Management information diagnostic indication system

Manage set-points and parameter for a fully automated production

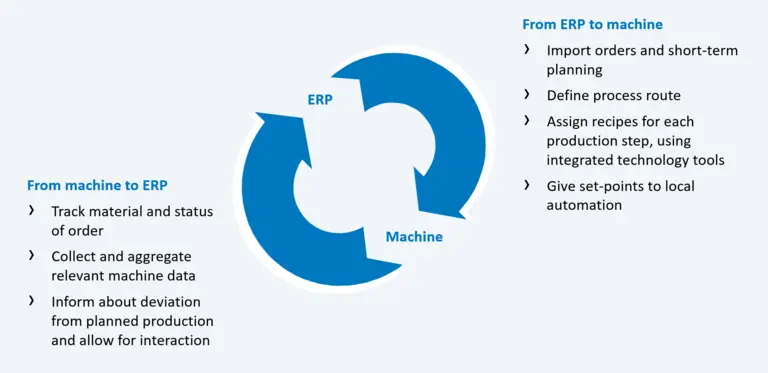

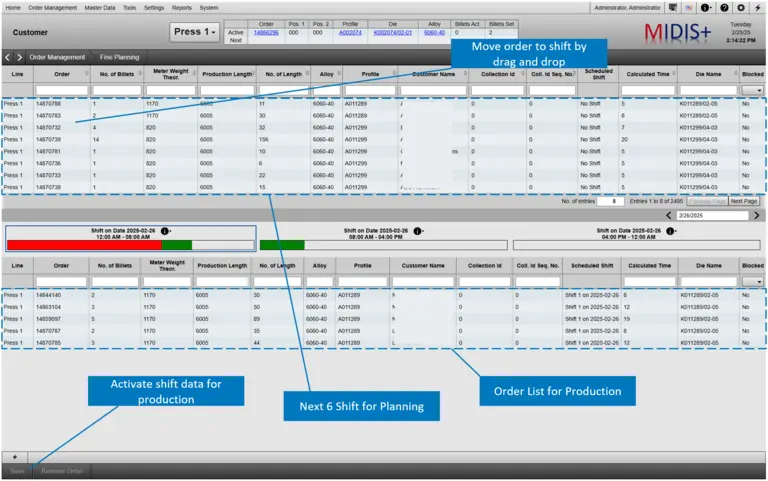

The integrated production planning system MIDIS® (Management Information Diagnostic Indication System) is designed to manage set-points and parameters for fully automated production across all areas of forging plants. This system seamlessly synchronizes machines within a production line, such as furnaces, shears, and presses, and is compatible with non-SMS equipment and various transport vehicles, providing a holistic management solution.

By utilizing SMS technology tools, MIDIS® generates optimized production and transport instructions, significantly enhancing operational efficiency. As a state-of-the-art web application, it offers modularity and flexibility, allowing it to adapt to specific production requirements. The system includes workplace-specific Human-Machine Interfaces (HMIs) for enhanced usability and employs a unified database, increasing awareness of plant efficiency and production scenarios.

This makes MIDIS® an ideal solution for manufacturers aiming to optimize processes and maintain a competitive advantage.

Let's get in touch!

Use our contact form for questions, inquiries or personal contact.

