Automated extrusion line for heavy metal with reliable hydraulic design

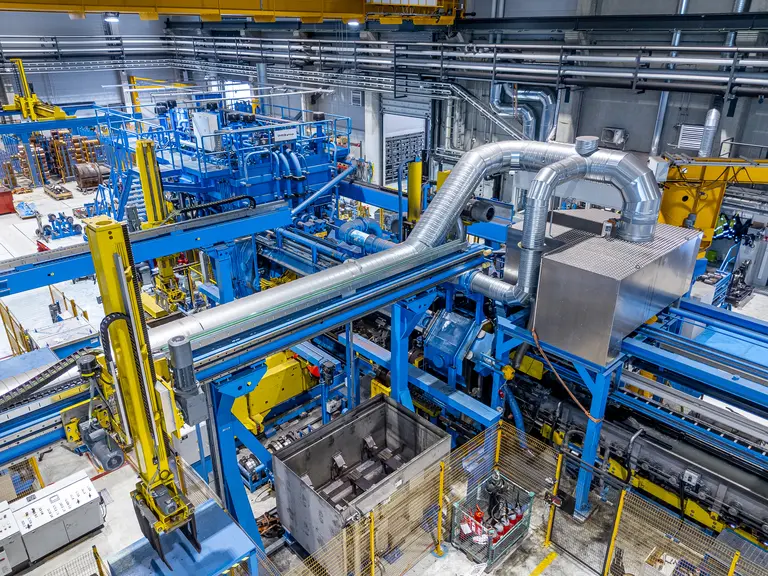

SMS group has designed and delivered a highly automated 55 MN direct/indirect extrusion press and complete hot extrusion line to Luvata’s Pori plant in Finland.

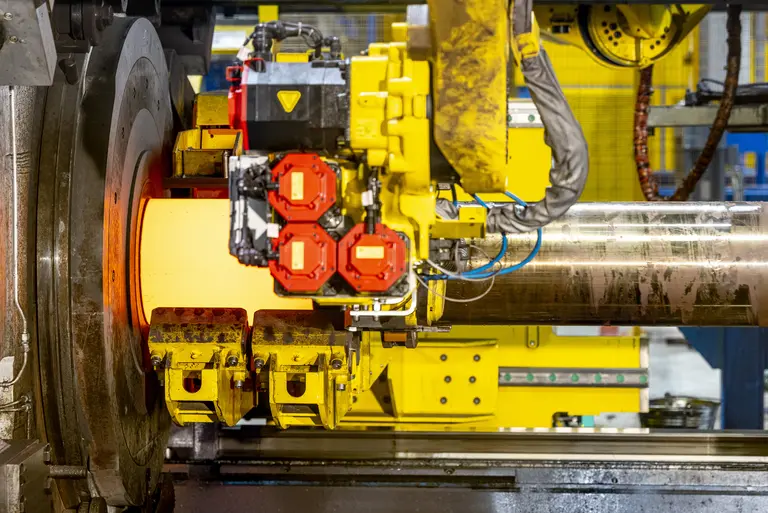

SMS’s latest hydraulic system design delivers the 55 MN force reliably, supporting both the power and precision required for heavy metal extrusion.

The new installation delivers a 75% performance increase over the previous SMS press and is engineered to meet the growing demand for higher extrusion power and alloy flexibility, including copper, nickel, silicon, chrome and dispersion strengthened DSC alloys. Combining direct and indirect extrusion capabilities in a single press, the system achieves dead cycle times of 48 seconds for direct extrusion and 55 seconds for indirect extrusion, enabling significantly higher throughput across a wide product mix.

The line is fully automated and equipped with four automatic handling systems, robot handling of loose dummy and scavenger blocks, automated cleaning and lubrication robots, and a fully automatic die change system.

Billet handling is fully automatic with precise positioning for frontloader operation. Inductive preheating brings billets to extrusion temperature and automatic descaling prepares material for processing, while continuous monitoring with PICOS ensures stable process control and consistent product quality.

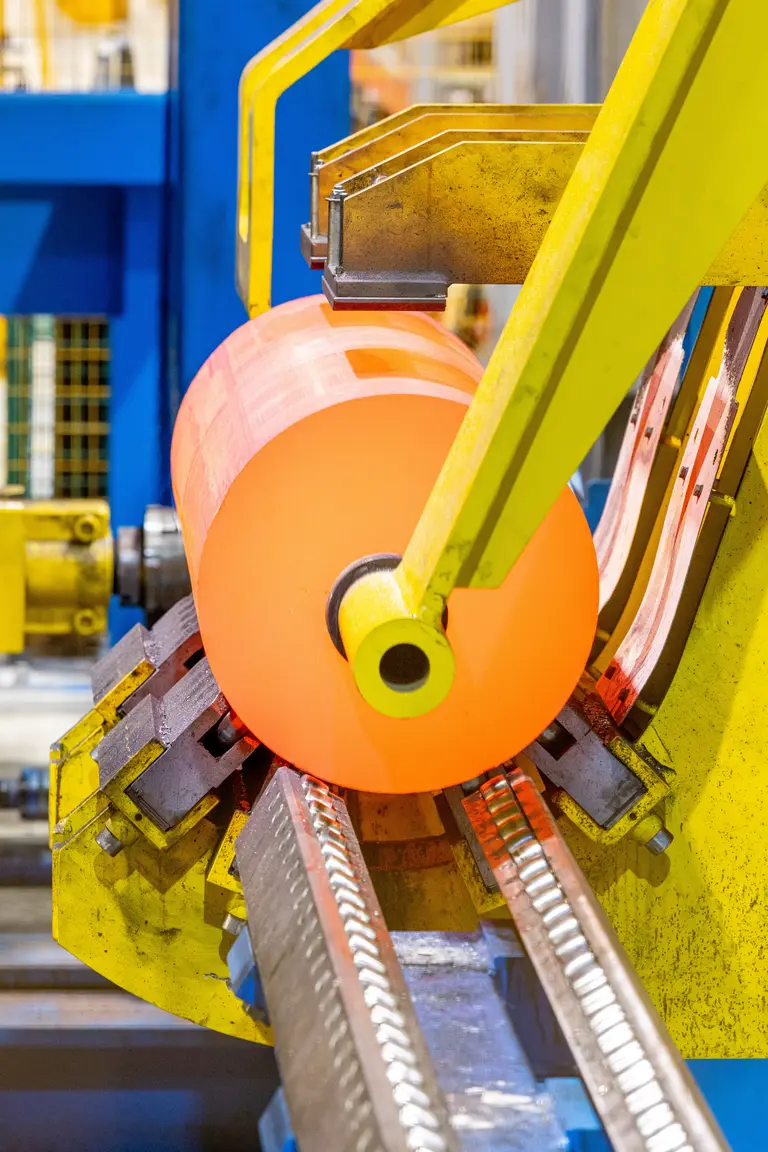

Flexible runout solutions include a vertical coiler capable of coiling at up to 6 m/s as well as a straight runout system for extrusions up to 40 m and a high‑performance finishing saw for profiles up to 17 m.

The result is a future‑ready extrusion line that combines hybrid press technology, advanced automation and comprehensive handling and monitoring to boost throughput, enhance operational safety and ensure long‑term precision and performance for Luvata.

Impressions

Main data

- Pressing force: 55 MN