Why optimal strand cooling is crucial

Secondary cooling in continuous casting plants plays a significant role in determining both the quality of the final product and the energy efficiency of subsequent production steps. If cooling is not optimized, the risk of cracks and unwanted stresses in the strand increases, which negatively affects the metallurgical properties and, in particular, the internal and surface quality of the steel. In addition, different steel grades, changing formats, and varying environmental conditions require stable and efficient secondary cooling. This calls for a highly advanced process model that can anticipate and respond flexibly to changes.

SMS group began developing secondary cooling models as early as the last century and has continuously refined them – from the simple, speed‑proportional cooling model, through strand‑age‑based approaches and simplified 3D temperature models, to today’s X‑Pact® Solid Control. The result is a consistently proven process model that integrates seamlessly into plant automation and accurately reflects real operations in all their complexity. This enables steel producers to control the casting process in the best possible way.

Highlights of X Pact® Solid Control

X‑Pact® Solid Control is a process model for the optimal cooling of the strand, with the aim of ensuring product quality, maximizing production, and minimizing energy consumption in downstream processes.

The model is divided into two packages:

Technology package

The technology package provides a comprehensive toolbox for the metallurgist and supports the determination of the optimal cooling strategy for each steel grade. It includes the following modules:

- Material center: Stores comprehensive steel grade information, including chemical composition. From this data, it calculates thermophysical properties, phase transitions, hot‑cracking susceptibility, scale growth, and time‑temperature‑transformation diagrams. In addition, around 90 ductility curves are integrated to enable detailed analyses of material properties.

- Assistants: Supports the creation of grade‑dependent reference temperature curves, spray plans, air plans, factors for width, spray water temperatures, superheat temperatures and reduction ratios for Dynamic Soft Reduction®.

- Tech assist: Stores and manages the determined technological process parameters.

- Simulation: Simulates the casting process considering specific plant parameters such as roller plan, roller carpet, as well as nozzle arrangement considering different nozzle types, their spray angle and their geometric position in the strand guide.

- Replay: Enables the analysis of recorded production data for further optimization.

- Defect analyzer: Uses laboratory results from crack investigations to identify and display the origin of crack formation within the strand guide. Therefore, targeted countermeasures can be derived.

Process package

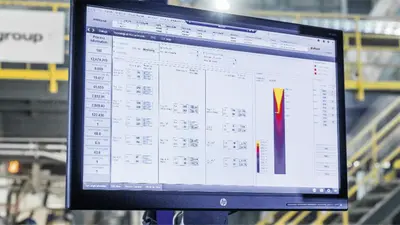

The process package is designed for the operator and is fully integrated into plant automation. It contains only the essential information required to monitor the casting process (strand temperatures along machine length and width, solidification front along strand width, growth of strand shell along machine length, water quantities in the individual control loops). As the model runs autonomously, an operator intervention is not required.

X‑Pact® Solid Control is an innovative and powerful solution that combines in‑depth metallurgical expertise, precise simulation technology, and seamless integration into plant automation, providing steel producers with an outstanding tool for process optimization.

The advantages are clear: Quality can be optimized through a wide range of settings, which also ensure reproducibility of results. Production can be efficiently increased, for example, by targeted optimization of the position of the solidification point. In addition, an optimized cooling strategy helps to achieve the highest possible exit temperatures, thereby reducing energy consumption in downstream processes. X‑Pact® Solid Control thus not only enables improved process control but also supports long‑term sustainable competitiveness in the international steel market.