Management of interruptions, tools and materials

Create data basis for further evaluation

Interruptions

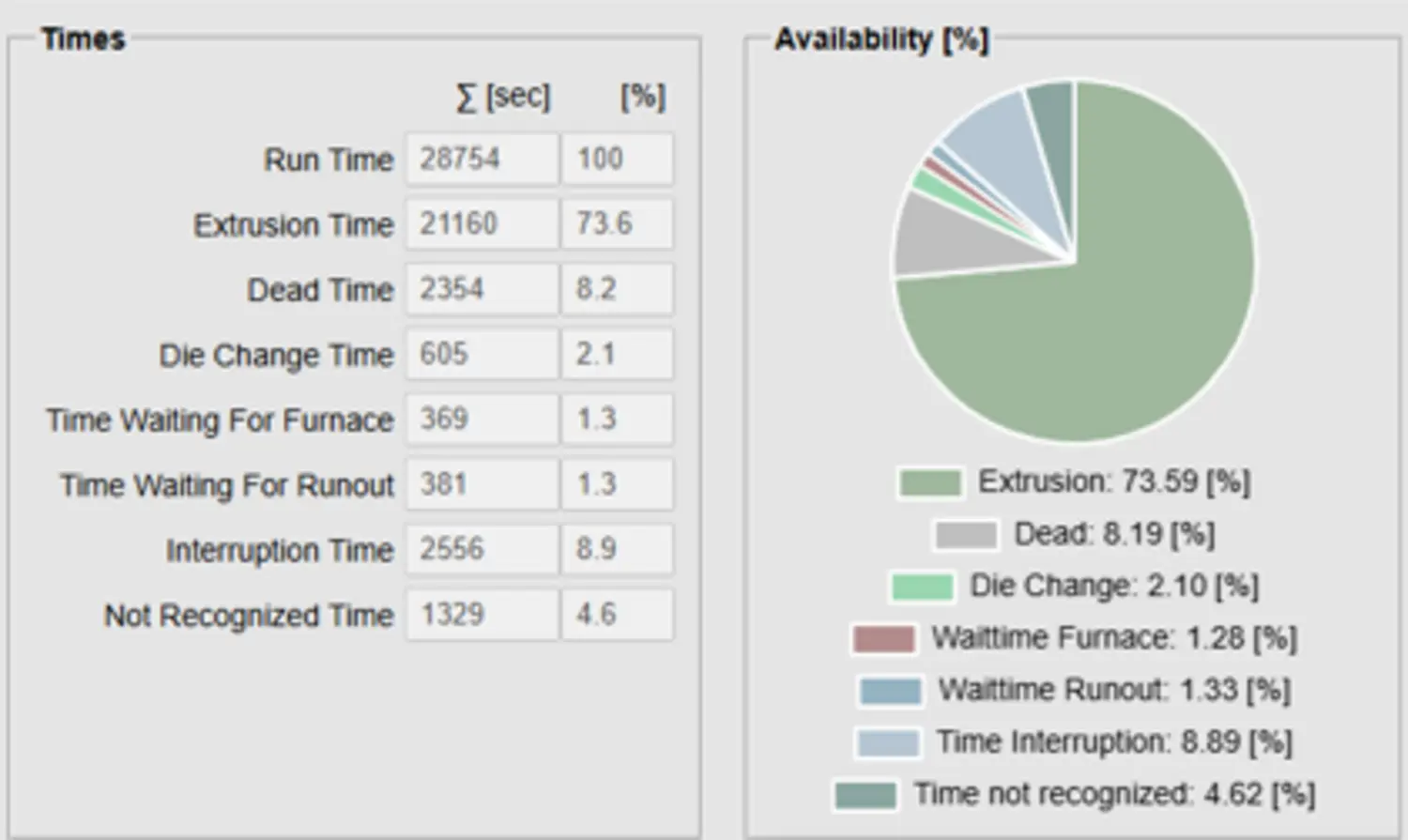

MIDIS® enhances productivity by precisely tracking and analyzing interruption times. It automatically logs start and stop times from the PLC, allowing users to assign reasons from a predefined list for clear and accurate documentation.

Tool management and order history

This feature focuses on extending tool lifespan by tracking usage and storing tool change times. Users select tools from a predefined list for each production run, while the system automatically records production metrics like billet count, weight, and length.

Materials and alloys

MIDIS® standardizes production with harmonized alloys, storing machine-specific parameters for each alloy, such as cooling and saw settings, to ensure consistent quality and efficient processes.

Benefits

- Higher production due to standardized processes and high degree of automation

- Better transparency by using standard reports for production, quality, energy and maintenance

- Improved efficiency by collecting tool usage and production data

- Higher delivery reliability and better planning through evaluations of the production from the order to the material dispatch