Heavy plate plays a major part in future-oriented industrial applications and in the energy sector. Throughout its long lifetime it has to deliver customer value. In particular, SMS group, as the market leader for heavy plate mills and Steckel/Plate mills is observing an increasing demand for high-quality plates among its customers and is able to offer the optimal solution in terms of equipment and process know-how.

The market requires a large variety of plate products. Dimensional and metallurgical properties should be kept in narrow tolerances. In very simplified terms, the requirements for new products can be characterized using four criteria: thinner – thicker – wider – harder.

SMS group can help you to reduce the processing steps in order to establish a more efficient production and to cut costs for alloying elements by better mastery of the production processes. This is, where our new X-Roll® MultiFlex-Technology comes into play, especially our new Heat treatment lines (HTL). These facilities complete the heavy plate rolling and enable the economical and energy-efficient production of any steel grades including extremely demanding qualities, like high-strength and ultra-high-strength plates with excellent flatness and precise mechanical properties. These plates are employed in growth sectors such as wind energy, power engineering, tubes and pipelines, mechanical engineering, heavy vehicle engineering, crane technology, and the construction industry.

SMS group is market leader for plate mills with references for the major plate producers worldwide. Beside a vast number of successfully realized mill modernizations and upgrades, since 2005 we supplied 27 new plate lines (22 Plate Mills, 5 Steckel Plate Mills). Also we implemented already 7 heat treatment lines featuring the innovative X-Roll® MultiFlex-Technology.

-

Plate mill

Keep on running

Main dataWe design plate mills for a long run. The individual dimensioning depends on the product mix, the target production amount per year, the product geometries, and the basic conditions of the installation site. The main process sections of any plate mill are: reheating furnaces, mill area with one or two reversing 4-high stands, pre-leveler, plate cooling and hot plate leveler, cooling beds, shearing line, finishing line with cold plate leveler, heavy plate line, and heat treatment line. What prepares our mill design for the long run are opportunities for further development to help you to remain in a leading market position.

![]()

Plate cooling bed -

Steckel/Plate Mills

Maximal flexibility in heavy plate and hot strip rolling

Main dataThe process route enables producing a wide range of products with regard to the material and the product dimensions, i.e. thin and extremely wide plates and thin hot strip. The rolling modes comprise normal rolling, temperature-controlled rolling, thermo-mechanical rolling and multi-plate rolling. The temperature control system in the Steckel/Plate mill allows homogeneous heating of the rolling stock with optimally arranged burners and thus ensures excellent, constant material properties.

State-of-the-art X-Pact® automation and digitalization solutions from SMS group include all process models and control all plants. Through permanent monitoring, documentation and analysis of all process data throughout the entire process, the outstanding product quality is ensured and the process chain is optimized, if required. The world-leading position of SMS group in Steckel Plate mill technology is underlined by 5 greenfield references since 2005.

![]()

The rolling mill with the Steckel furnaces forms the centerpiece of a Steckel/Plate Mill

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Plate rolling

One solution for your complete product range

Heavy plate rolling mills are generating the highest rolling forces among flat rolling mills. With rolling forces of up to 120 MN, SMS group supplied the most powerful plate mill stands worldwide. Actually, today’s production and process requirements go far beyond. The design and the technological level of the mill stands allow continuous adaptations to changing market conditions.

