AI optimized product changes at cold rolling mills

Our integrated technological solution autonomously provides the optimal strategies for all product changes at cold rolling mills.

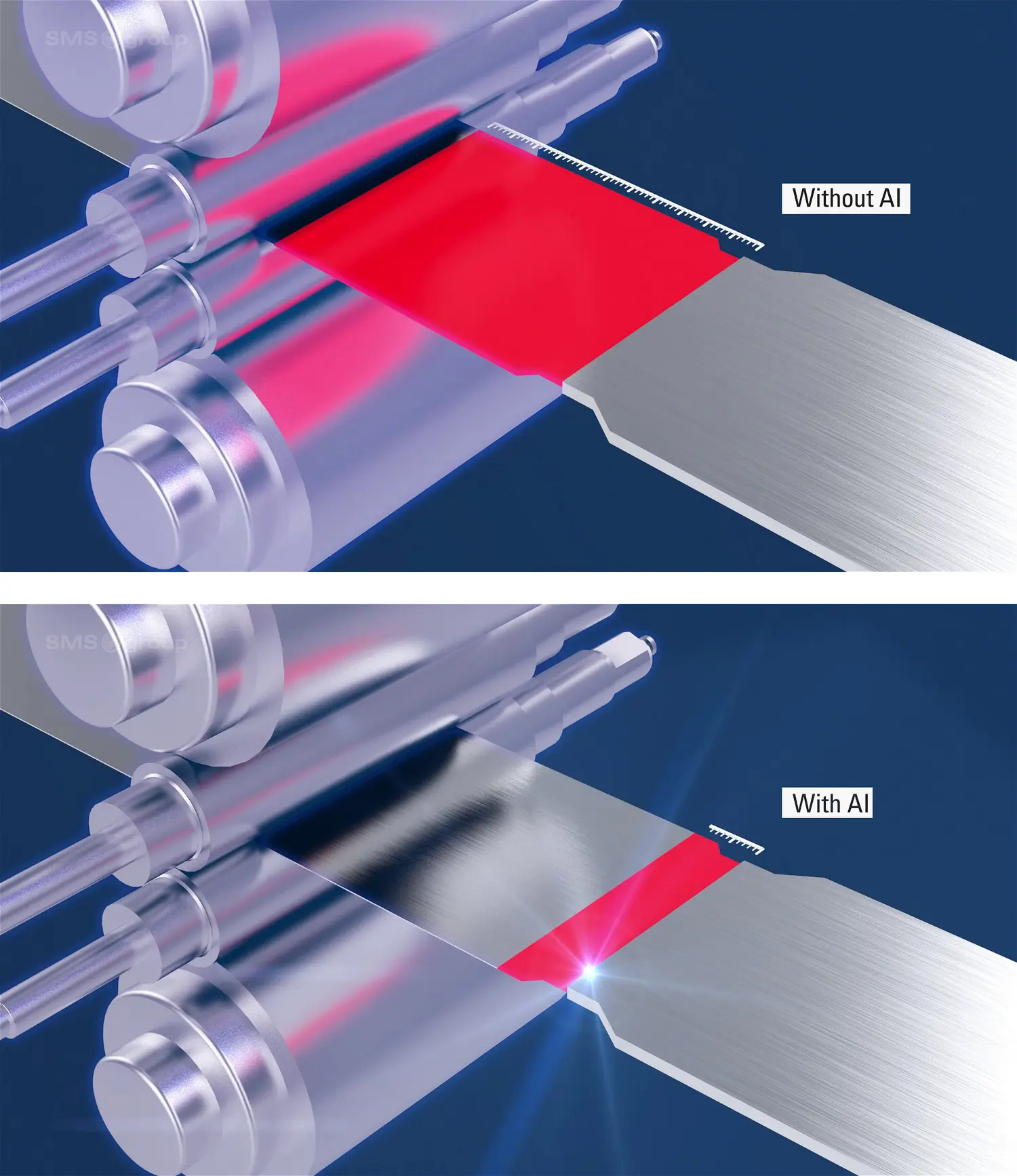

By utilizing an advanced machine learning approach, X-Pact® Superior Control generates precise setup values for the automation system, reduces off-gauge lengths while boosting yield within product changes.

Typical quality parameters, such as strip flatness and thickness tolerances, are improved, empowering plant operators to achieve superior operational efficiency.

Customer challenges addressed

- Achieving the target thickness and flatness after product changes

- Ensuring production quality and efficiency regardless of operator experience

- Overcoming the limitations of individual working level 1 and level 2 controls

- Enhancing the flexibility of production planning

- Managing material variations while maintaining product quality and minimizing waste

- Implementing self-optimizing controls to move toward autonomous plant operations