Due to the high contact stresses between the railway vehicle wheels and the rails, the latter are subject to wear and fatigue damage caused by the roll contact force. Rails are the main cost driver when it comes to railway network maintenance. Rail manufacturers are making efforts to improve rail durability by optimizing the microstructure in the contact area between the wheel and rail, resulting in head-hardened rails (HHR) that have a significantly longer service life. In almost all rail manufacturers’ production facilities, this requires an inline heat treatment procedure directly after rail hot rolling. The main advantages of this arrangement are the exploitation of the heat from the rolling process and the resulting shorter process chain, as the rail does not need to be separately heat-treated.

Rail head hardening with innovative RailCool® Pure Air

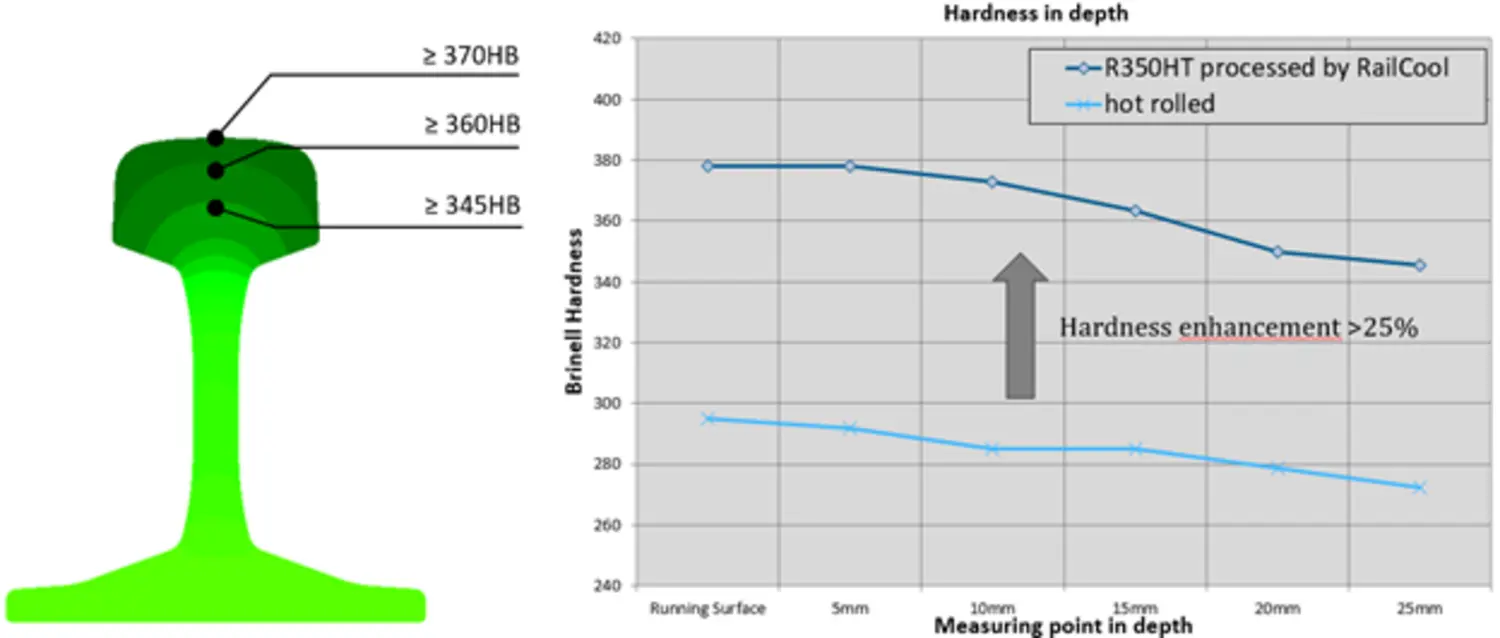

RailCool® Pure Air is designed to optimize the material’s microstructure so that the mechanical properties of the rail heads, including the hardness and tensile strength, can be considerably enhanced. RailCool® Pure Air uses air to ensure consistent and reproducible cooling that creates a fine pearlitic microstructure in the rail head. Unlike with water, which can often result in excessive cooling, RailCool® Pure Air provides temperature-controlled “soft cooling” at a cooling rate of two to three Kelvins per second. A major benefit of air cooling compared with water is the ability to precisely measure temperatures and, if necessary, adapt the cooling rate accordingly, thus ensuring ideal conditions. In conventional rail manufacturing, a continuous pass cooling process is used. The problem here, however, is that the rail end moves faster through the production process than the rail head, which means that parts of the rail have already cooled down before the production sequence can be completed. To compensate for this, an induction heater is required, which makes the process more complex and energy-intensive. With RailCool® Pure Air, this problem is solved using a static technique. The air-based cooling system ensures that cooling takes place evenly over the whole length of the rail. This innovative method eliminates the disadvantages of the conventional continuous pass cooling process and facilitates more efficient and resource-saving rail production. Compared to conventionally head-hardened, rails made with RailCool® Pure Air boast a up to three service life. Additionally, they also reduce wear and minimize maintenance requirements, especially in environments with high contact stresses between wheels and rails. RailCool® Pure Air simplifies the rail production process, improves quality such as rail straightness, and removes residual stresses in the microstructure.

Achieving consistent rail production quality thanks to air-based temperature control