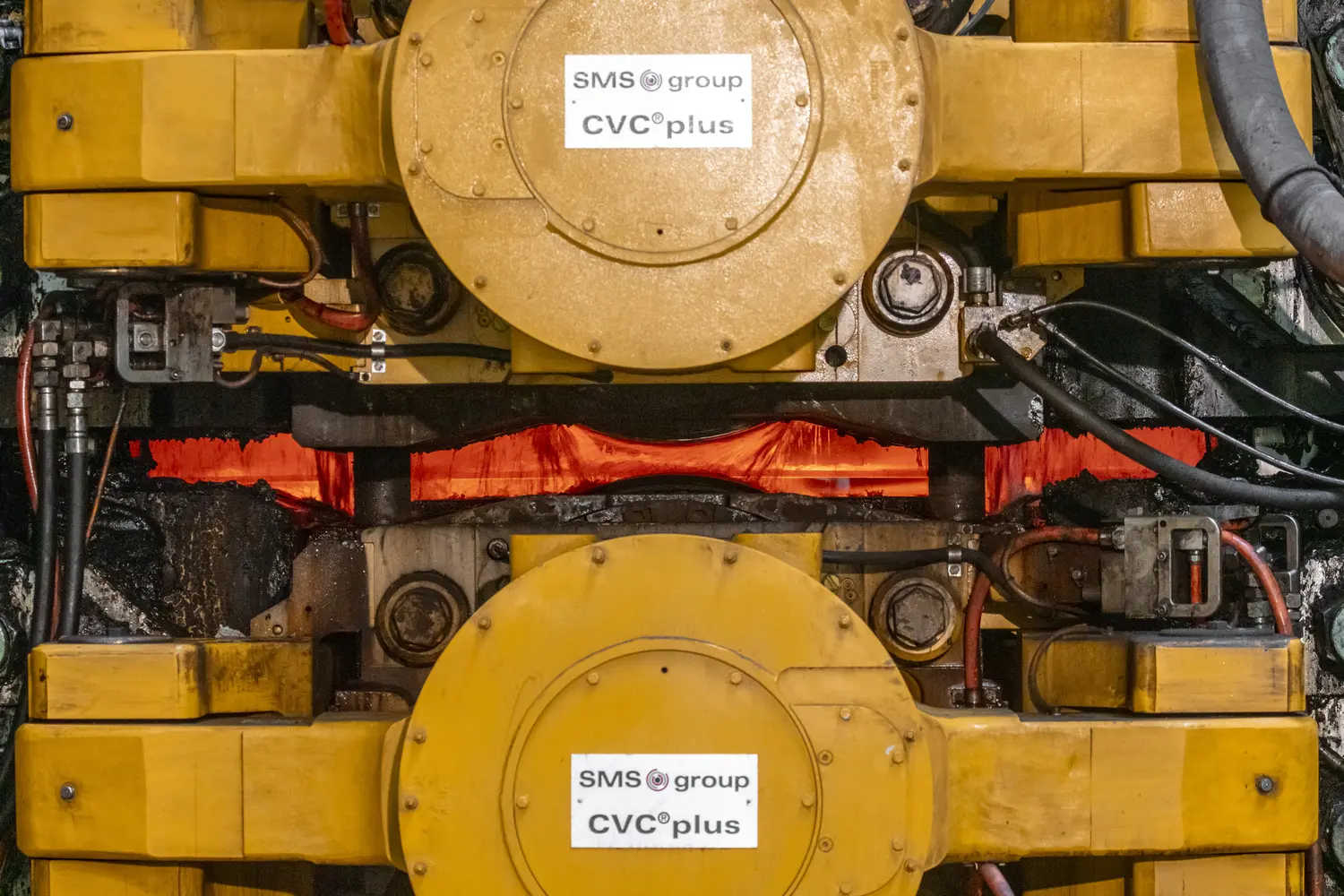

The centerpiece of the mechanical equipment is the CVC® plus technology in combination with the work roll bending system. Our giant torque spindles enable the transmission of high rolling torques and shifting of the work rolls. The design of our mill stands together with our sophisticated actuators ensures that you can roll your entire range of plate products on this plate mill.

![]()

Plate mill stand -

Plate cooling

“The” metallurgical tool in plate production

The optimal plate cooling strategy plays an essential part in setting the required material properties. This is especially true for advanced high strength materials. Our plate cooling systems offer you high cooling rates, flexible cooling strategies and exact control by using a most capable X-Pact® Plate Cooling Control. Our cooling model provides in-bar temperature cooling strategies over the entire plate length and applies true-to-life material models and algorithms to formulate temperature equations, in this way precisely determining the temperature distribution and microstructure components, and ultimately the mechanical properties.

![]()

-

Plate leveling

X-Roll® MultiFlex Leveler - Solution for maximum flexibility

In addition to high-strength material properties, the market nowadays demands excellent flatness and low internal stresses in the plates. The new X-Roll® Multi-Flex-Leveler is setting new standards in terms of final flatness and residual stress distribution in the material.

![]()

Excellent levelling results are ensured by our new X-Roll® MultiFlex-Leveler for cold plate -

Shearing

Cutting plate with power and precision

Our heavy-plate shears are designed to cut plates up to 50 mm thickness with exact width and length and excellent edge quality. Cropping, double-side trimming, slitting, and cut-to-length shears all work according to the state-of-the-art rolling-cut principle. Nowadays, by further design development, our shears are able to cut heavy plates up to 70 mm thickness.

![]()

-

Process control

X-Pact® automation for heavy plate mills

Serving the continuous rising market demands in regard to material properties and product performances for plate production, SMS group provides the sophisticated X-Pact® electric and automation system. It covers the full process chain from power distribution and drive systems via measuring systems and sensors and finally the complete basic and process automation including HMI systems. Our customers benefit from optimized productivity and yield, highest quality and excellent operability.

![]()

-

Heat treatment

X-Roll® MultiFlex treatment technology – Customized properties for high-grade plates

Our heat treatment lines (HTL) enable the economical and energy efficient production of a wide range of special steel grades with extremely demanding qualities. These plates are employed in growth sectors such as wind energy, power engineering, tubes and pipelines, mechanical engineering, heavy vehicle engineering and more.

Our flexible, future-oriented overall concept is based on proven and innovative system components. Especially our X-Roll® MultiFlex-Quench is setting standards for plate production. By predicting the mechanical properties with the material property model for the entire heat treatment process, operators can optimize the whole process and develop new products in a cost-effective way. We supply the entire process chain from a single source and thus the highest quality.

![]()

The art of heating and cooling is essential for achieving the required product properties and quality -

Finishing with CVC® plus

Integrated work roll shifting and bending

The combination of bending and axial shifting of the work rolls with special CVC® plus grinding and the technical process model PFC® (profile and flatness control) makes the efficiency of the CVC® technology.

![]()

CVC® plus technology ensures efficient and high grade rolling -

X-Roll® MultiFlex-Quench

New cooling standard for plate production

The high degree of flexibility, the broad product portfolio and the excellent flatness results offered by the X-Roll® MultiFlex-Quench are setting new standards for plate production in heat treatment lines. Flexible cooling strategies enable the production of standard and special materials as well as newly developed grades with the highest quality requirements.

![]()

The X-Roll® MultiFlex-Quench is the “heart” of the HTL -

X-Roll® MultiFlex-Turnover Device

Silent and surface friendly heavy plate handling

Plate turnover devices are part of the equipment in heavy plate finishing lines. Our innovative X-Roll® MultiFlex-Turnover device is characterized by low-noise operation, surface-friendly handling of plates and by the expansion of the operating area.

![]()

Turning arms flexibly adapted to the respective plate thickness

Services for this plant

Sorry, there are no results for the search term.