How can the steel producer maximize yield, cut waste, and meet strict sustainability targets? Many operations contend with excessive scrap at side trimmers, a lack of systematic methods to define and apply width offsets, inefficient resource use, and asymmetric seams caused by centering performed too far upstream. To address these issues, SMS group introduces the Width Offset Minimizer — a combined hardware and software solution using a data-driven approach to reduce strip width offsets and minimize side-trimming scrap.

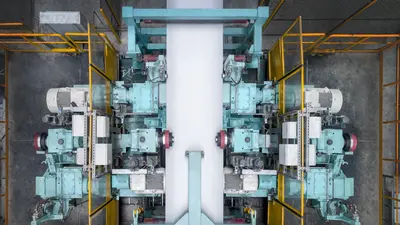

The system positions a high-precision optical strip-edge sensor directly at the side trimmer of the pickling line / tandem cold mill (PL/TCM) to detect geometric deviations precisely where they matter: in close proximity to the rotary knives. Local automation dynamically adjusts strip positioning in real time, while a predictive model computes the optimal width offset and communicates the recommendation to upstream controls in the hot strip mill (HSM).

High yield gains with minimal integration effort

Positioning the sensor at the side trimmer ensures consistent, symmetrical seams and enables the optimization of scrap reduction. The data-driven model and closed-loop control deliver tangible cost reductions through lower scrap generation and improved raw-material utilization.

As a standalone, modular package, the Width Offset Minimizer can be integrated into brownfield sites with minimal disruption, supporting immediate productivity gains and long-term sustainability targets.

The solution is equally relevant for new plants. The implementation in the new SSAB Luleå cold rolling complex will demonstrate how targeted digital innovation can produce immediate yield improvements and lasting environmental benefits for modern strip production. The solution’s digital backbone in this project, including X‑Pact® automation, AI‑assisted process models, Genius CM® Chatter Plus, and the SMS DataFactory, provides centralized analytics and actionable KPIs for faster, evidence‑based decision making. Deployed together, these technologies streamline material flows, improve product quality, and enable predictive, data‑driven operations that reduce both downtime and trim losses.