The new SDI Sinton complex is among the most advanced and comprehensive steel plant projects in North America. SMS group supplied the full scope for primary and secondary metallurgy as well as for hot and cold strip processing. The entire complex boasts an annual liquid‑steel capacity of over 3 million t. All components were integrated into the X-Pact® automation ecosystem, featuring a modular software architecture that interlinks all plant areas.

CSP® Nexus is the technological evolution of SMS group’s proven CSP® (compact strip production) platform with one crucial distinction: the complete decoupling of the continuous casting, roughing, and finishing mills. This real batch architecture provides, for the first time, control of all rolling phases with the flexibility and precision of conventional hot strip mills, while delivering a significantly more compact footprint and materially reduced energy consumption.

Technologically, the CSP® Nexus plant at SDI is far more than a compact combination of caster, rolling mill, and furnaces. It is designed as a fully decoupled, fully digitally controlled direct rolling process and, as such, opens up functional possibilities that until now were reserved for conventional hot strip mills. Each section of the plant is designed to precisely control temperature, time, and reduction profiles, aimed at producing a wide range of products at maximum energy efficiency and process stability levels.

Continuous casting with high throughput and optimum control

The process starts with a single-strand curved caster based on a vertical bending concept with liquid core reduction (LCR plus). The strand thickness ranges between 110 and 140 mm – much thicker than in conventional CSP® plants of 50 to 90 mm. The strand is cast at up to 6 m/min.

By contrast with other thin slab casting and rolling (TSCR) concepts, in which casting and rolling are necessarily linked, the process at CSP® Nexus is decoupled immediately after casting. A pendulum shear cuts the strand to the precise coil weight, then the material flow is buffered and purposefully transferred.

This transfer to the first furnace takes place at a high temperature level: The casting process itself has temperatures of around 1,150 °C, so no energy-intensive heating is required. The role of the first furnace consists rather in the temperature homogenization of the cross-section and in thermal fine-tuning for the subsequent roughing process. This furnace also allows the buffering of slabs during a work roll change without interrupting the casting process and provides the logistics to add a second strand to increase productivity.

X‑Pact® Dynamic Furnace Control, integrated into the CSP® line’s level 2 automation structure, precisely calculates set points for the furnace zone temperature to heat up the slab to the given discharge temperature at the appropriate heating time, acceleration point, and buffer time. The system supports heating and acceleration strategies to reduce energy consumption by lowering furnace zone set points where feasible and/or to increase buffer times by initiating slab acceleration as early as possible, all fully aligned with higher‑level control and planning functions.

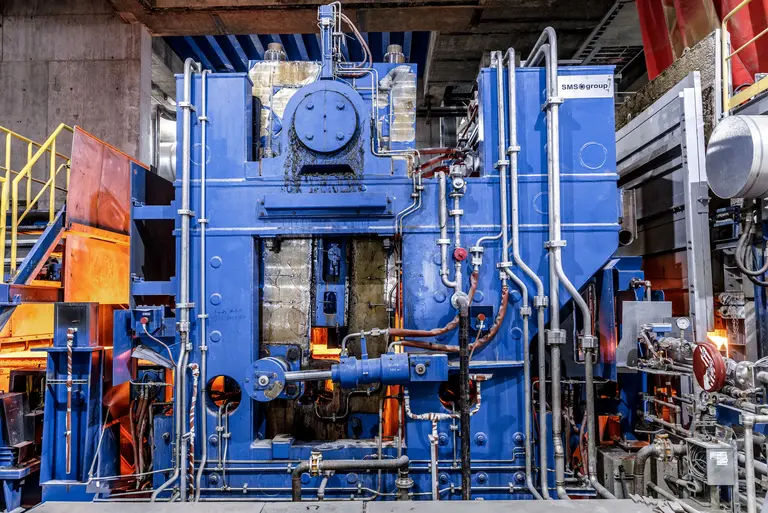

Two powerful roughers for maximum rolling speeds and reductions

The roughing mill area consists of two non-reversing roughing stands, supplemented by two vertical edgers for higher productivity and precise width control. The high reduction per rolling pass of the roughing mill ensures the penetration of the rolled slab to its core. The entry thickness is typically 110 to 140 mm, depending on product requirements, and the transfer bar leaves the second rougher with a thickness between 35 and 60 mm. The aim of the process is to achieve a maximum degree of deformation with the minimum processing time to keep heat losses low and to avoid energy-intensive reheating. A crucial advantage is that in real batch mode, the rough-rolling speed is not limited by the downstream processes. This allows rough-rolling speeds of up to 3.5 m/s, i.e., significantly higher than with continuous TSCR concepts involving coupled mass flows.

Thermomechanical and real batch rolling

The transfer bar then enters the transfer bar cooler, a special cooling device that provides accurate temperature control before finishing. This is essential for guaranteeing flexibility when producing micro-alloyed steel grades with high toughness requirements (e.g., API for line pipes). This is where thermomechanical rolling is employed, which requires a defined temperature drop after roughing but before finishing to achieve the desired microstructure.

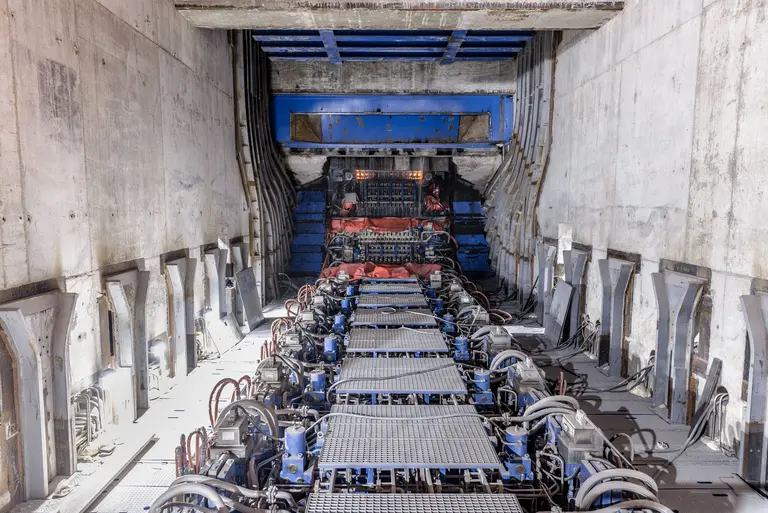

The transfer bar is conveyed over the second heated roller table. It acts as a central buffer zone between roughing and finishing. It allows:

- Complete decoupling of the two rolling phases.

- Independent selection of the finishing rolling speed for precise control of the final rolling temperature requirements for the relevant product.

- Homogeneous temperature profile over the length and width, and thus homogeneous final product properties.