Operators of hot strip mills or heavy plate mills face operational challenges in oil lubrication systems. While their impact on product quality is often indirect, the efficiency of these systems directly influences operational costs and plant reliability. Despite their importance, the optimization of oil system design and maintenance has frequently been overlooked, leading to significant inefficiencies. These inefficiencies manifest as oversized oil systems, overloaded return lines, and persistent issues like losses of lubrication oil and water ingress, which can severely disrupt production processes.

Oil losses in brownfield hot strip mills or heavy plate mills, for instance, can reach staggering levels of up to 500,000 liters per year. Similarly, water ingress into oil lubrication systems - often caused by faulty seals or cooling units - can push water content beyond permissible limits, resulting in forced production stoppages. Maintenance teams, under time pressure, often resort to ad-hoc solutions like seal replacements based on gut instinct, rather than addressing the root cause of the problem. Such reactive measures not only fail to resolve the underlying issues but also lead to increased operational expenditure (OPEX) and reduced plant efficiency.

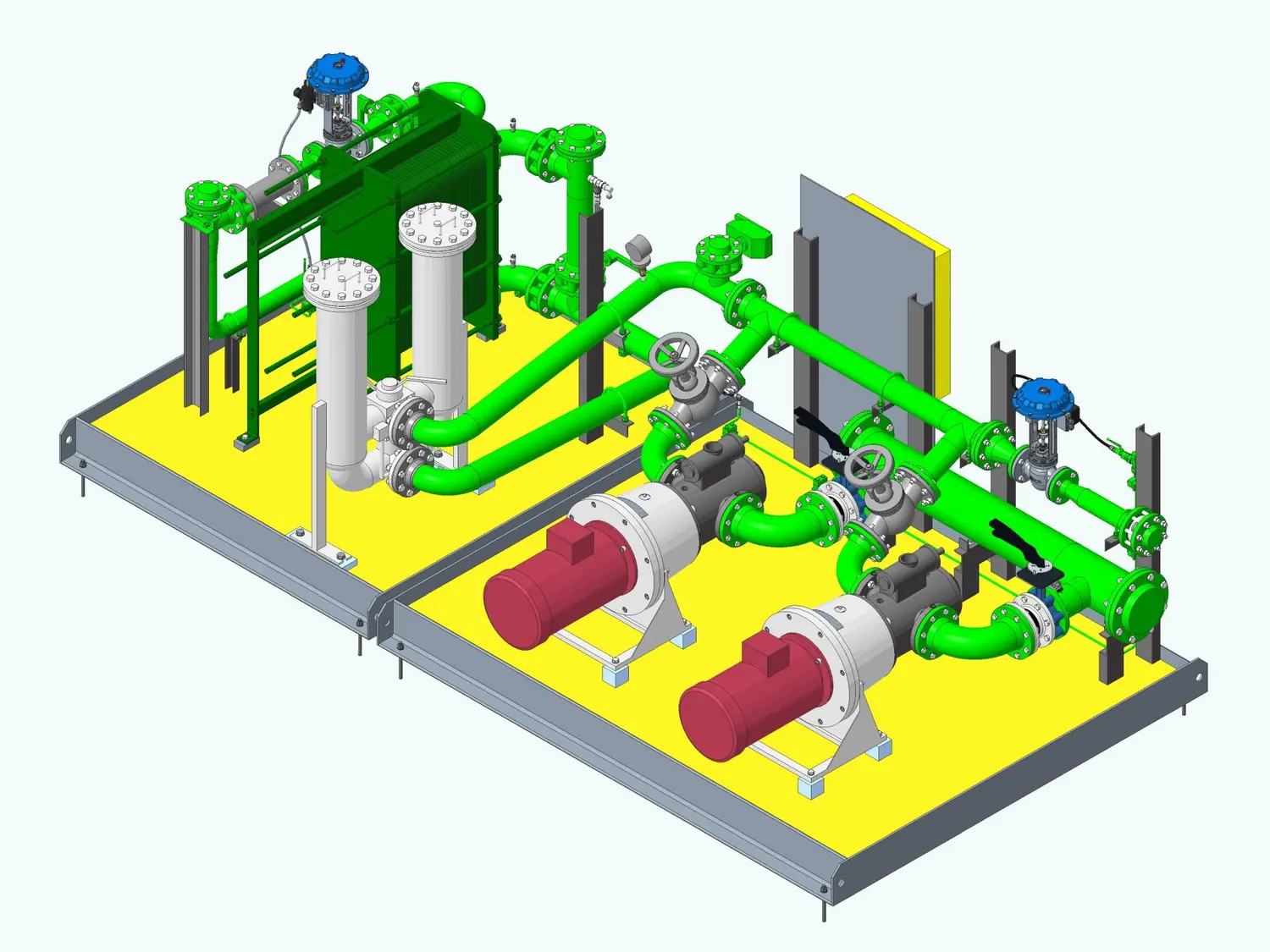

