Shaping the future – converter steelworks from SMS group

Since the early 1950s, SMS group and its predecessor companies have been using their know-how for highly productive and modern converter steelplants for carbon and stainless steel worldwide.

SMS group is one of the leading companies in this market and meets the growing demands of its customers with advanced and reliable mechatronic systems. In cooperation with universities and institutes, eco-friendly and economical solutions are developed that are used worldwide.

The product range is wider than ever. This includes complex BOF and AOD converter steelplants with a high degree of automation and digitalization, as well as new paths in the metallurgical process and modernizations. Our solutions are durable and sustainably reduce maintenance costs. Tailor-made maintenance procedures, customer-specific training programmes and effective spare parts management round off our range of services. SMS group Technical Services is your contact for this: Service packages tailored to your requirements are available worldwide.

-

Oxygen steelmaking

Efficiency for you

Our experts are passionate about converter steelplants. We join forces with you to work together in partnership, always finding the best possible solution. We are at your disposal to help you achieve your goals. With our tailor-made solutions, you set new performance standards with your converter steelwork. We have gained our experience and a great deal of know-how in many projects and references. This enables us to tailor our solutions precisely to your processes and specifications. Our comprehensive portfolio is constantly being further developed and expanded. Our technologies increase your productivity, process quality and process reliability.

Stability and quality

Our experts, as well as a strong R & D department and advanced engineering tools, are crucial to our excellent design. This enables us to plan complex plants and modernizations and to implement them successfully. Our customers give us feedback that our designs lead to reliable and efficient systems. Because our technology also ensures long equipment and component life. Some SMS group converters have been operating for more than 40 years and are still running smoothly. Our customers appreciate this continuity and our quality. -

CONPRO

The hybrid furnace

SMS group has developed a new primary smelter called CONPRO in response to rising CO2 emission costs, fluctuating prices of charge materials for the BOF converter process, and anticipated increased scrap availability.

CONPRO integrates BOF converter and electric arc furnace technologies to provide an efficient and flexible energy source combination.

CONPRO can operate like a BOF converter, allowing for a reduction in the use of scrap or other coolants to about 15%. It uses a top lance and side wall lances for oxygen introduction. If molten pig iron is unavailable, or its production is ceased, CONPRO can seamlessly switch to electric arc furnace mode within a single shift, with only minor procedural differences from the BOF mode.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

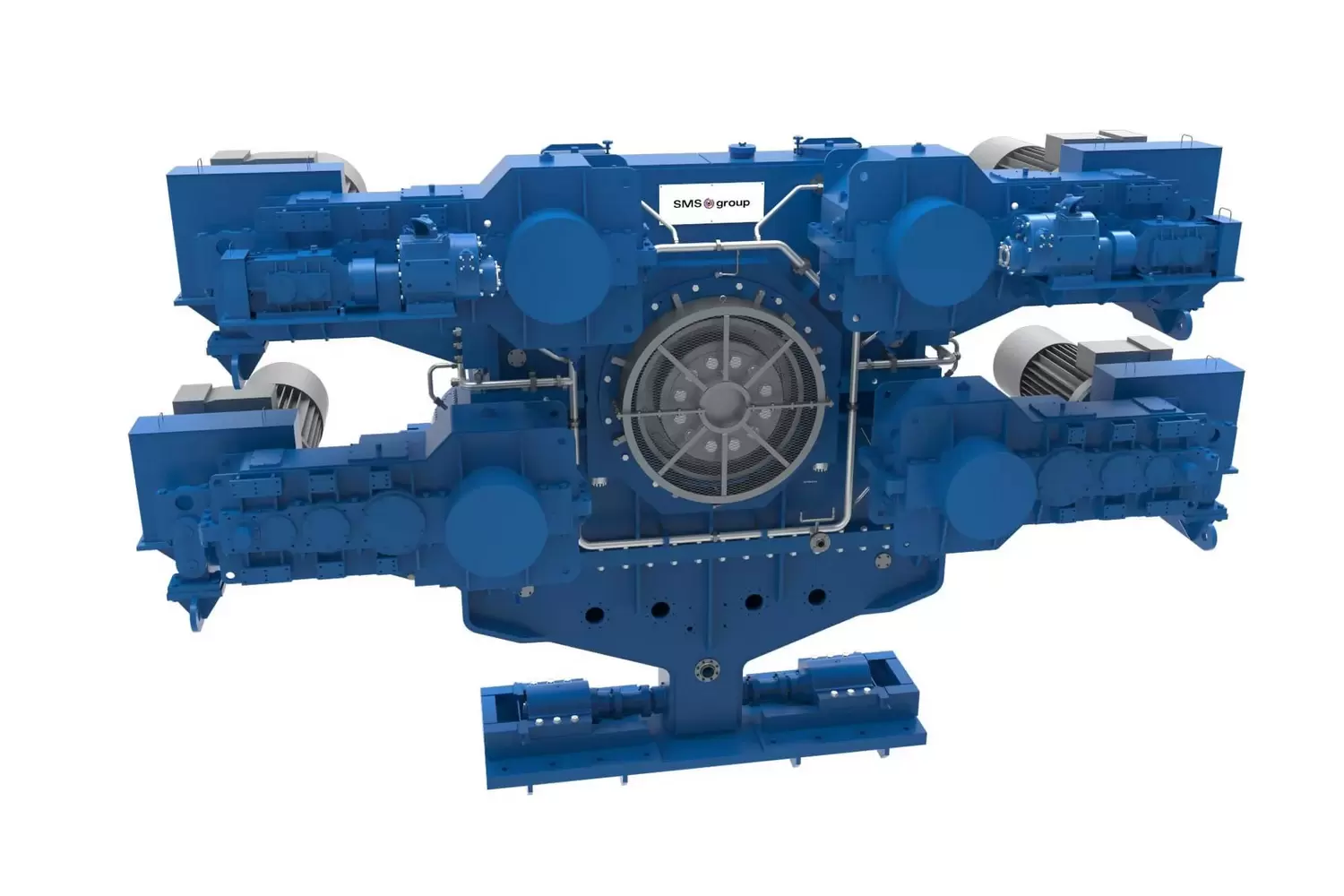

Tilt drive

A well-made tilt drive made in the SMS group workshop in Germany exceeds the basic function of just turning the vessel: It provides superior process control, reliability and maintainability. SMS group tilt drives can be seamlessly integrated in a Genius CM® condition monitoring system in order to require even less attention by plant maintenance personnel.

Highlights

- Advanced gear design and optional case hardening of bull gear result in higher safety and smaller footprint

- Highly customizable for tilting speed, acceleration, arrangement, etc.