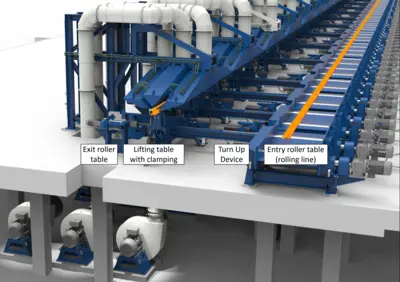

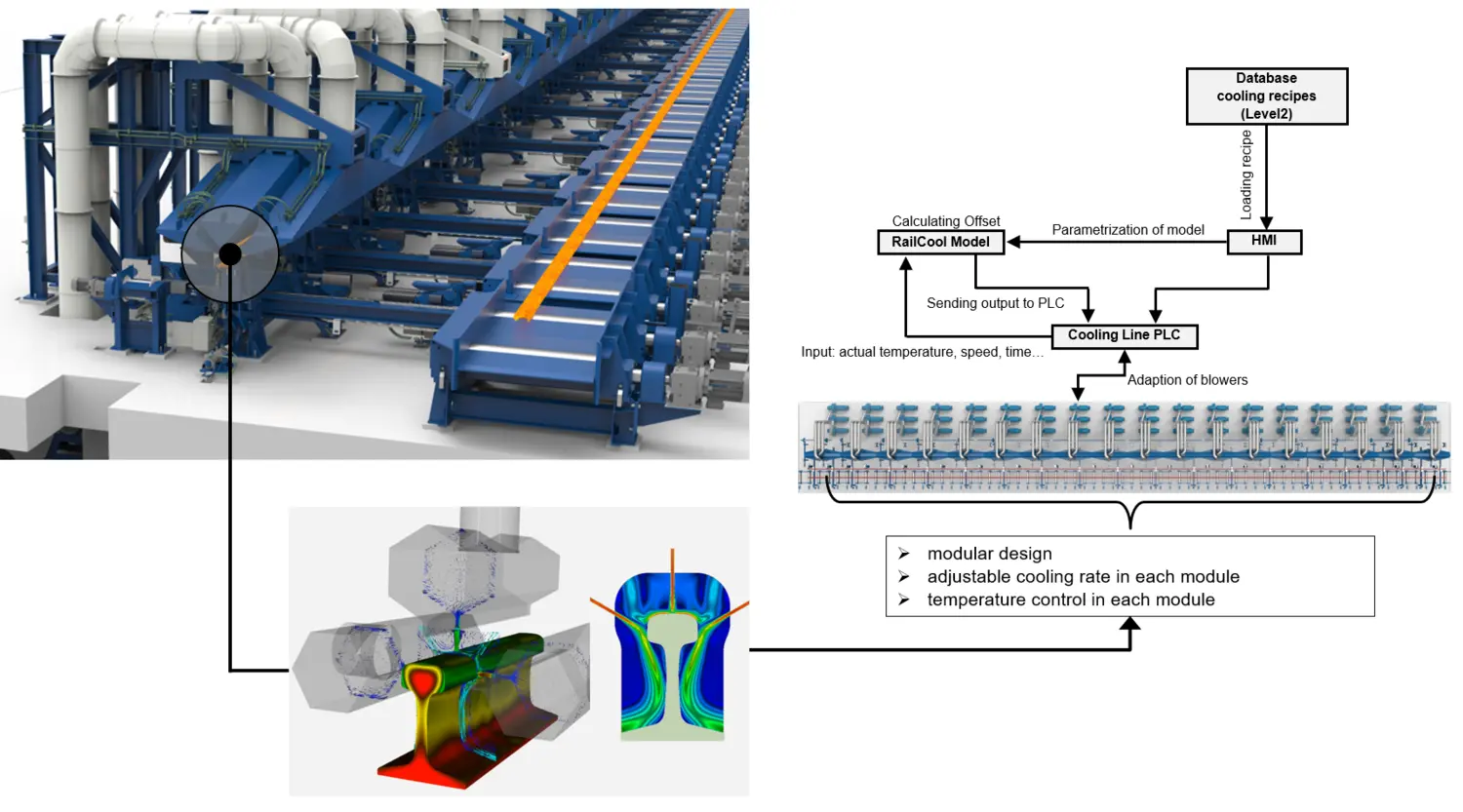

After the rolling process, the rail is transferred to the RailCool® Pure Air area and moved into an upright position. Alignment devices ensure that the rail is precisely positioned during heat treatment, thus guaranteeing homogeneous and effective cooling. The RailCool® Pure Air modules for heat-treating the rails use large quantities of air to achieve uniform cooling and eliminate any inconsistencies. An uneven temperature distribution along the rail length (like with the water-based rolling processes) can be compensated by RailCool® Pure Air modules that are individually set up and controlled. In each module, a selective cooling method is applied to homogenize the temperature in different areas of the rail head. In addition, an integrated technological model is employed to automatically control the temperature of the rail during the process and to adjust the cooling rate using a pyrometer based on the actual temperature measured. Consequently, the rail is heat-treated with the optimum cooling strategy. This dynamic adjustment of the cooling system according to the optimum temperature curve ensures that the relevant rail quality requirements are met for a variety of different steel grades, standards, and sizes. RailCool® Pure Air offers full operational flexibility and allows cooling procedures to be easily adapted to meet specific production demands, while assuring consistent product quality.

RailCool® Pure Air: Sustainable rail head hardening technology for new and existing facilities

In rail production, the RailCool® Pure Air marks a significant step forward in terms of efficiency, durability, and sustainability. By integrating RailCool® Pure Air after the rolling process, it eliminates the need for an induction heater by using the residual rolling heat directly for hardening. This integration reduces the energy required and avoids the energy-intensive re-heating step entirely, which means considerable CAPEX and OPEX savings.

RailCool® Pure Air acontributes to a smaller lifecycle CO₂ footprint, thanks to reduced electrical re-heating and the avoidance of energy-intensive water treatment systems. The solution completely avoids water and chemical additives and instead relies on air-based cooling, which means no water treatment system is required.

RailCool® Pure Air is not only suitable for new rail mills, but it can also be flexibly integrated into rolling mill facilities currently in operation. The compact design of the system reduces the space required for the layout, which is limited in existing works. Depending on the design, the installation can be carried out without having to halt production, thus largely reducing downtimes.

Spearheading the future of rail manufacturing with RailCool® Pure Air

RailCool® Pure Air represents a leap forward in rail head hardening and offers numerous advantages in terms of durability, maintenance, and process efficiency. The innovative use of forced air cooling sets a new standard in the industry and makes it a truly valuable asset for rail manufacturers.