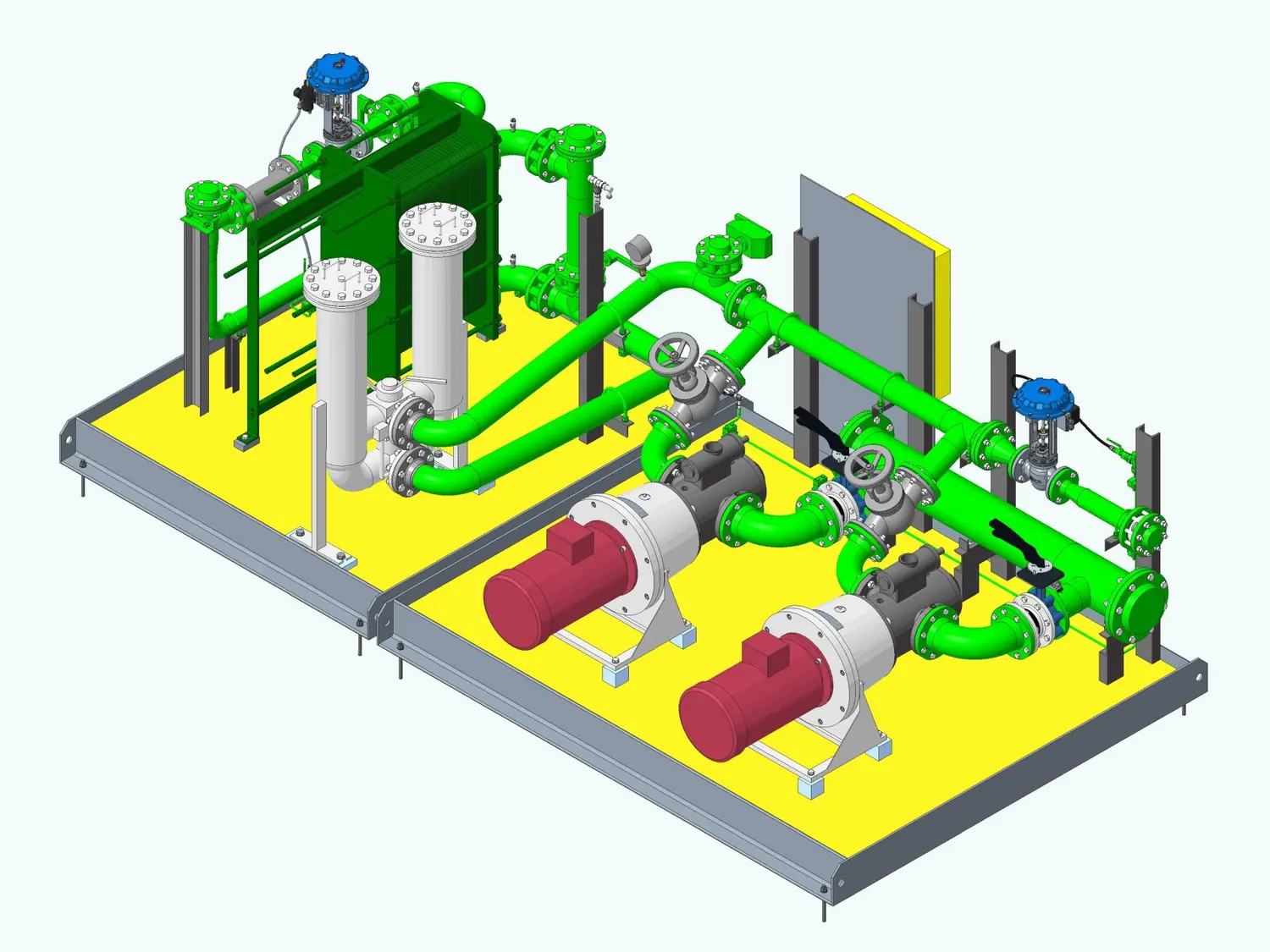

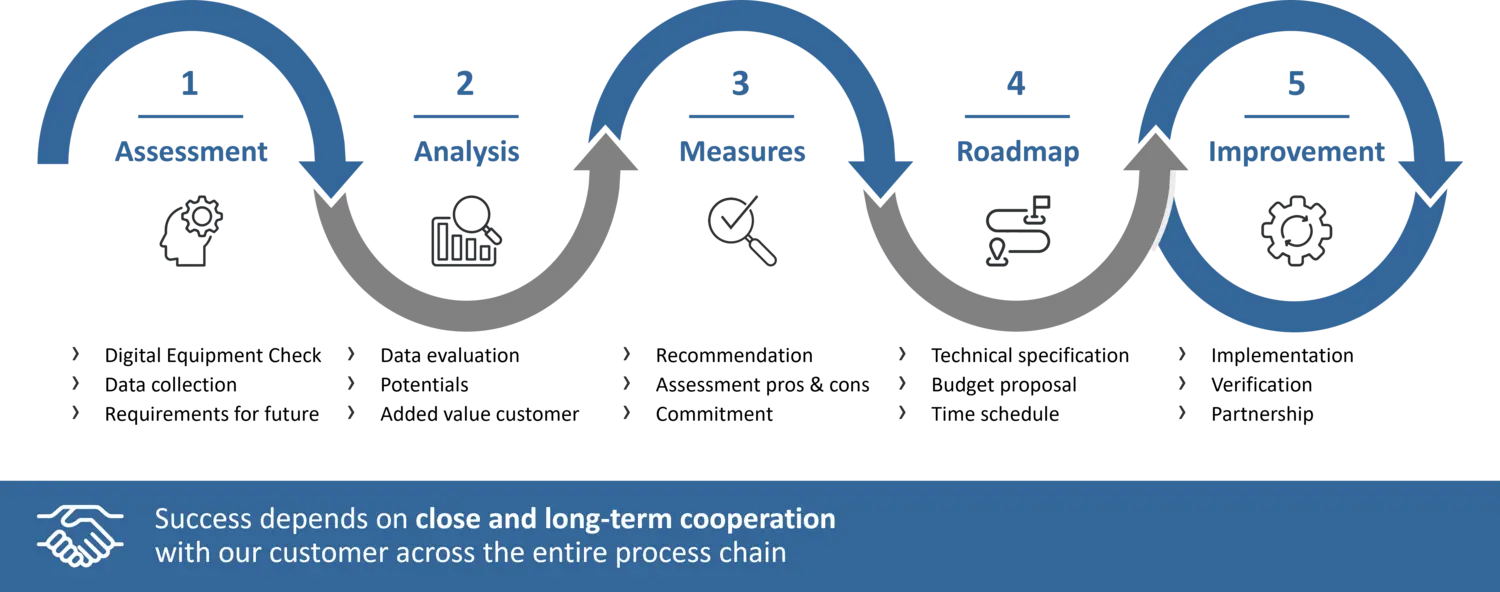

This is where the Oil System Assessment proves invaluable. By conducting a thorough on-site evaluation, SMS group experts identify hidden inefficiencies and propose targeted solutions. The assessment begins with a detailed analysis of data from existing systems, combined with precise measurements to uncover inadequacies that might otherwise remain invisible. From there, the team evaluates the facility's design and operating parameters, pinpointing areas that require adaptation or redesign. This holistic approach ensures that oil flow rates, pressures, temperatures, and viscosities are optimized to meet actual operational needs, rather than relying on outdated assumptions or safety factors.

Assessment of oil lubrication systems reduces oil losses and improves oil quality

The benefits of a timely assessment of the lubrication oil system are significant. Reduced oil losses, improved oil quality, achieved by reducing water content and minimizing contamination, enhances lubrication performance while extending the lifespan of the oil. Energy consumption decreases as optimized flow rates reduce the load on pumps, cooling systems, and heating units. Maintenance costs are lowered through predictive strategies that prevent unnecessary seal replacements and reduce spare part consumption. Most importantly, plant availability is increased, minimizing downtime caused by oil-related issues and enabling smoother production processes.

For customers, the advantages extend beyond operational efficiency. By addressing lubrication oil losses and water ingress proactively, businesses can achieve substantial cost savings while aligning their processes with environmental regulations. The tailored roadmap provided by SMS group experts ensures that the recommended measures are implemented seamlessly, without disrupting ongoing production. Ultimately, the Oil System Assessment represents a strategic investment in quality, efficiency, and productivity - empowering rolling mills to operate at their full potential while reducing OPEX and safeguarding long-term reliability.

Timely action is key. With the Oil System Assessment, customers gain access to cutting-edge expertise, actionable insights, and tailored solutions that address their facility’s unique challenges. By choosing to act now, businesses can prevent costly inefficiencies and unlock the full potential of their oil lubrication systems, ensuring a more sustainable and profitable future.

More information on our oil system assessment

Learn more about the assessment and get in contact with our experts.