end of August 2024, and the project successfully reached Final Acceptance Certification (FAC) on June 4th, 2025. This timeline reflects the seamless collaboration and precision planning required to implement such advanced technology into SULB's operation.

Condoor® system overview

The Condoor® technology enhances EAF’s performance and safe working practice through no man operation on the shop floor.

As an automatic slag door concept, the Condoor® system acts as a slag valve control, precisely managing slag volume and atmosphere within the EAF. This leads to reduced material losses, optimized energy consumption, and decreased electrode usage ultimately providing savings and improving process efficiency. Its adaptable design ensures compatibility for retrofitting existing installations, making it ideal for modernization projects. Additionally, the system accommodates all types of solid and liquid raw material charges, ensuring stability and repeatability in the melting process.

The Condoor® system has been instrumental in enhancing safety at the workplace by preventing people getting closer to the furnace during operations. Besides, furnace door bay always remains clean and hardly requires any further manual efforts, thus minimising potential risks while working in the area.

Long-standing partnership

Beyond the Condoor® systems, SMS had already supplied SULB with a steel melt shop, caster, and rolling mill and the successful implementation of the Condoor® systems underscores the enduring partnership between SULB and SMS, built on trust and a shared commitment to innovation. SMS provided continuous technical expertise and support throughout the project, ensuring the systems met SULB’s operational requirements and sustainability goals. Feedback from SULB allowed SMS to refine and optimize the Condoor® technology, reinforcing its position as an industry leader in steelmaking solutions. This comprehensive collaboration highlights SMS’s dedication to delivering tailored solutions that drive operational excellence and technological advancement.

Andrea Lanari, Vice President of Metallurgy at SMS group emphasized the significance of the project “Condoor system for the first time is in operation on a 100% HDRI EAF, confirming the original idea conceived years before: 'On a flat bath EAF, operating a sealed environment with proper control of de-slagging is key for the improvement of performances.' We will apply the same winning concept to all new furnaces under execution by SMS, part of the European decarbonization journey. A big thanks goes to our customer SULB, who believed in the concept and supported SMS in reaching the project's common target."